Down-hole horizontal hole exploitation system for mixing gas displacing coal gas, and the method

A technology of mixing gas and coalbed methane, which is applied in the fields of mining fluids, mining equipment, earthwork drilling, etc., can solve problems such as the effect of underground coalbed methane mining needs to be improved, the economy of coalbed methane is affected, and it is not suitable for low-permeability coal seams. Significant emission reduction effect, reducing the risk of gas outburst and coal seam outburst, reducing the effect of gas outburst risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

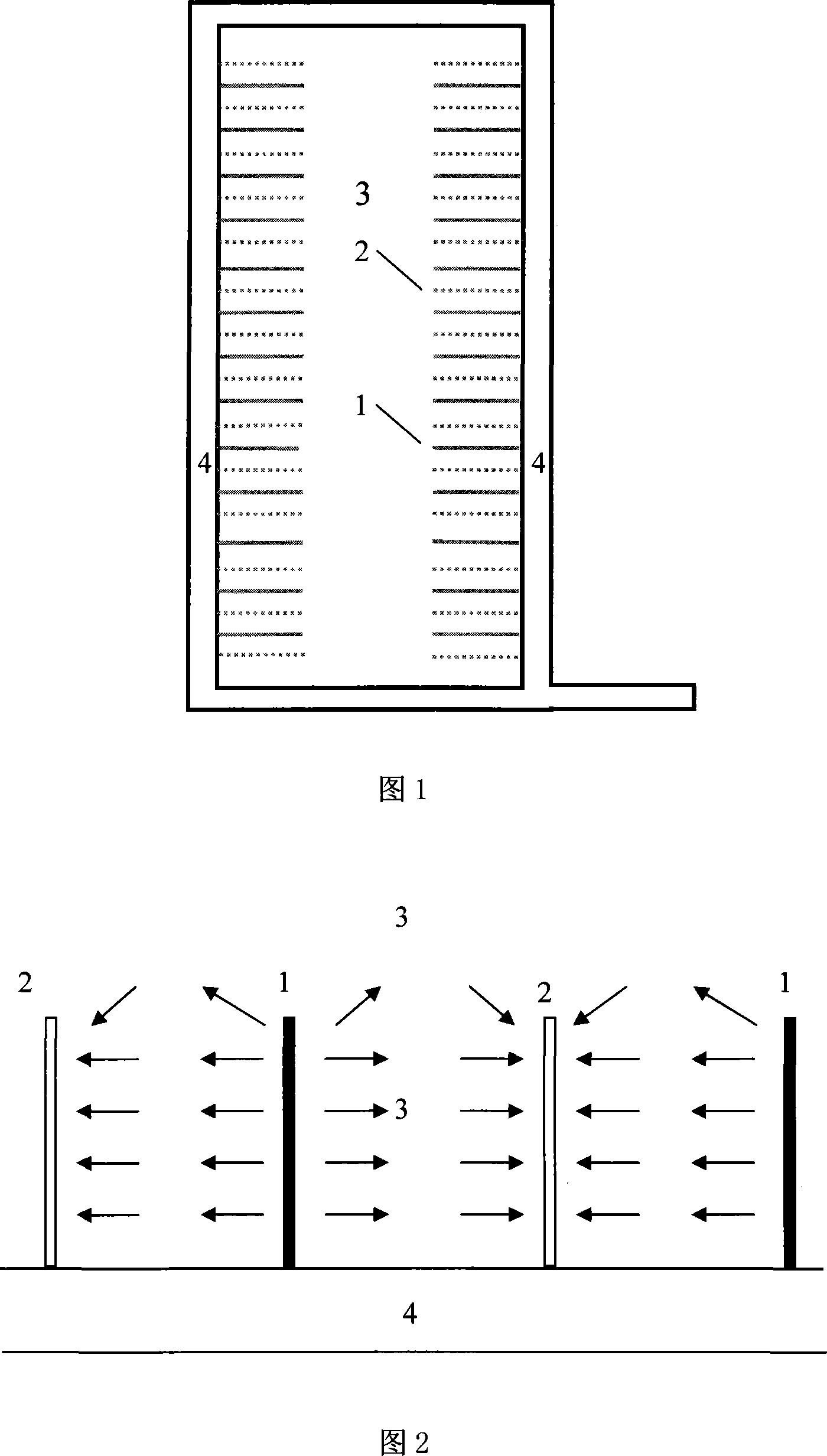

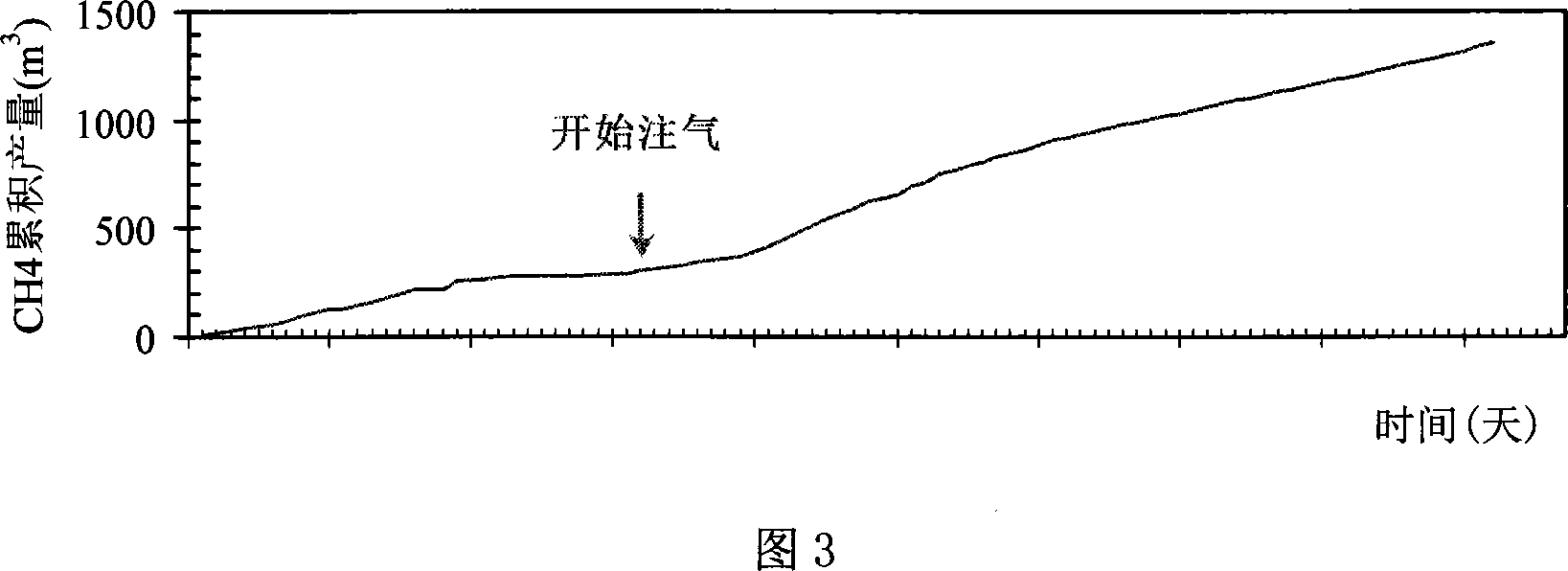

[0046] 1. The mining system

[0047] Drilling is used to form injection holes (1) in the coal seam roadway (4), and hole sealing measures are used to seal the holes (applicable to high pressure conditions); meanwhile, coalbed gas extraction holes (2) are formed in the roadway (4). The distance between the injection hole (1) and the drainage hole (2) is 1m to 10m, and the specific distance depends on the width of the mining area, the gas discharge time of the mining area and the permeability of the coal seam. For the current state of the coal mining area, 3 to 5m is the most economical spacing.

[0048] 2. This mining method

[0049] 1. About step ①:

[0050] Mix various gases in a certain proportion to form a mixed gas;

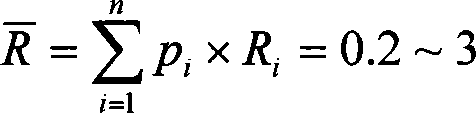

[0051] The ratio is calculated according to the following formula:

[0052] R - = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com