Magnetic-red mixed lean iron ore pre-concentration technology

A technology of iron ore and process, which is applied in the field of pre-selection of magnetic-red mixed lean iron ore and magnetic-red mixed lean iron ore, which can solve the problem of poor separation effect of fine-grained grade, deterioration of separation index, and equipment Difficulty in configuration and other problems, to achieve obvious effect of emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

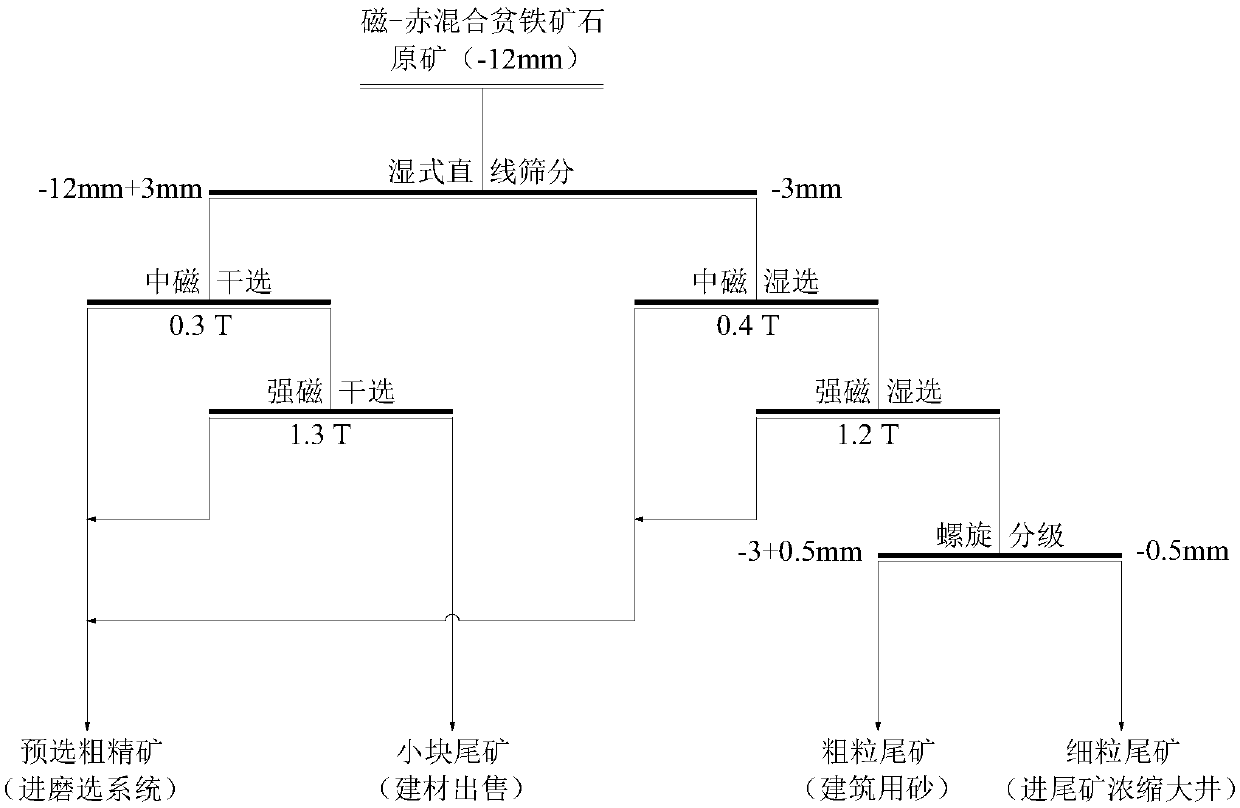

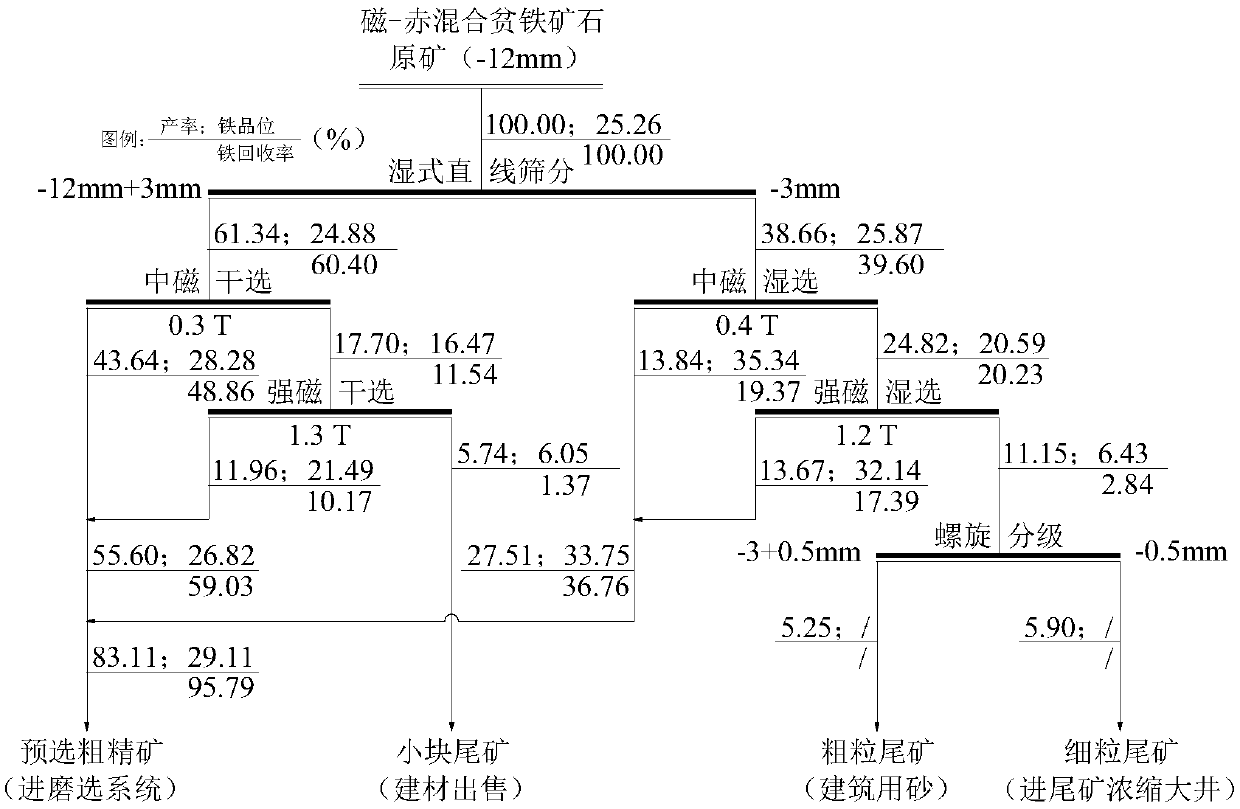

[0034] Such as figure 1 and figure 2 As shown, a kind of pre-selection process of magnetic-red mixed lean iron ore of the present embodiment comprises the following steps:

[0035] a. The magnetic-red mixed lean iron ore (-300mm) extracted from underground mining and lifted up is crushed into a finely crushed product of -12mm through three sections and one closed circuit; the TFe grade of the magnetic-red mixed lean iron ore is 20 -30%, the TFe grade in this embodiment is 25%; the ore with an iron grade below 20% still does not have the conditions for development and utilization under the current mining situation, and the ore with an iron grade above 30% usually directly adopts grinding technology. Embodiment Carry out follow-up pre-selection process for ore with TFe grade at 20-30%;

[0036] b. Screen the finely crushed product through a wet linear sieve to obtain two particle grades of -12+3mm and -3mm, and adopt different pre-selection methods for the particle size chara...

Embodiment 2

