Process and device for realizing up-to-standard emission of boiler flue gas with coupling technology

A boiler flue gas and mixing device technology, which is applied in the field of flue gas purification, can solve the problems of not considering the difference in ozone reaction rate, new land occupation, large energy consumption, and complex transformation system, so as to achieve enhanced NO2 removal effect and transformation The effect of small workload and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

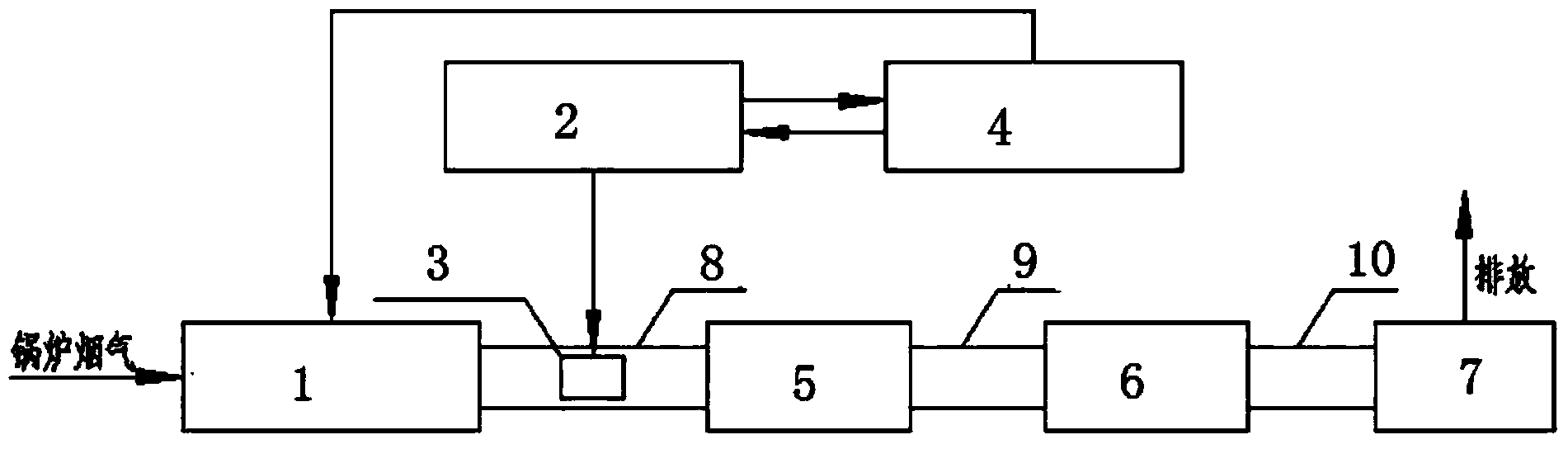

[0031] Such as figure 1 As shown, a device that utilizes coupling technology to realize boiler flue gas discharge up to standard includes an electrostatic synergistic dust collector 1, and the electrostatic synergistic dust collector 1 is connected to the induced draft fan 5 through the flue I, and the other part of the induced draft fan 5 is One end is connected to the inlet of the desulfurization tower 6 through the flue II, and the outlet of the desulfurization tower 6 is connected to the chimney 7 through the flue III; a mixing device 3 is arranged in the flue I, and the ozone generating device 2 is connected to the The mixing device 3 is connected, and the process water tank 4 is respectively connected with the electrostatic synergistic electrostatic precipitator 1 and the ozone generator 2 through the water pipeline.

[0032] The electrostatic precipitator 1 of the present invention still retains the main body of the electrostatic precipitator, which is mainly used to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com