Chemical agglomeration liquid, preparation method and applications thereof, and device

A technology of chemical agglomeration and liquid storage, which is applied in the field of chemical agglomeration liquid, which can solve the problems of low removal efficiency and achieve the effects of simple ingredients, improved agglomeration effect, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

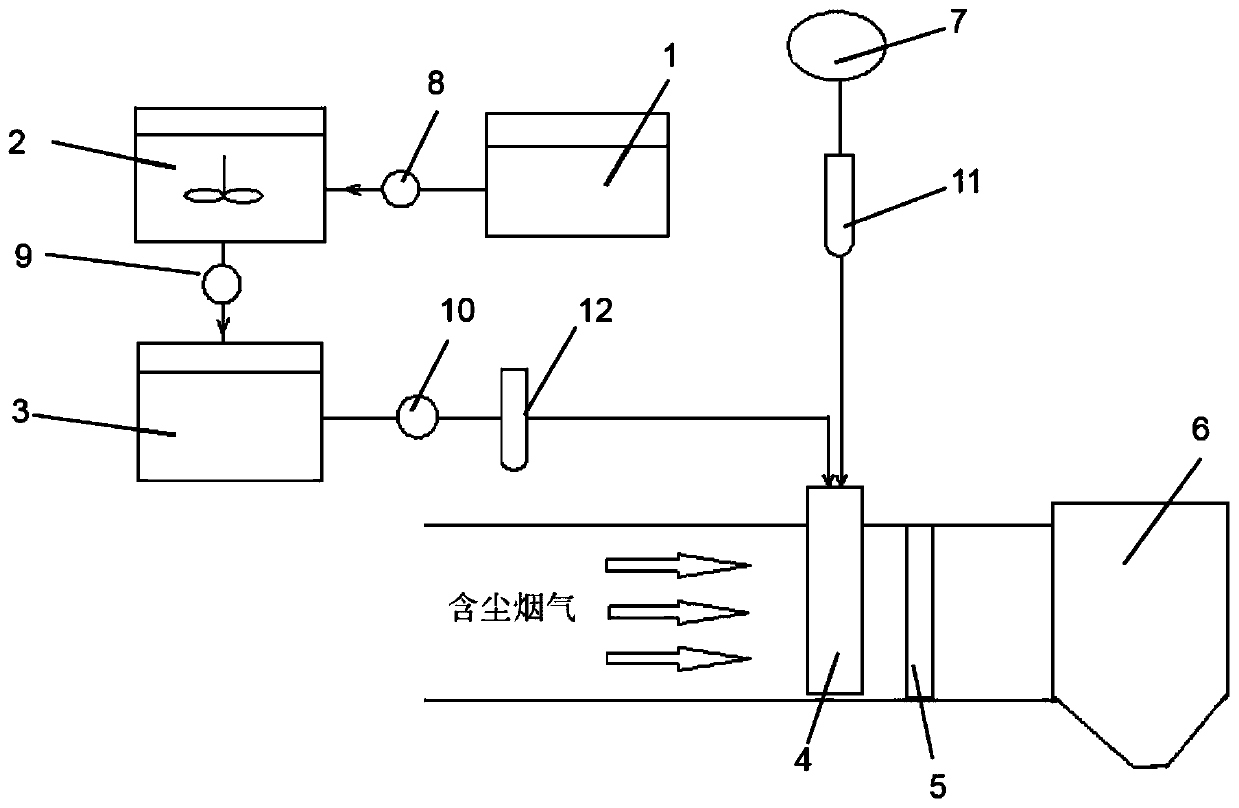

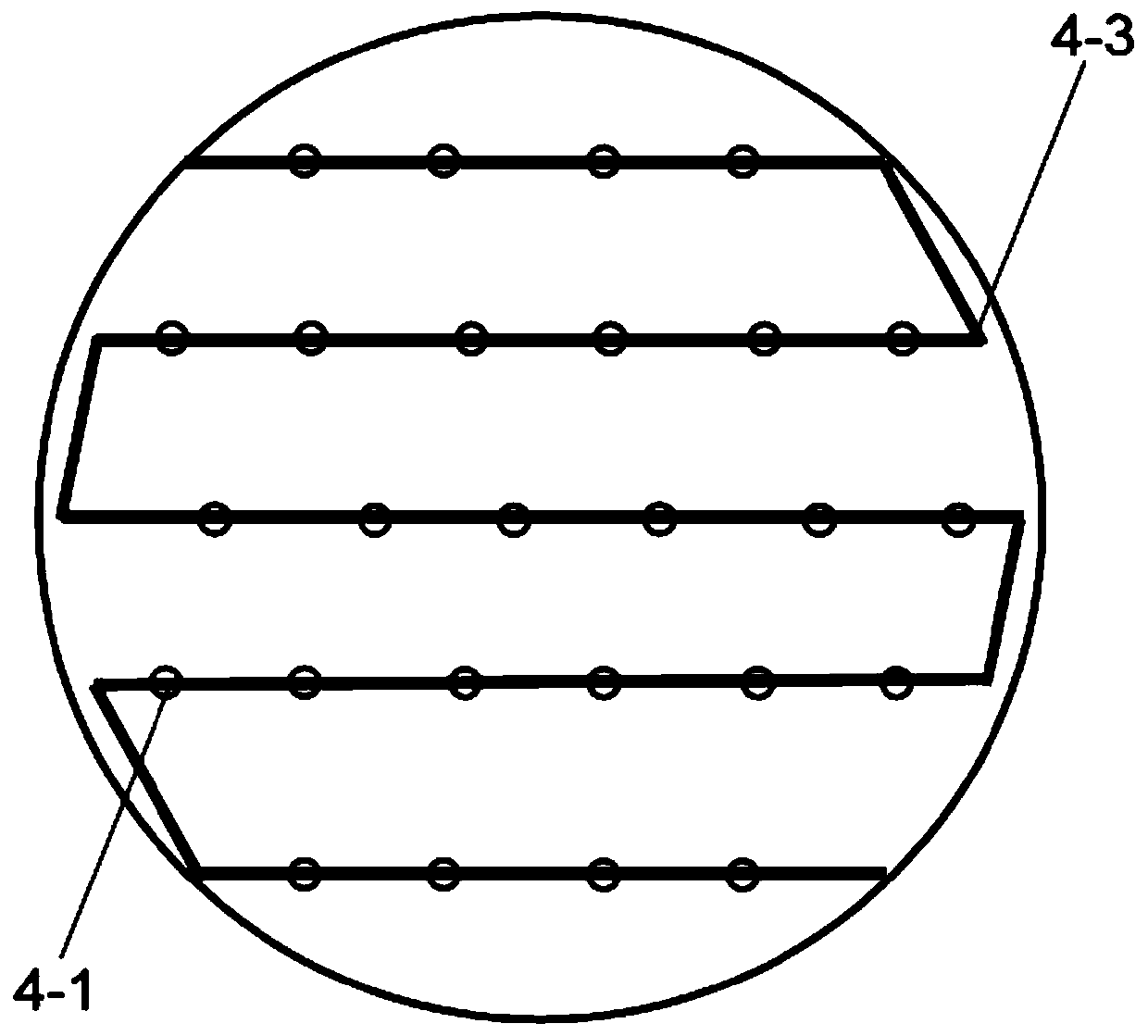

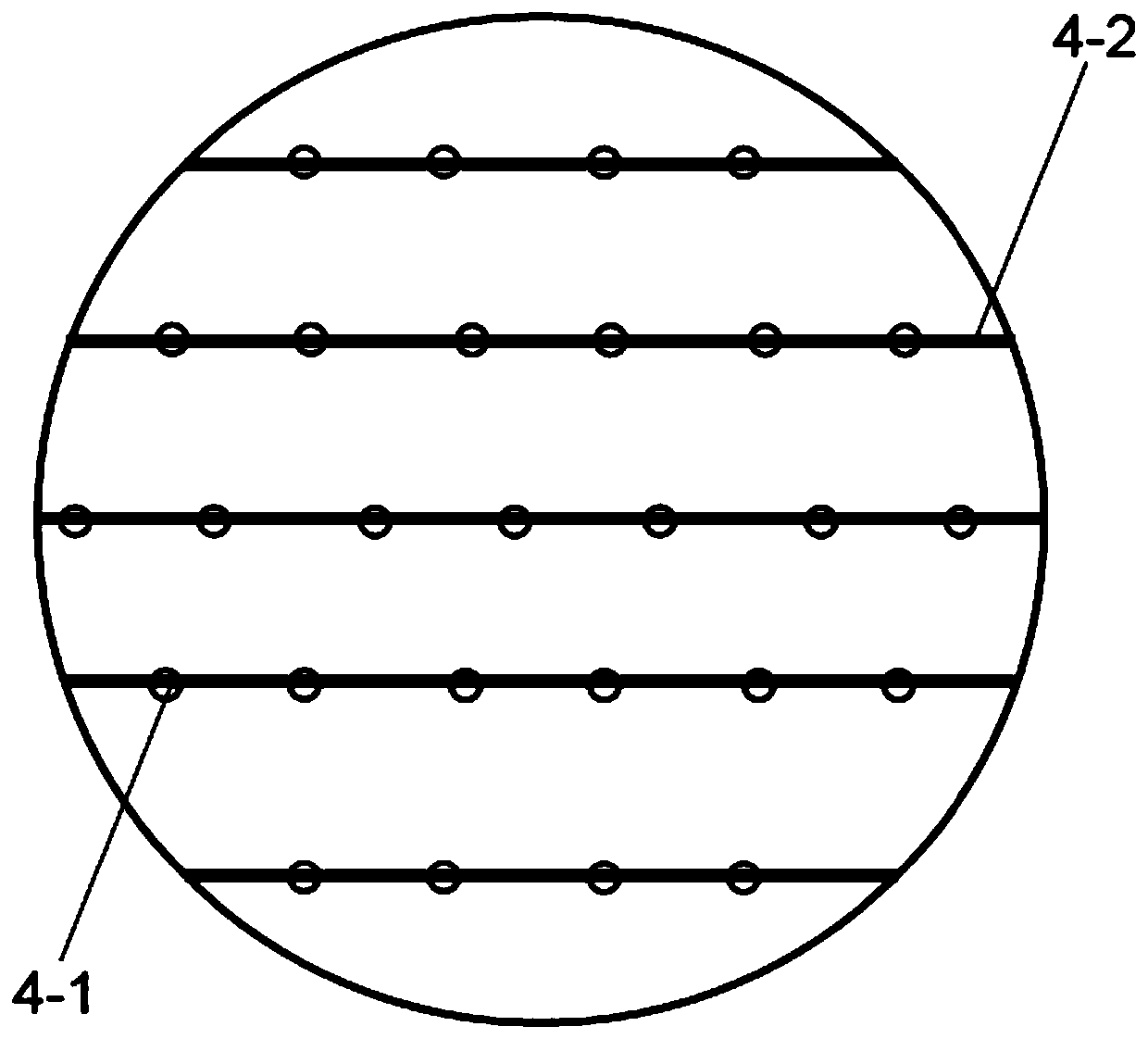

[0053] Such as figure 1 As shown, the present invention provides a device for removing fine particles, including a first liquid storage unit 1, a first mixing unit 2, a second liquid storage unit 3, an atomization unit 4, a second mixing unit 5, and dust removal Unit 6; the dust removal unit 6 can be a wet electrostatic precipitator; the second mixing unit 5 can be an electrostatic mixer.

[0054] The first liquid storage unit 1, the first mixing unit 2 and the second liquid storage unit 3 are sequentially connected, so that the solvent from the first liquid storage unit 1 enters the first mixing unit 2 and mixes with the chemical raw materials therein to form a chemical After the agglomeration liquid enters the second liquid storage unit 3;

