Harmless domestic sludge pyrolysis and carbonization treatment technique

A domestic sludge and carbonization treatment technology, which is applied in the directions of dehydration/drying/concentrated sludge treatment, pyrolysis treatment sludge, etc., can solve the problems of rheological process control difficulties, affecting the continuous production of the treatment system, etc., and achieve construction investment Low, low self-energy, low working condition requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

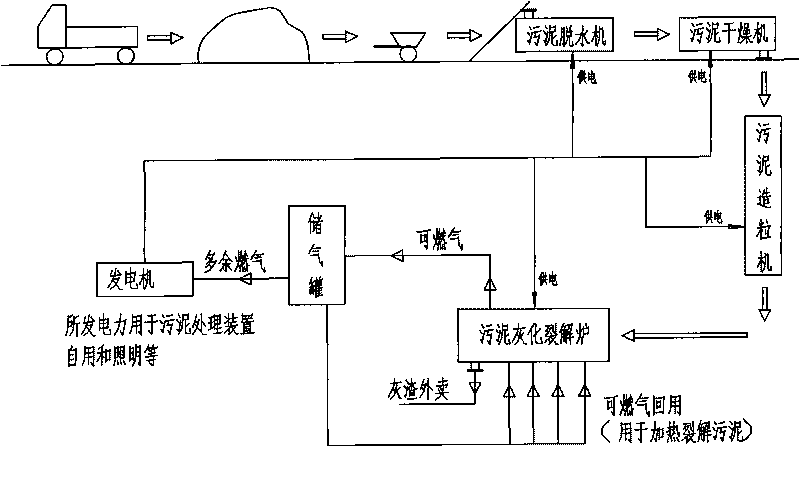

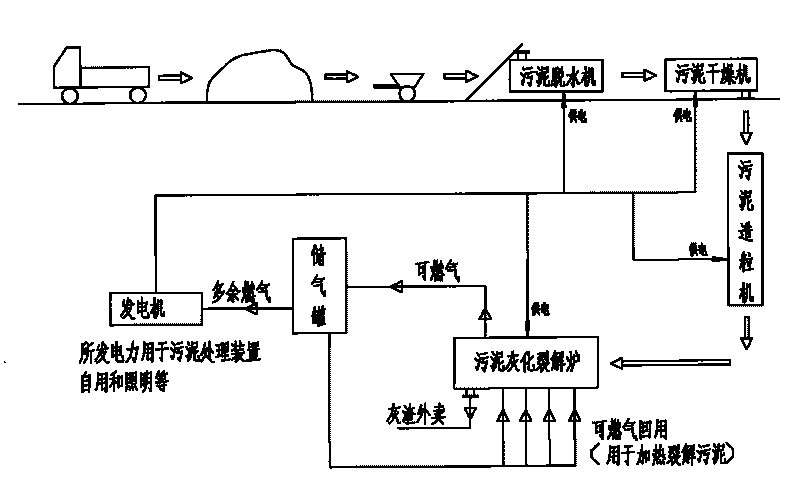

[0026] Such as figure 1 Shown: the domestic sludge harmless cracking and carbonization treatment process of the present invention, the specific steps are as follows: the domestic sludge after the simple pre-stage premixing and standing treatment is sent to the special dehydration equipment for pre-dehydration through a special conveying machine; Send the semi-dry sludge after pre-dehydration treatment to the hot air granulation system for forming dehumidification and granulation; send the formed sludge granules to the high-level kettle through the conveying system for re-dehumidification treatment; The domestic sludge is introduced into the pre-reaction tank through the rotary conveyor for pre-reaction; the pre-reacted sludge is then introduced into the pre-cracking gasifier through the conveying controller for pre-fission reaction with specially configured TCS additives; the pre-reaction The material after the thermal fission pre-reaction is introduced into the final cracking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com