Method for preparing agglomeration liquid for restraining iron mine sintering flue gas fine particle emissions

A technology for sintering flue gas and fine particles, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as complex flue gas components, large flue gas flow rates, and complex components, and achieve effective collision probability. The effect of accelerating the speed of reunion and improving the efficiency of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

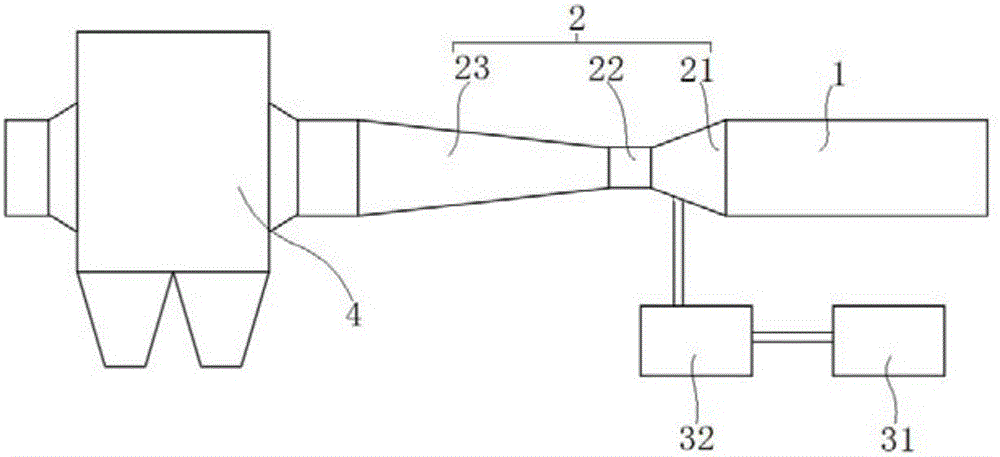

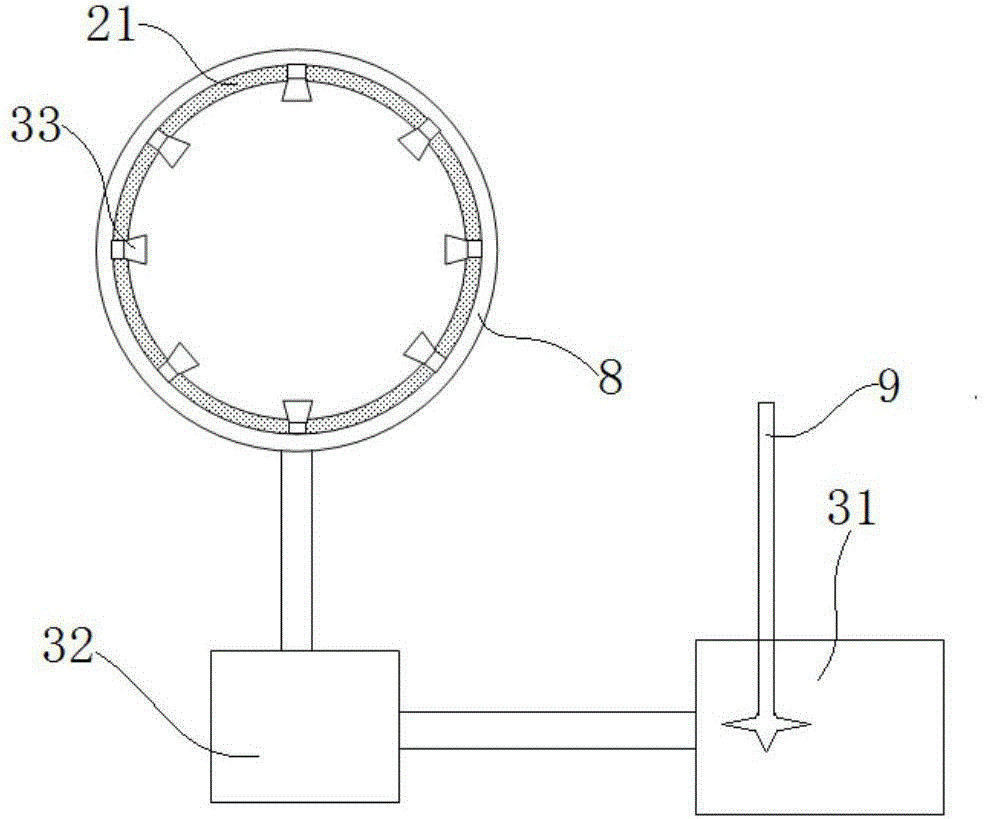

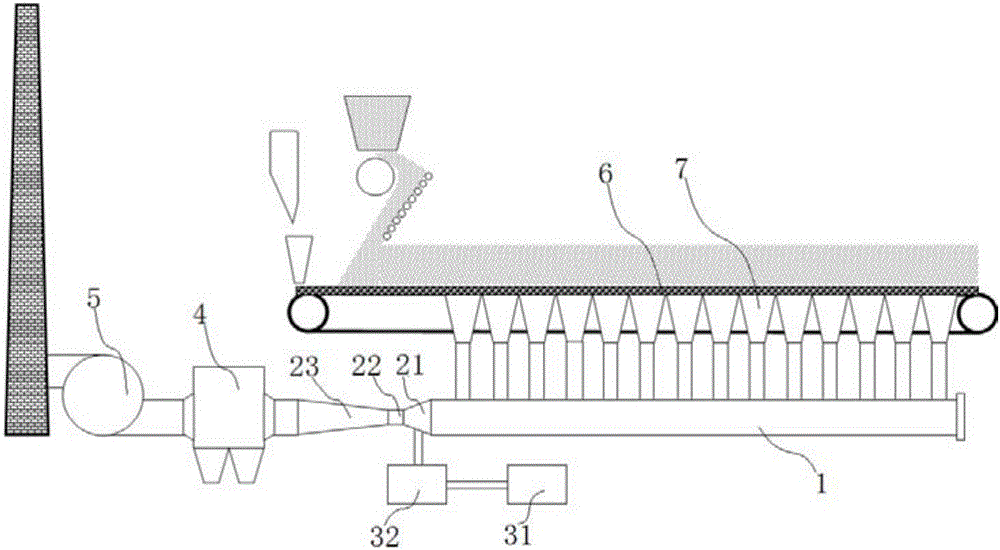

[0058] combine Figure 4 and Figure 5 As shown, the preparation method of the agglomeration liquid that suppresses the emission of fine particulate matter in iron ore sintering flue gas in this embodiment is: a composite agglomerating agent for emission reduction of fine particulate matter in flue gas, and each component is composed according to the following mass: polyaluminum chloride 10g, carboxymethyl Sodium cellulose base 30g, polyacrylamide 30g, additive 2g. The additive is a solid additive, and the additive is composed of activated carbon and coke powder. The additive is composed of the following mass percentages: 90% activated carbon and 10% coke powder. 100μm, coke powder particle size requirement: 74μm≤coke powder particle size≤100μm.

[0059] The preparation method of the present embodiment reunion liquid is:

