Positive-pressure-injecting type fully-premixed combustion heating device

A combustion heating and injection technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of high cost, complex mixing system, high total investment and cost of gas heating system, and achieve low cost and volume Small, break through the effect of technology monopoly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

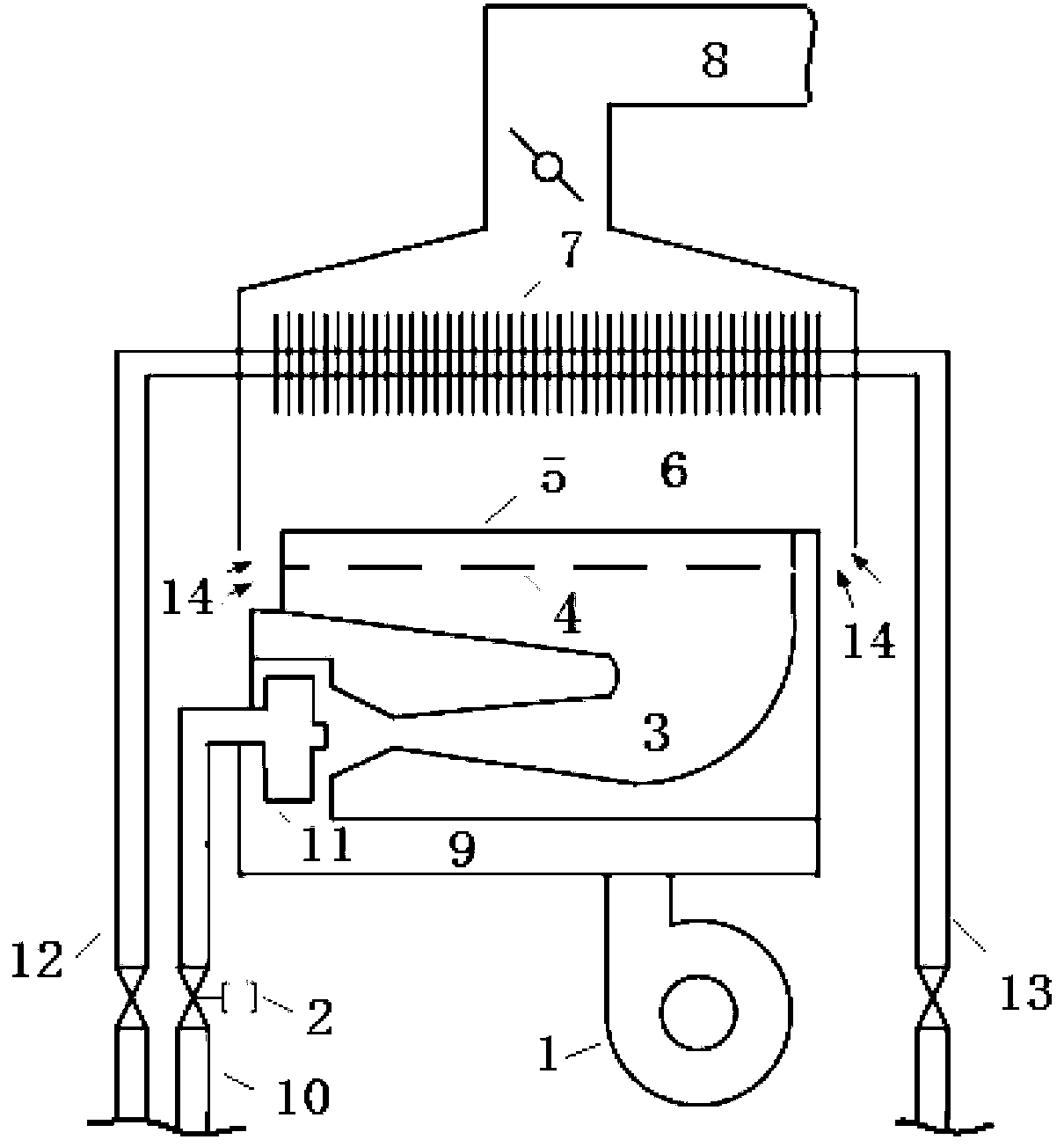

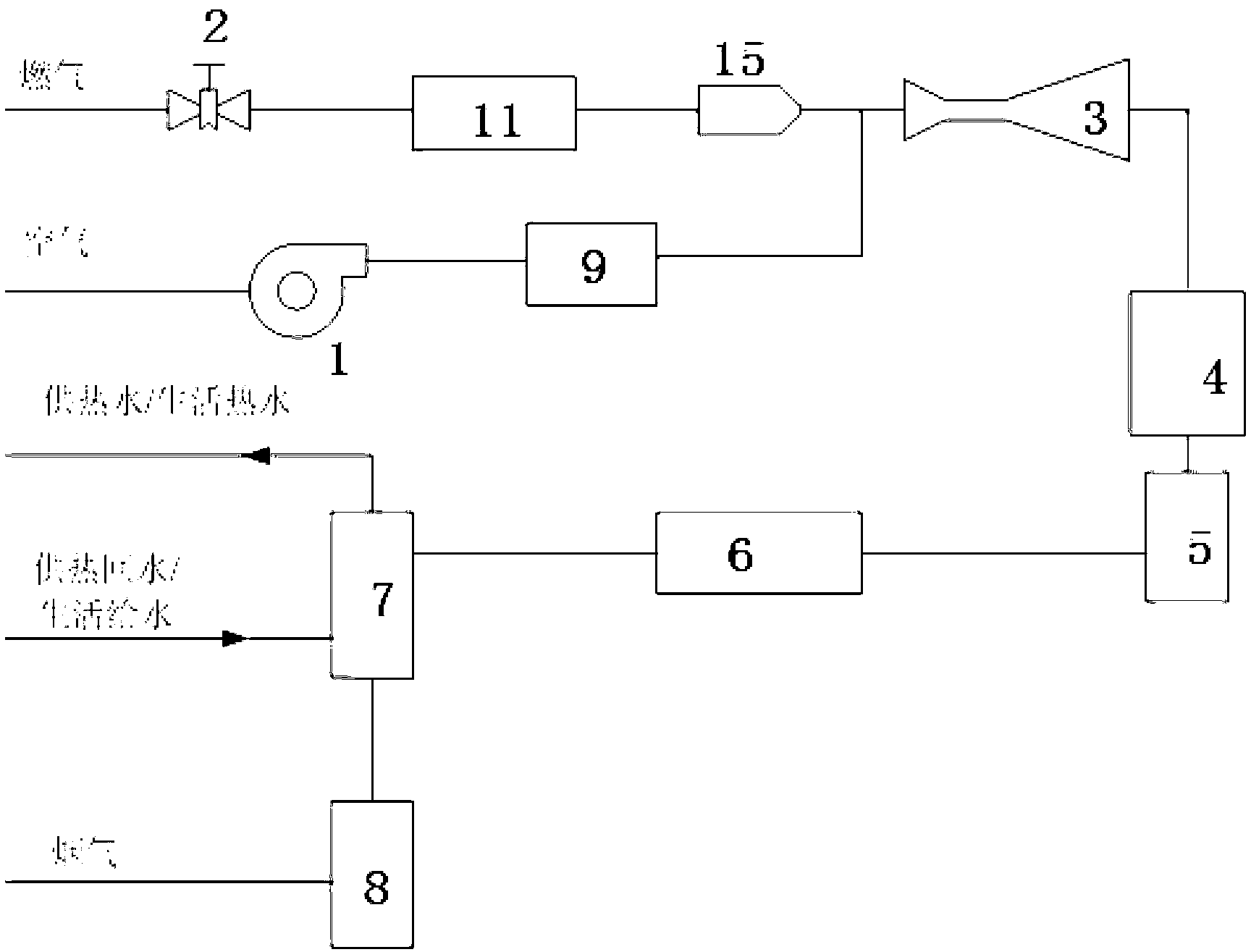

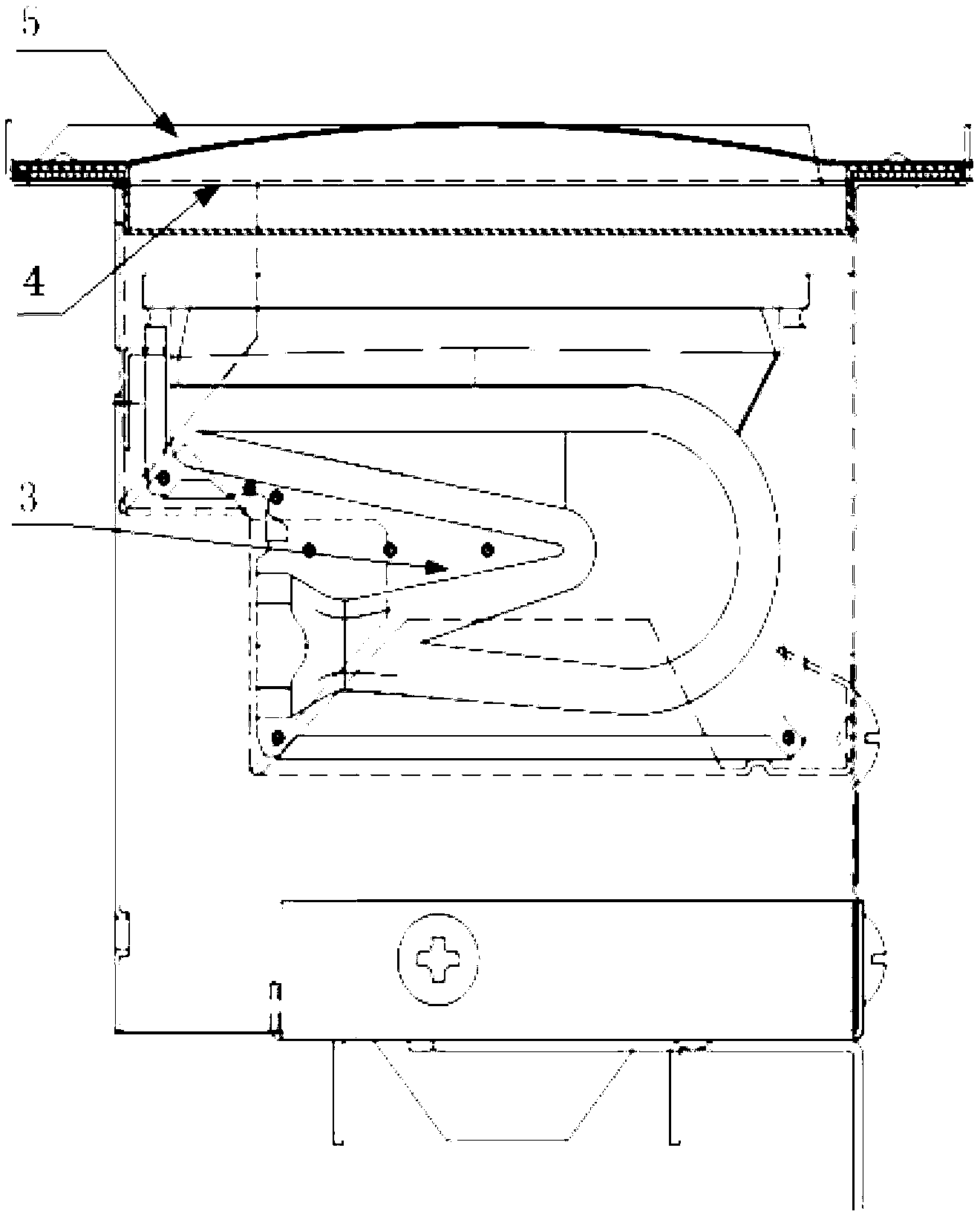

[0030] The present invention is specifically applied in the gas water heater system, the gas water heater mainly provides domestic hot water, and its structural diagram is as follows figure 1 As shown, the main components include a fully premixed burner, a copper finned heat exchanger 7, a gas solenoid valve 2, and a DC fan for fan 1. The heat load of the gas water heater system is 22kW, and the specific structure diagram of the fully premixed burner is shown in image 3 , wherein, 3 is an injection mixer, 4 is a distribution orifice, and 5 is a fire orifice. The interior of the fully premixed burner contains 11 injection mixers 3. The structural dimensions of the injection mixer are shown in Figure 4 , wherein, 9 is an air distribution pipe, 15 is a gas nozzle, 16 is a shrinkage pipe, and 17 is a diffuser pipe; the structure of the gas nozzle 15 is detailed in Figure 5 , the structural form of the fire hole plate 5 is as follows Figure 6 shown. After experimental verifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com