Process for preparing dissolved pulp by oxidative decomposition of paper pulp

A technology for dissolving pulp and paper pulp, which is applied in the fields of spinning solution preparation, textile and papermaking, pulping with inorganic alkali, etc. It can solve the problems of resource shortage, low yield, long cycle, etc., to improve the pulping yield and reduce the Pollution, the effect of shortening the pulping cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] a. The sample is wood pulp, dry weight 1Kg

[0024] b. Cold alkali impregnation, impregnation alkali concentration: 87g / l

[0025] c. Dipping pulp concentration: 5%

[0026] d. Amount of additives added: 0.2%

[0027] e. Dipping time: 8 minutes

[0028] f. Dehydration with a dehydrator after immersion

[0029] g. Squeeze to adjust the bath ratio to 1:3

[0030] h. Oxygenation oxygen pressure is 0.5Mpa

[0031] i. Oxygen decomposition oxygen pressure is 0.5Mpa

[0032] j. Oxygen decomposition temperature is 48°C

[0033] k, oxygen decomposition time is 100 minutes.

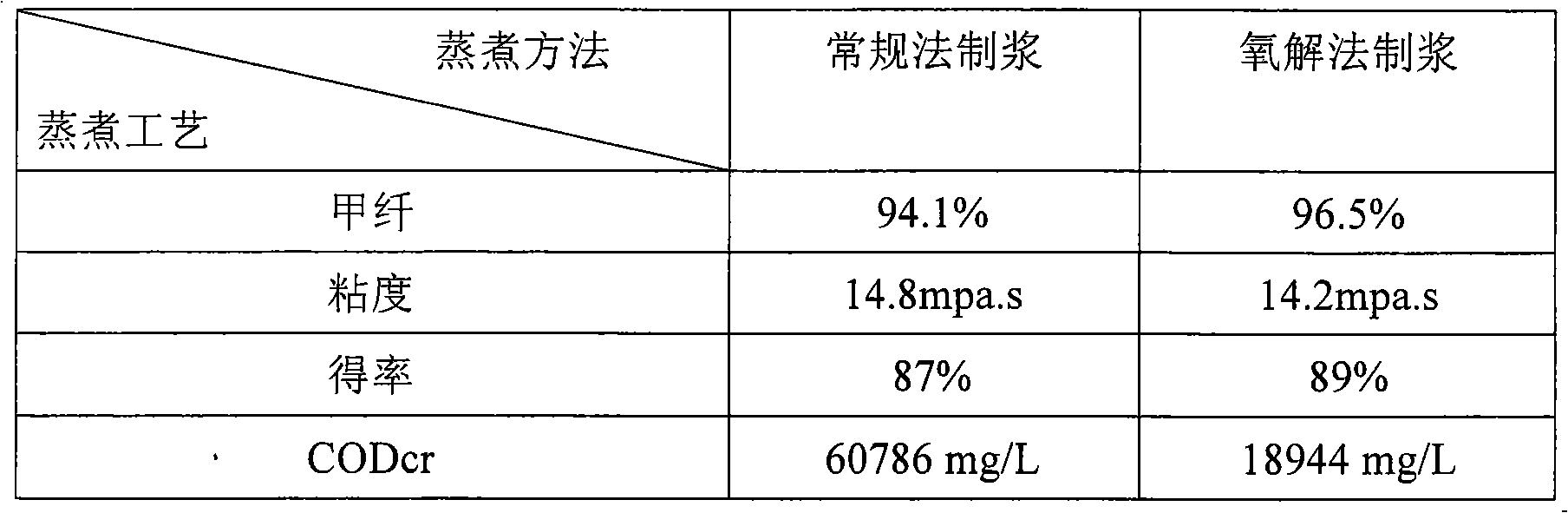

[0034] This embodiment compares with conventional method:

[0035]

Embodiment 2

[0037] a. The sample is bamboo pulp, dry weight 1Kg

[0038] b. Cold alkali impregnation, impregnation alkali concentration: 87g / l

[0039] c. Dipping pulp concentration: 5%

[0040] d. Amount of additives added: 0.2%

[0041] e. Dipping time: 8 minutes

[0042] f. Dehydration with a dehydrator after immersion

[0043] g. Squeeze to adjust the bath ratio to 1:3

[0044] h. Oxygenation oxygen pressure is 0.5Mpa

[0045] i. Oxygen decomposition oxygen pressure is 0.5Mpa

[0046] j. Oxygen decomposition temperature is 50°C

[0047] k, oxygen decomposition time is 60 minutes.

