Hot air and exhaust gas double-medium powder delivery method and exhaust gas and hot air mixer

A mixer and dual-media technology, applied in the field of coal-fired boilers, can solve the problems of high NOx emissions, poor boiler combustion stability, and wear of the inlet valve of the primary air duct, and achieve the effects of reducing NOx emissions, alleviating wear and reducing emissions. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

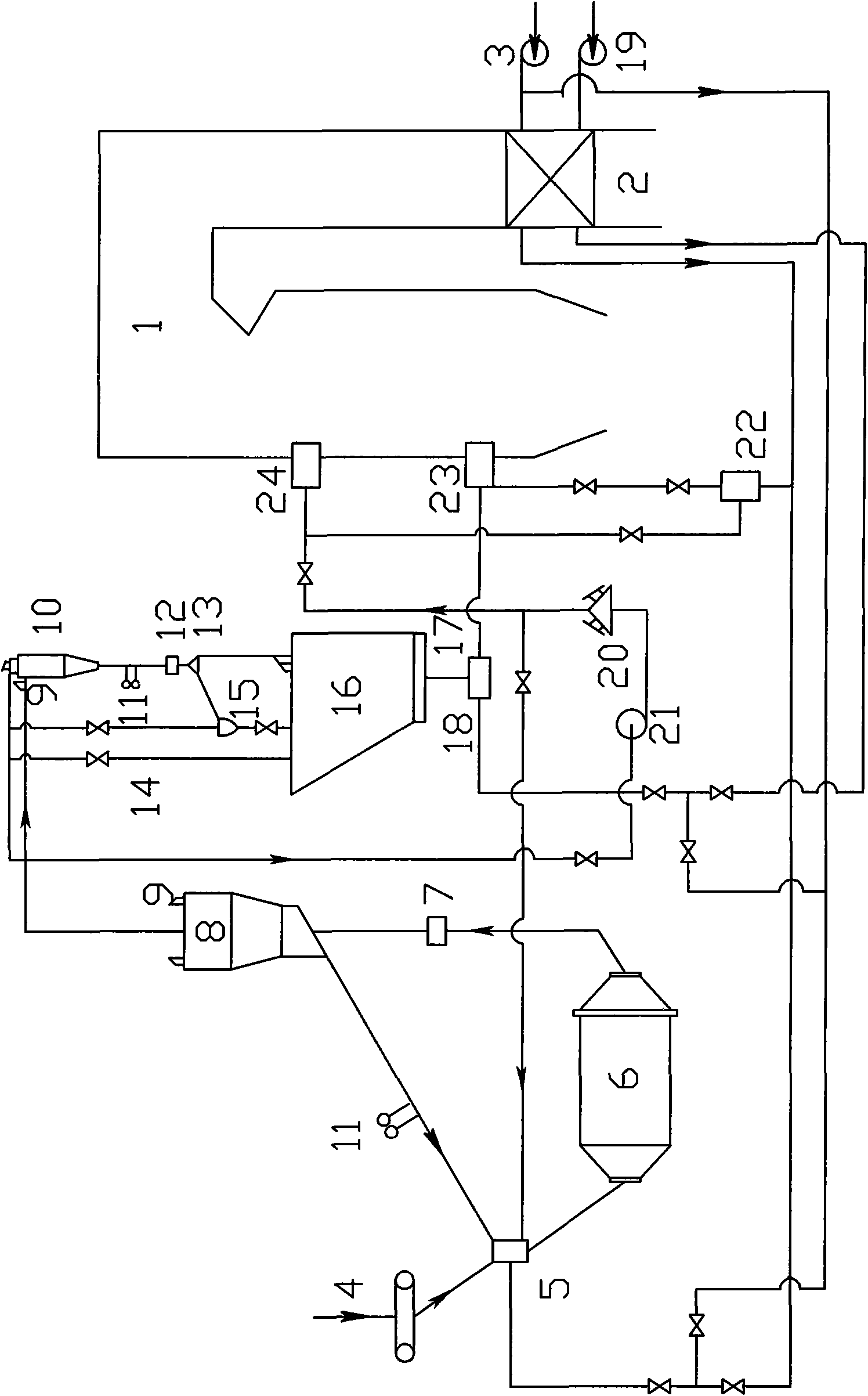

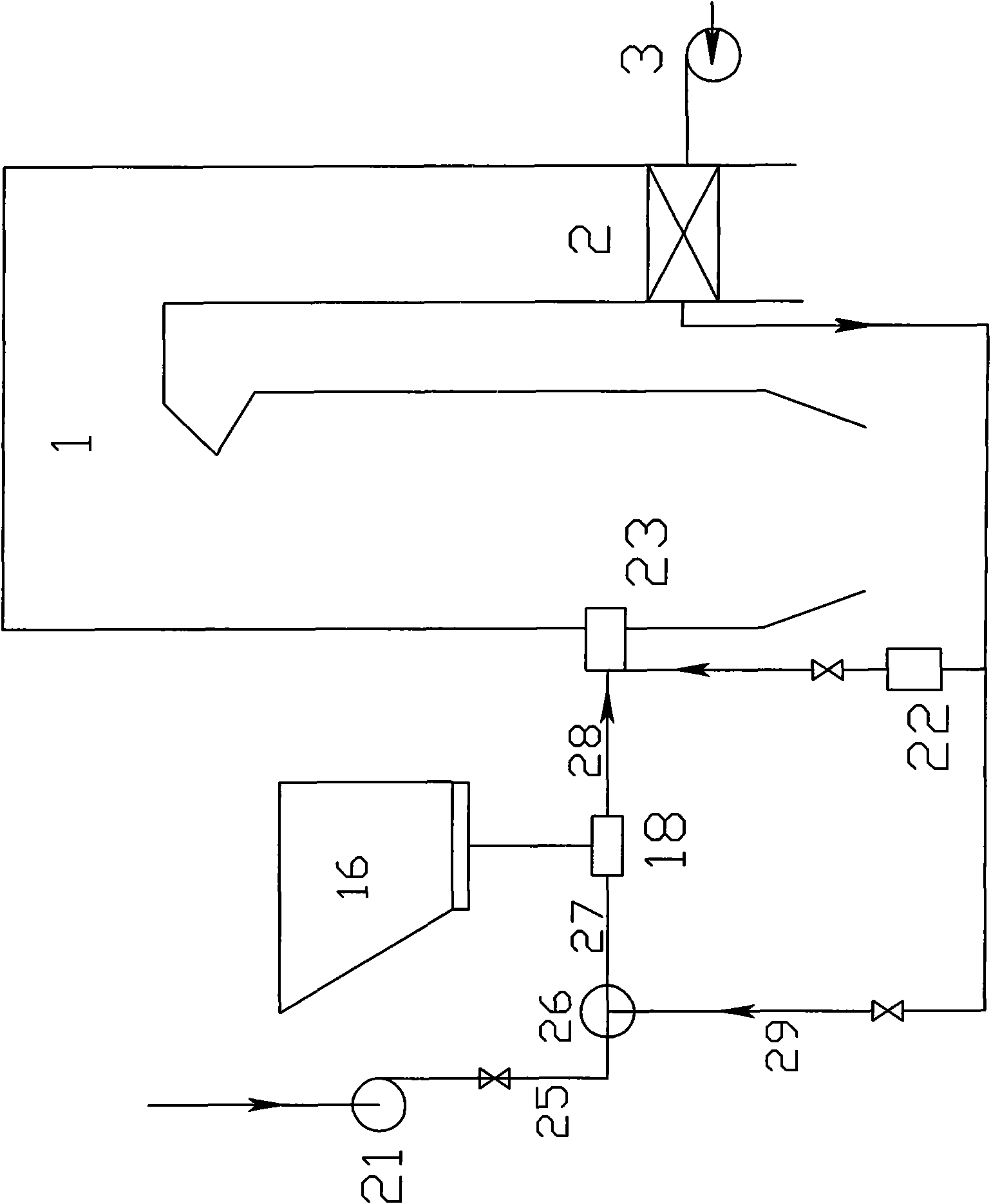

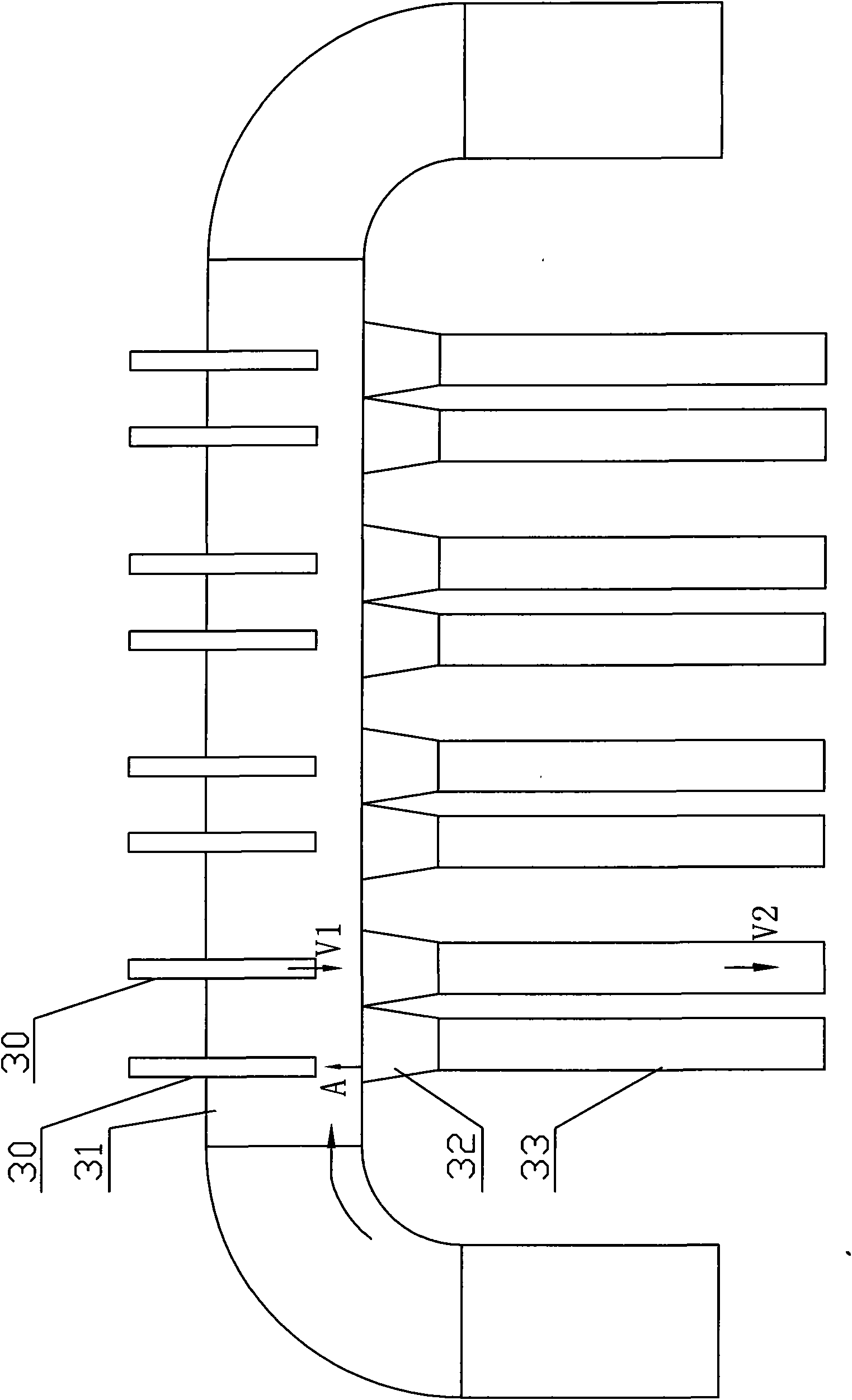

[0017] Specific implementation mode one: see figure 2 and image 3 , the hot air and exhaust air dual-medium powder feeding method described in this embodiment is: