Beneficiation method for strengthened recycling of fine-particle chromite

A beneficiation method and chromite technology, which is applied in the field of beneficiation to strengthen the recovery of fine-grained chromite, can solve the problems of difficult recovery of fine-grained chromite, achieve good emission reduction effects, improve resource utilization, and avoid tailings Difficulty settling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

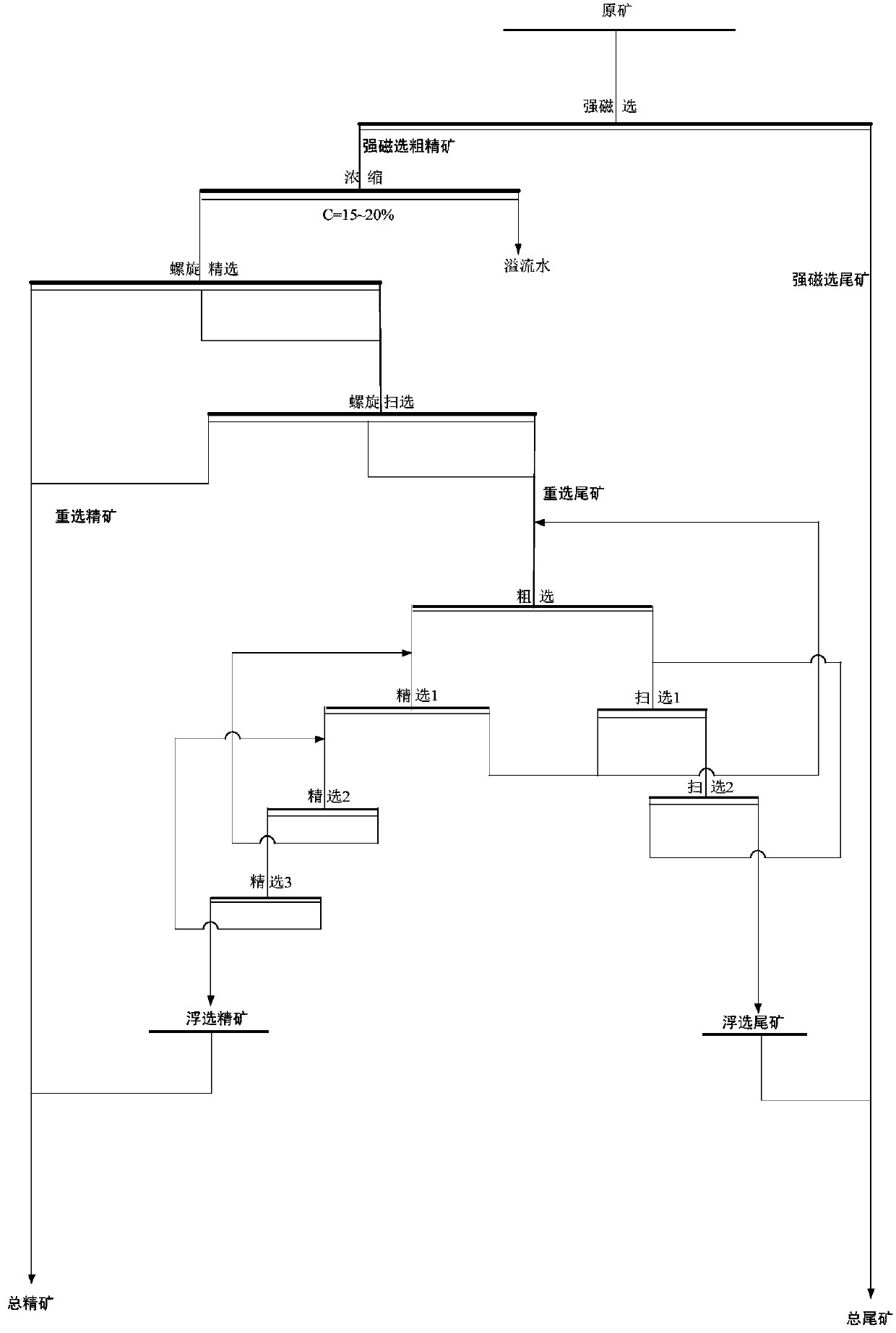

[0035] This embodiment provides a kind of beneficiation method that strengthens recovery fine-grained chromite ore, and flow process is as follows figure 1 As shown, the specific steps are as follows:

[0036] S1. Select chrome ore from a certain place in South Africa. The main mineral composition is chromite, enstatite, anorthite, tremolite, diopside, quartz, albite, etc. Raw Cr 2 o 3 The grade is 19.68%, and the fineness -0.074mm accounts for 72.85% (-0.043mm accounts for 50.81%). Raw ore is subjected to high-gradient wet magnetic separation under the background magnetic field of 0.9T to obtain strong magnetic separation rough concentrate and strong magnetic separation tailings.

[0037] S2. adjust the pulp mass concentration of strong magnetic separation coarse concentrate to be 15%, adopt Cubic parabolic spiral chute, yield 24.34% after one rough and one sweep, Cr 2 o 3 Gravity separation concentrate and gravity separation tailings with a grade of 42.11% and a recov...

Embodiment 2

[0041] This embodiment provides a kind of beneficiation method that strengthens recovery fine-grained chromite ore, and flow process is as follows figure 1 As shown, the specific steps are as follows:

[0042] S1. Select chromium ore from a certain place in South Africa. The main minerals are chromite, enstatite, anorthite, tremolite, diopside, albite, biotite, etc. Raw Cr 2 o 3 The grade is 22.21%, and the fineness -0.074mm accounts for 50.54% (-0.043mm accounts for 31.07%). Raw ore is subjected to high-gradient wet magnetic separation under the background magnetic field of 0.9T to obtain strong magnetic separation rough concentrate and strong magnetic separation tailings.

[0043] S2. adjust the pulp mass concentration of strong magnetic separation coarse concentrate to be 18%, adopt Cubic parabolic spiral chute, yield 34.75% after one rough and one sweep, Cr 2 o 3 Gravity separation concentrate and gravity separation tailings with a grade of 42.15% and a recovery rat...

Embodiment 3

[0047] This embodiment provides a kind of beneficiation method that strengthens recovery fine-grained chromite ore, and flow process is as follows figure 1 As shown, the specific steps are as follows:

[0048] S1. Select chromium ore from a certain place in South Africa. The main minerals are chromite, enstatite, anorthite, tremolite, diopside, albite, biotite, etc. Raw Cr 2 o 3 The grade is 18.51%, and the fineness -0.074mm accounts for 86.77% (-0.043mm accounts for 70.87%). Raw ore is subjected to high-gradient wet magnetic separation under a background magnetic field of 1.0T to obtain strong magnetic separation coarse concentrate and strong magnetic separation tailings.

[0049] S2. adjust the pulp mass concentration of strong magnetic separation coarse concentrate to be 15%, adopt Cubic parabolic spiral chute, yield 4.06% after one rough and one sweep, Cr 2 o 3 Gravity separation concentrate and gravity separation tailings with a grade of 42.64% and a recovery rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com