Coolant additive for reducing benzene emission, production method and using method

A cooling liquid and additive technology, applied in fuel additives, liquid carbon-containing fuels, petroleum industry, etc., can solve the problems of inconspicuous effect and repeated addition, and achieve obvious effect, promote combustion, and reasonable market price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

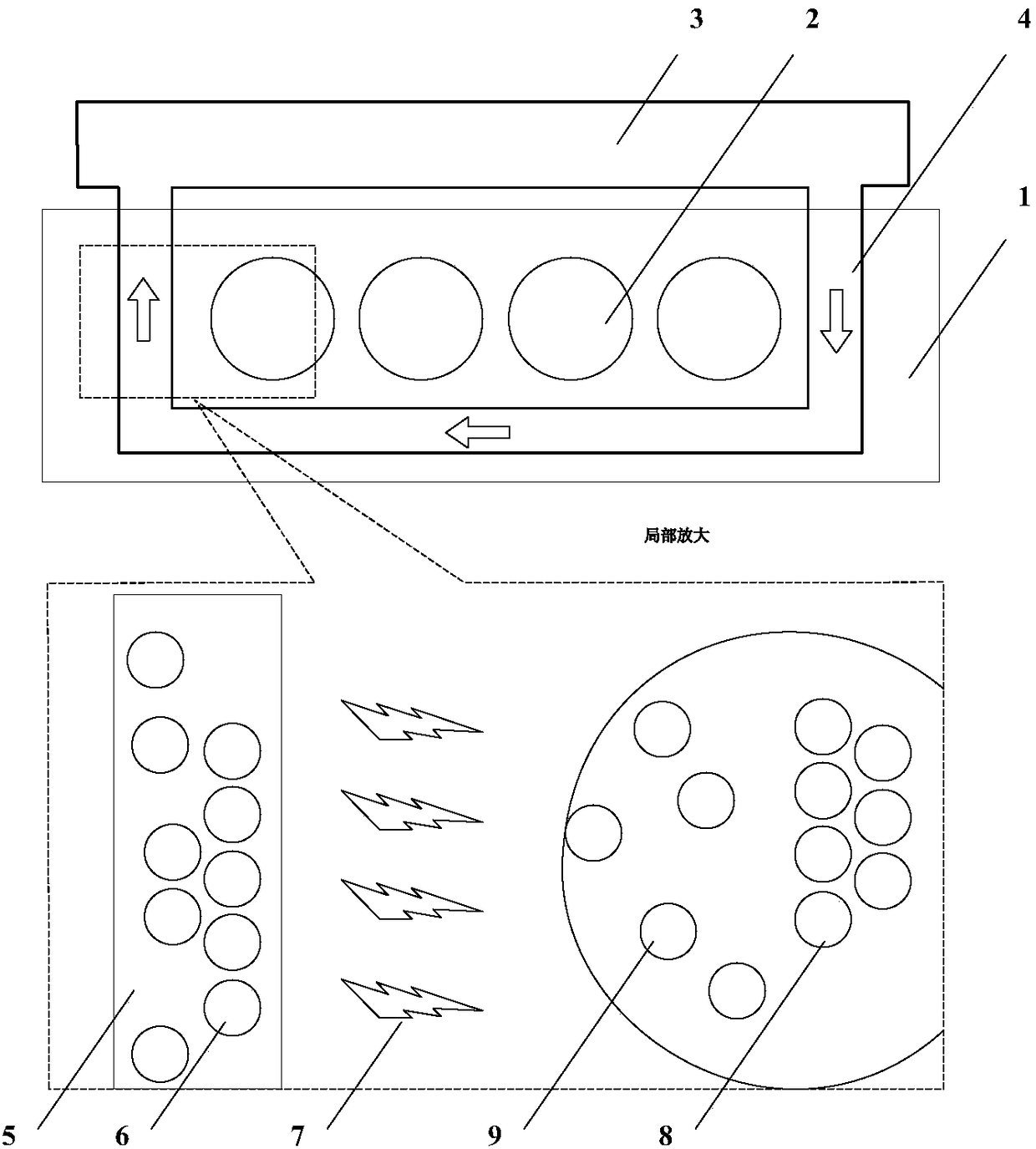

Image

Examples

Embodiment 1

[0022] A kind of coolant additive that reduces benzene emissions involved in the present embodiment, comprises the SiO of 47 parts by mass 2 ; 15 parts by mass of Al 2 o 3 ; 10 parts by mass of Fe 2 o 3 ; 4.5 parts by mass of MgO; 45 parts by mass of CaCO 3 ; 2.5 parts by mass of TiO 2 ; 0.5 parts by mass of MnO; 0.5 parts by mass of rare earth elements.

Embodiment 2

[0024] A kind of cooling liquid additive that reduces benzene emission involved in this embodiment, comprises: the SiO of 75 parts by mass 2 ; 12 parts by mass of Al 2 o 3 ; 3.0 parts by mass of Fe 2 o 3 ; 1.0 parts by mass of MgO; 20 parts by mass of CaCO 3 ; 0.1 parts by mass of TiO 2 ; 0.05 parts by mass of MnO; 0.05-0.5 parts by mass of rare earth elements.

Embodiment 3

[0026] A kind of cooling liquid additive that the present embodiment relates to reduces the emission of benzene, comprising: the SiO of 63 parts by mass 2 ; 13 parts by mass of Al 2 o 3 ; 7 parts by mass of Fe 2 o 3 ; 3 parts by mass of MgO; 35 parts by mass of CaCO 3 ; 1.5 parts by mass of TiO 2 ; 0.2 parts by mass of MnO; 0.2 parts by mass of rare earth elements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com