Cooperative treatment technology for copper-containing electronic wastes

An electronic waste and co-processing technology, applied in combustion methods, lighting and heating equipment, combustion types, etc., can solve the problems of high noise and dust, difficult to deal with wastes such as electronic components, labor and energy, etc. Efficient recycling, obvious effect of emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with examples.

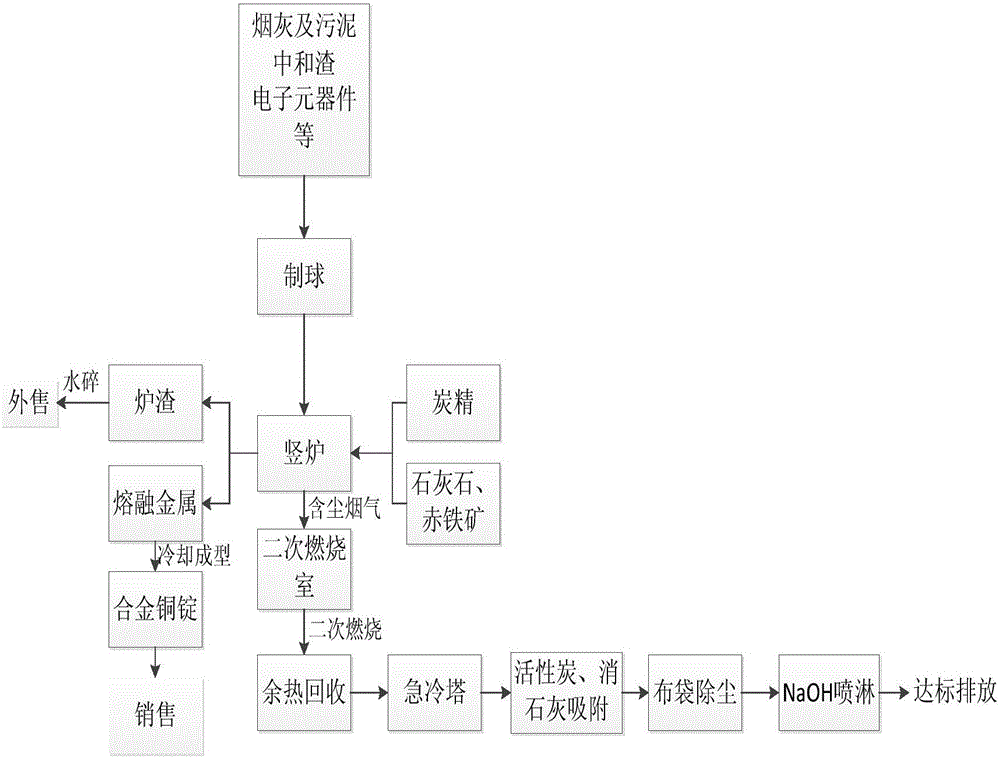

[0025] A cooperating process for copper-containing electronic waste, comprising the steps of:

[0026] 1) Raw materials such as soot, sludge, neutralization slag, and electronic components are piled up in the raw material yard after entering the factory. After the bulk materials are crushed, various waste mixtures are prepared according to the assay content of the relevant metals in the waste, and are carried out in the mixing yard. Stir, mix, and send to the ball making machine to make balls;

[0027] 2) The pellets produced by the pelletizing machine and auxiliary materials such as carbon concentrate, limestone, and hematite are sent to the shaft furnace for combustion, and the relevant materials descend under the action of their own weight, and pass through the preheati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com