[0055] The second liquid storage unit 3, the atomization unit 4, and the dust removal unit 6 are sequentially connected, so that the chemical agglomeration liquid from the second liquid storage unit 3 is atomized by the atomization unit 4, an...

Embodiment 2

[0070] This embodiment provides a chemical agglomeration liquid, which is prepared by the following method: 0.08g glycerol, 0.05g cellulose, 0.02g sesame gum and 99.85g water are sequentially added to the mixing unit, and then slowly added to the mass concentration Adjust the pH value to 6.5 with 1 wt% phosphoric acid aqueous solution to prepare a chemical agglomeration liquid.

[0071] This embodiment also provides an application of the above chemical agglomeration liquid in the removal of fine particles: the chemical agglomeration liquid is sent to the atomization unit by a metering pump, and is atomized into a particle with an average particle size of about 30 μm under the action of pressurized air The mist is sprayed into the flue, the spraying amount is 2.5g / m 3 ; After mixing with the flue gas, it enters the wet electrostatic precipitator, and then is captured and removed.

Embodiment 3

[0073] This embodiment provides a chemical agglomeration solution, which is prepared by the following method: 0.08g glycerol, 0.05g cellulose, 0.02g sesame gum, 0.005g calcium chloride and 99.85g water are added to the above-mentioned mass in sequence In the mixing unit, a phosphoric acid aqueous solution with a mass concentration of 1 wt% is slowly added to adjust the pH to 6.5 to prepare a chemical agglomeration liquid.

[0074] This embodiment also provides an application of the above chemical agglomeration liquid in the removal of fine particles: the chemical agglomeration liquid is sent to the atomization unit by a metering pump, and is atomized into a particle with an average particle size of about 30 μm under the action of pressurized air The mist is sprayed into the flue, the spraying amount is 2.5g / m 3 ; After mixing with the flue gas, it enters the wet electrostatic precipitator, and then is captured and removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com