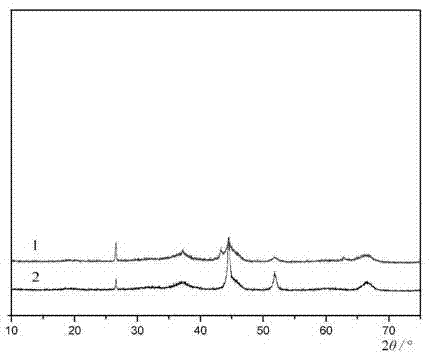

Methanation catalyst for synthesizing substitute natural gas and preparation method thereof

A methanation catalyst, a technology for replacing natural gas, applied in physical/chemical process catalysts, catalyst carriers, chemical instruments and methods, etc., can solve the problems of low volume space velocity, low use space velocity, and no research on methanation catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

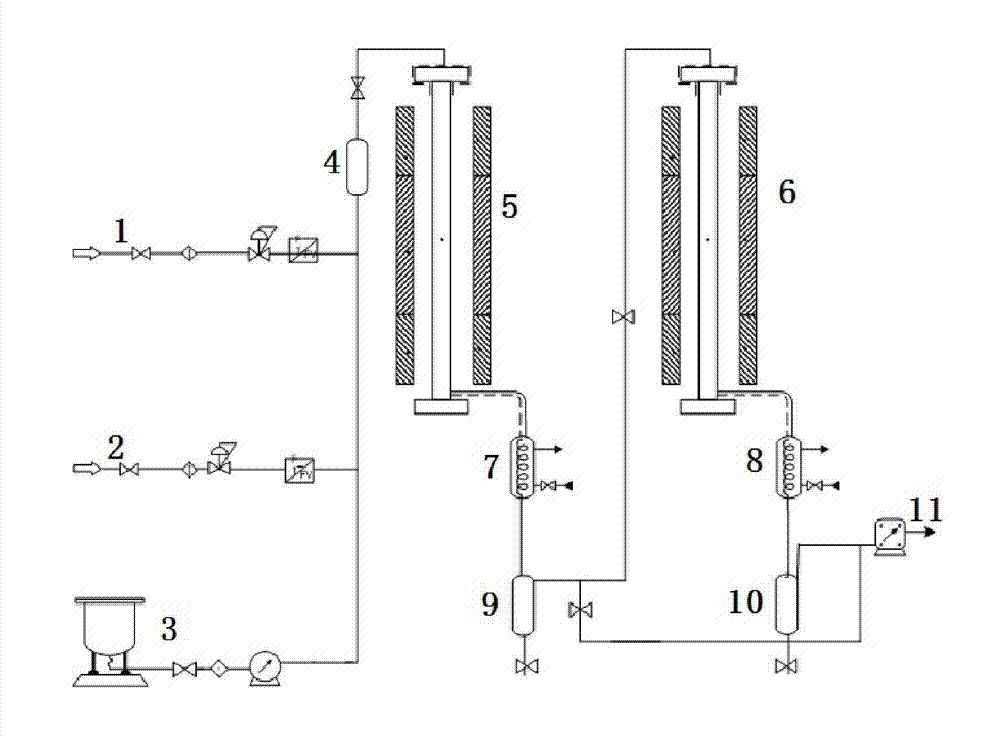

Method used

Image

Examples

Embodiment 1

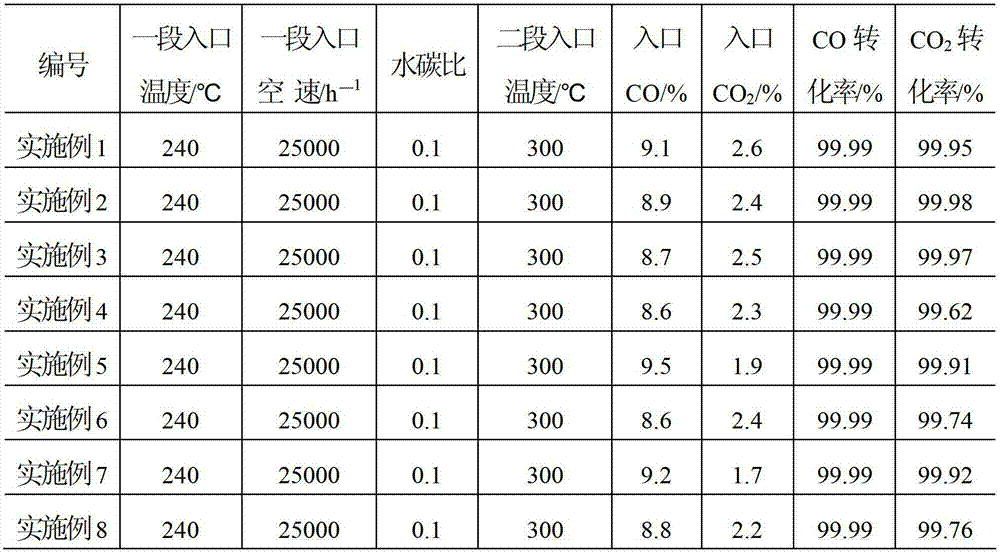

[0127] Embodiment 1: the preparation of methanation catalyst

[0128] The implementation steps of this embodiment are as follows:

[0129] A. Catalyst carrier preparation

[0130] Al(NO 3 ) 3 9H 2 O and Mg(NO 3 ) 2 ·6H 2 O is added with water to prepare a solution with a total equivalent concentration of metal ions of 0.1 mol / L, in which Al(NO 3 ) 3 9H 2 O and Mg(NO 3 ) 2 ·6H 2 The weight ratio of O is 40:12.7, then add 1% sodium dodecylbenzenesulfonate oxygen-containing organic matter based on the total weight of the aluminum nitrate hydrate and magnesium nitrate hydrate, stir evenly, and heat the mixture to temperature 30°C, then add 0.1N Na 2 CO 3 Precipitating agent, so that the pH at the end point reaches 7.0, the generated precipitate is washed with water, and the washed precipitate is then dried at a temperature of 80°C for 6 hours, and then roasted at a temperature of 400°C for 3 hours, and the roasted precipitate is cooled after cooling. Pulverize, take 1...

Embodiment 2

[0140] Embodiment 2: the preparation of methanation catalyst

[0141] The implementation steps of this embodiment are as follows:

[0142] A. Catalyst carrier preparation