[0060] (A) Weigh 10 g of polyaluminum chloride, 30 g of sodium carboxymethyl cellulose, and 30 g of polyacrylamide in parts by mass, and mix 10 g of soli...

Embodiment 2

[0107] The basic content of this embodiment is the same as that of Example 1, except that the additive is composed of activated carbon and zeolite, and the additive is composed of the following mass percentages: 85% of activated carbon and 15% of zeolite, and the particle size of the activated carbon requires: 74μm≤activated carbon particle size≤100μm, zeolite particle size requirement: 74μm≤zeolite particle size≤100μm.

[0108] Detect the emission concentration of PM2.5 and PM10 in the sintering flue gas after the dust removal device 4, and calculate the emission reduction efficiency of PM2.5 and PM10. The emission reduction efficiency of PM2.5 is 56.4%, and the emission reduction efficiency of PM10 is 49.0%.

Embodiment 3

[0110] The basic content of this embodiment is the same as that of Example 1, except that the additive is composed of activated carbon and zeolite, and the additive is composed of the following mass percentages: 95% of activated carbon and 5% of zeolite.

[0111] Detect the emission concentration of PM2.5 and PM10 in the sintering flue gas after the dust removal device 4, and calculate the emission reduction efficiency of PM2.5 and PM10. The emission reduction efficiency of PM2.5 is 60.2%, and the emission reduction efficiency of PM10 is 48.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com