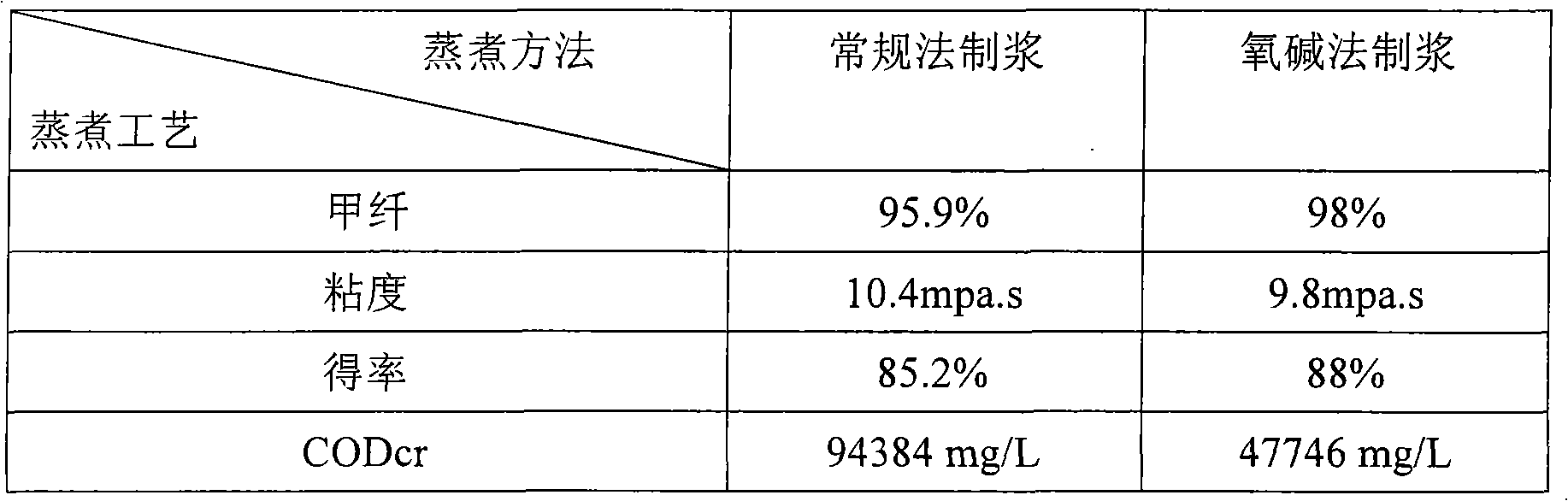

[0048] This embodiment compares with conventional method:

[0049]

Embodiment 3

[0051] a. The sample is wood pulp, dry weight 1Kg

[0052] b. Cold alkali impregnation, impregnation alkali concentration: 110g / l

[0053] c. Dipping pulp concentration: 5%

[0054] d. Amount of additives added: 0.2%

[0055] e. Dipping time: 30 minutes

[0056] f. Dehydration with a dehydrator after immersion

[0057] g. Squeeze to adjust the bath ratio to 1:4

[0058] h. Oxygenation oxygen pressure is 0.4Mpa

[0059] i. Oxygen decomposition oxygen pressure is 0.4Mpa

[0060] j. Oxygen decomposition temperature is 65°C

[0061] k, oxygen decomposition time is 40 minutes.

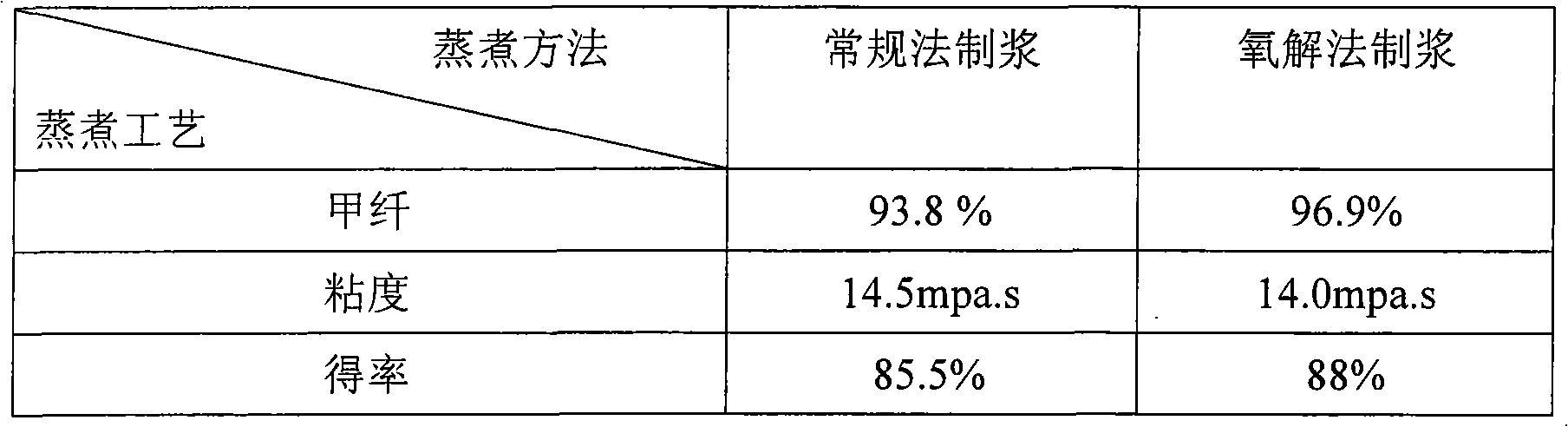

[0062] This embodiment compares with conventional method:

[0063]

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com