A method for reducing emission of pm10 and pm2.5 of iron ore sintering flue gas

A technology of sintering flue gas and PM10, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as complex composition, complex flue gas composition, and large flue gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

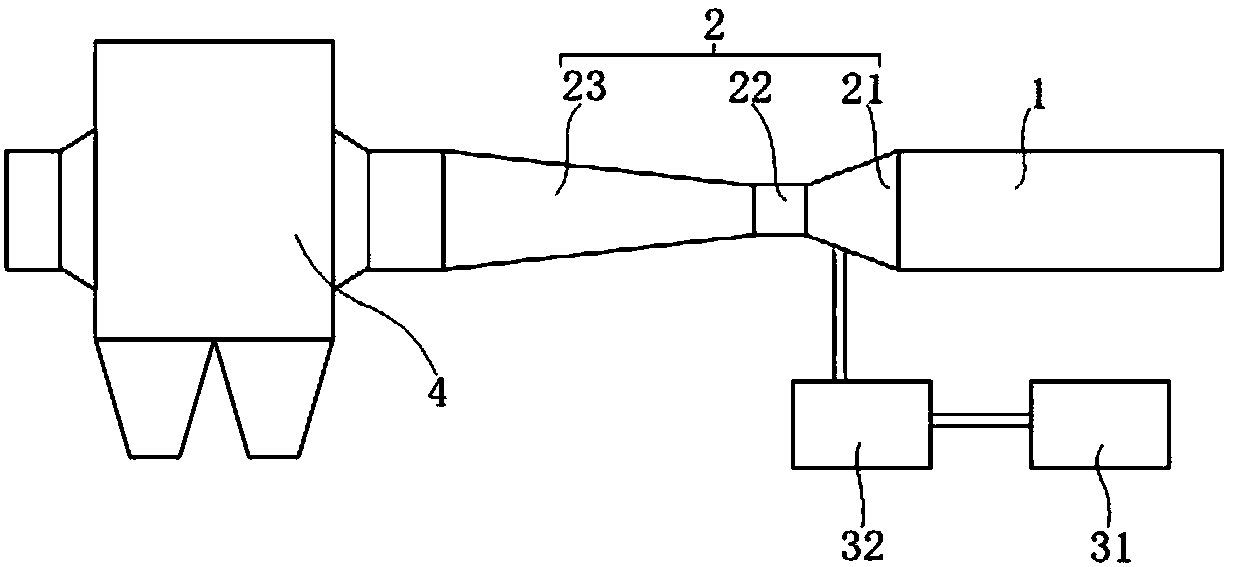

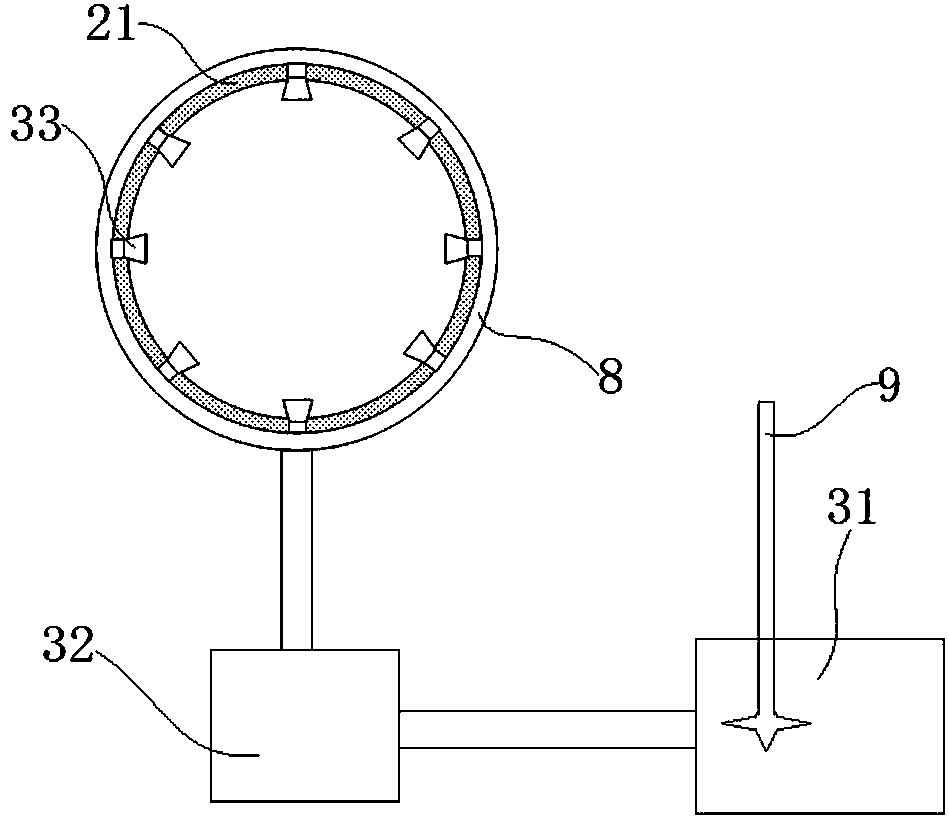

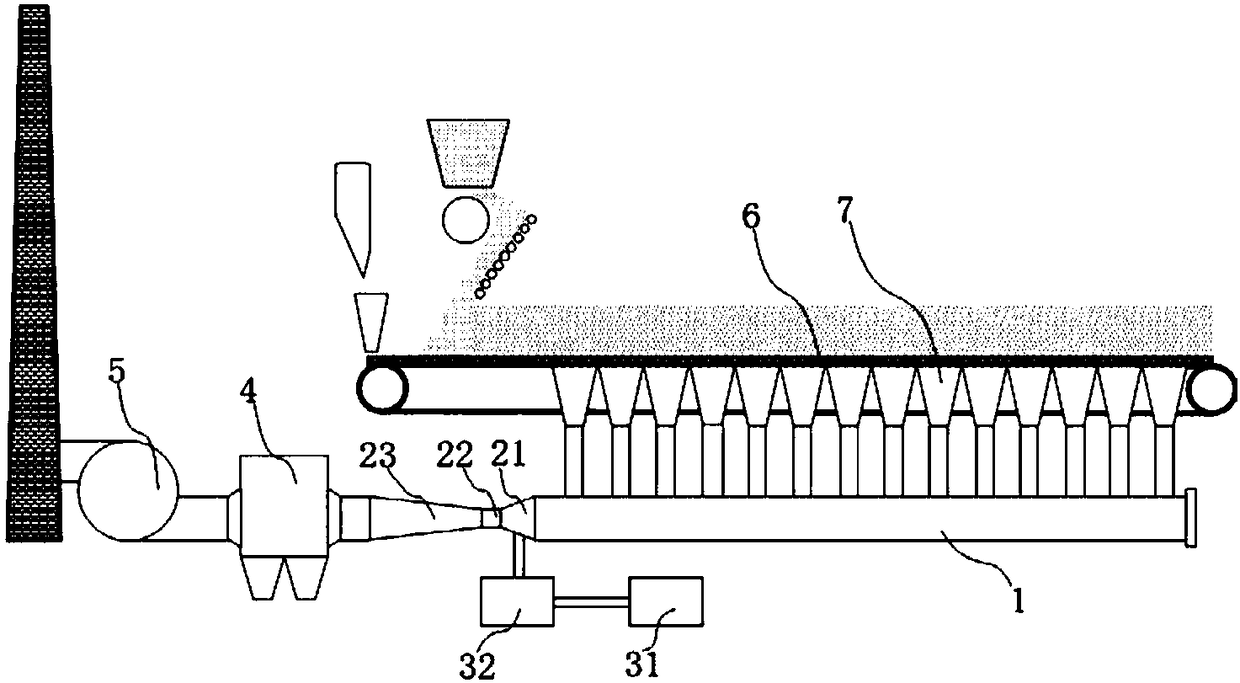

[0058] combine Figure 10 and Figure 11 As shown, the emission reduction method of a kind of iron ore sintering flue gas PM10 and PM2.5 in the present embodiment: in the process of iron ore sintering, the agglomeration liquid is sprayed into the flue gas channel of the sintering flue gas, and the fine particles in the sintering flue gas Agglomerates and grows under the action of the agglomeration liquid, and adopts the dust removal device 4 to remove the fine particles that agglomerate and grow.

[0059] The composite agglomerating agent for emission reduction of fine particles of flue gas consists of the following components: 10 g of polyaluminum chloride, 30 g of sodium carboxymethyl cellulose, 30 g of polyacrylamide, and 2 g of additives. The additive is a solid additive, and the additive is composed of activated carbon and coke powder. The additive is composed of the following mass percentages: 90% activated carbon and 10% coke powder. 100μm, coke powder particle size r...

Embodiment 2

[0108] The basic content of this embodiment is the same as that of Example 1, except that the additive is composed of activated carbon and zeolite, and the additive is composed of the following mass percentages: 85% of activated carbon and 15% of zeolite, and the particle size of the activated carbon requires: 74μm≤activated carbon particle size≤100μm, zeolite particle size requirement: 74μm≤zeolite particle size≤100μm.

[0109] Detect the emission concentration of PM2.5 and PM10 in the sintering flue gas after the dust removal device 4, and calculate the emission reduction efficiency of PM2.5 and PM10. The emission reduction efficiency of PM2.5 is 56.4%, and the emission reduction efficiency of PM10 is 49.0%.

Embodiment 3

[0111] The basic content of this embodiment is the same as that of Example 1, except that the additive is composed of activated carbon and zeolite, and the additive is composed of the following mass percentages: 95% of activated carbon and 5% of zeolite.

[0112] Detect the emission concentration of PM2.5 and PM10 in the sintering flue gas after the dust removal device 4, and calculate the emission reduction efficiency of PM2.5 and PM10. The emission reduction efficiency of PM2.5 is 60.2%, and the emission reduction efficiency of PM10 is 48.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com