[0047] The preselection process of a kind of magnetic-red mixed lean iron ore of this embodiment is basically the same as embodiment 1, the difference is that the TFe grade of magnetic-red mixed lean iron ore is 20% in the present embodiment, step b The linear sieve sieve plate adopted in is a perforated steel sieve plate, and the sieve hole size is 5mm; in the step c, the -3mm particle size product adopts a wet permanent magnetic drum type medium magnetic separator for medium magnetic separation, and the magnetic field strength is 0.5T. The magnetic separation tailings flow into the large particle vertical ring pulsating high gradient strong magnetic separator for strong magnetic separation with a magnetic field strength of 1.3T; in step d, the -12+3mm grain grade products are transported to the permanent magnetic cylinder type medium magnetic field dry by belt The separator carries out medium magnetic dry separation, and the magnetic field strength is 0.4T, and the middle mag...

Embodiment 3

[0049] The preselection process of a kind of magnetic-red mixed lean iron ore of the present embodiment is basically the same as embodiment 1, the difference is that the TFe grade of the magnetic-red mixed lean iron ore in the present embodiment is 30%, step b The linear sieve sieve plate adopted in is a perforated steel sieve plate, and the sieve hole size is 4mm; the -3mm particle size product in step c adopts a wet permanent magnet drum type medium magnetic separator for medium magnetic separation, and the magnetic field strength is 0.6T. The magnetic separation tailings flow into the large particle vertical ring pulsating high-gradient strong magnetic separator for strong magnetic separation with a magnetic field strength of 1.4T; in step d, the -12+3mm grain grade products are transported to the permanent magnetic cylinder type medium magnetic field dry by belt The separator carries out medium magnetic dry separation, and the magnetic field strength is 0.5T, and the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com