use the exhaust air hot air mixer 26 to connect the exhaust air pipeline 25 and the hot air pipeline 29, and send the exhaust air from the exhaust air pipeline 25 to the hot air pipeline 29. The hot air mixed with it is used as the primary air for powder delivery; the velocity V1 of the exhaust air coming out from the exhaust air nozzle 30 of the exhaust air hot air mixer is controlled to be 30-100m / s; the velocity V2 after the exhaust air and hot air are mixed is controlled It is 25-50m / s. The exhaust air hot air mixer not only realizes the full mixing of exhaust air and hot air, but also can effectively match the pressure of the exhaust air pipeline and the hot air pipeline to improve the combustion stability of the boiler.

specific Embodiment approach 2

[0018] Specific Embodiment 2: In this embodiment, the velocity V1 of the exhaust gas coming out of the exhaust gas nozzle 30 of the exhaust air hot air mixer is controlled to be 40-50 m / s. Effectively matches the resistance of the exhaust pipe, and the mixing effect of exhaust air and hot air is better. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific Embodiment Three: In this embodiment, the speed V1 at which the exhaust air comes out from the exhaust air nozzle 30 of the exhaust air hot air mixer is controlled to be 45 m / s. Effectively matches the resistance of the exhaust pipe, and the mixing effect of exhaust air and hot air is better. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com