[0143] Al(NO 3 ) 3 9H 2 O and Mg(NO 3 ) 2 ·6H 2 O is added with water to prepare a solution with a total equivalent concentration of metal ions of 0.2 mol / L, in which Al(NO 3 ) 3 9H 2 O and Mg(NO 3 ) 2 ·6H 2 The weight ratio of O is 32:9, then add 2.5% sodium dodecylbenzenesulfonate oxygen-containing organic matter based on the total weight of the aluminum nitrate hydrate and magnesium nitrate hydrate, stir well, and heat the mixture to the temperature 35°C, then add 0.3N Na 2 CO 3 Precipitating agent, so that the pH at the end point reaches 7.0, the generated precipitate is washed with water, the washed precipitate is then dried at a temperature of 85°C for 6.5 hours, and then roasted at a temperature of 500°C for 3.5 hours, and the roasted precipitate is cooled after cooling. Pulverize, tak...

Embodiment 3

[0153] Embodiment 3: the preparation of methanation catalyst

[0154] The implementation steps of this embodiment are as follows:

[0155] A. Catalyst carrier preparation

[0156] Al(NO 3 ) 3 9H 2 O and Mg(NO 3 ) 2 ·6H 2 O is added with water to prepare a solution with a total equivalent concentration of metal ions of 0.5 mol / L, in which Al(NO 3 ) 3 9H 2 O and Mg(NO 3 ) 2 ·6H 2 The weight ratio of O is 34:7.5, then add 4% cellulose oxygen-containing organic matter based on the total weight of the aluminum nitrate hydrate and magnesium nitrate hydrate, stir evenly, heat the mixture to a temperature of 90°C, and then add 0.8 N NaOH precipitating agent, so that the pH at the end point reaches 9.5, and the generated precipitate is washed with water. The washed precipitate is then dried at a temperature of 120°C for 12 hours, and then roasted at a temperature of 900°C for 6 hours. After cooling, the roasted precipitate The material is pulverized, and the 120-140 mesh p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com