Micro-nano ceramic-tube-beam water-film type integrated removal apparatus for flue gas pollutants

A technology of micro-nano and pollutants, applied in chemical instruments and methods, using liquid separation agents, and separation of dispersed particles, etc., can solve the problems of fine particles polluting the atmospheric environment, "white smoke" from the chimneys of thermal power plants, and wasting precious water resources , to achieve significant emission reduction effects, long service life, and obvious water-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

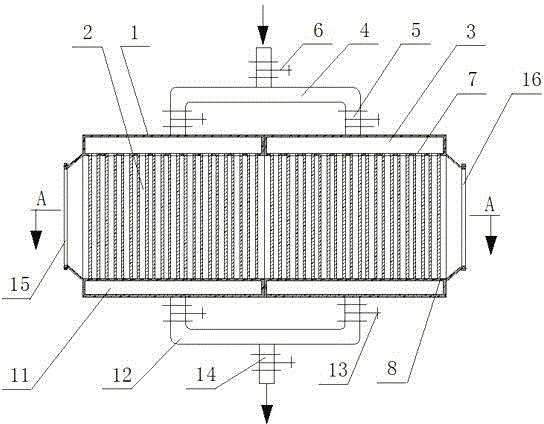

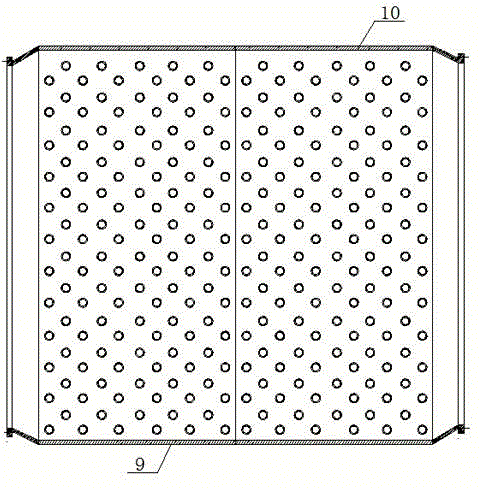

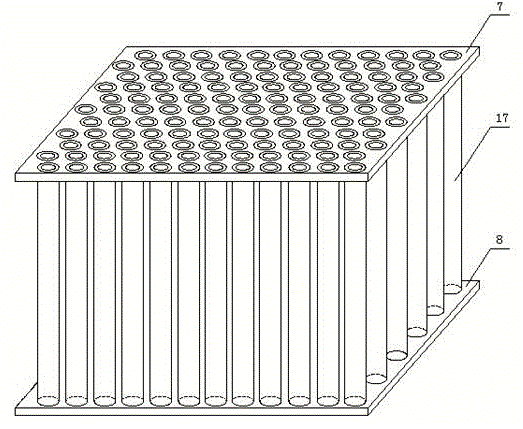

[0025] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described as follows:

[0026] When using the present invention, at first the described hollow porous micro-nano ceramic tube bundle water film type flue gas pollutant integrated removal device is installed in the flue after the desulfurization device, and the flue gas inlet is connected to the flange (15) and the side of the desulfurization device. The flue is connected, the flue gas outlet connecting flange (16) is connected with the flue on the chimney side, the water inlet pipe (4) is connected with the water supply source, and the sewage discharge pipe (12) is connected with the sewage treatment system of the power plant.

[0027] When working, firstly open the water inlet flow control valve (5) and the main water inlet valve (6) in the water inlet chamber. Keep between 0.2-0.3MPa, and ensure that the pressure inside the tube of each hollow porous micro-nano ceramic tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com