Energy-saving device and method for producing hard carbon black

A technology of hard carbon black and energy-saving devices, which is applied in the direction of combustion methods, indirect carbon dioxide emission reduction, sustainable manufacturing/processing, etc. Mention issues such as oxygen-enriched combustion of exhaust gas to achieve the effect of reducing emissions, ensuring safety and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

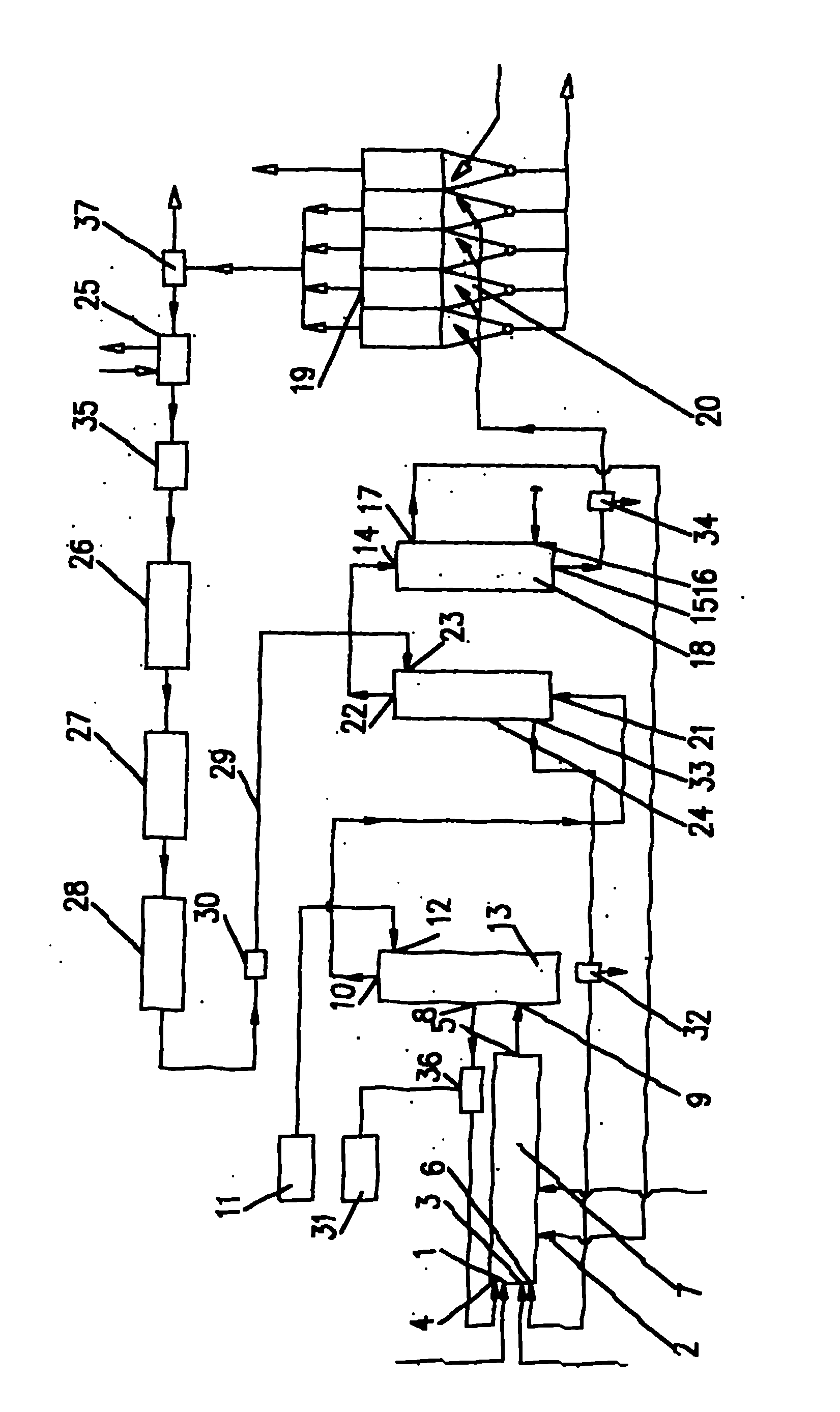

[0023] see figure 1 , the present embodiment hard carbon black production energy-saving device, comprises fuel oil import 1, the first raw material oil import 2, additive import 3, high-temperature oxygen-enriched air import 4, high-temperature flue gas outlet 5, the charcoal of preheating exhaust gas import 6 The black reaction furnace 7 has a high-temperature air outlet 8 communicating with the carbon black reaction furnace high-temperature oxygen-enriched air inlet and a high-temperature flue gas outlet, a high-temperature first flue gas inlet 9 and a first flue gas outlet 10, and a main blower fan 11. The high-temperature air preheater 13 of the air inlet 12, the oxygen-enriched mixer 36 communicated with the high-temperature air outlet 8, the high-temperature oxygen-enriched inlet, and the oxygen generator 31 have a third flue gas inlet 14, a third flue gas outlet 15, a third flue gas The second raw material oil inlet 16 and the raw material oil preheater 18 of the first ...

Embodiment 2

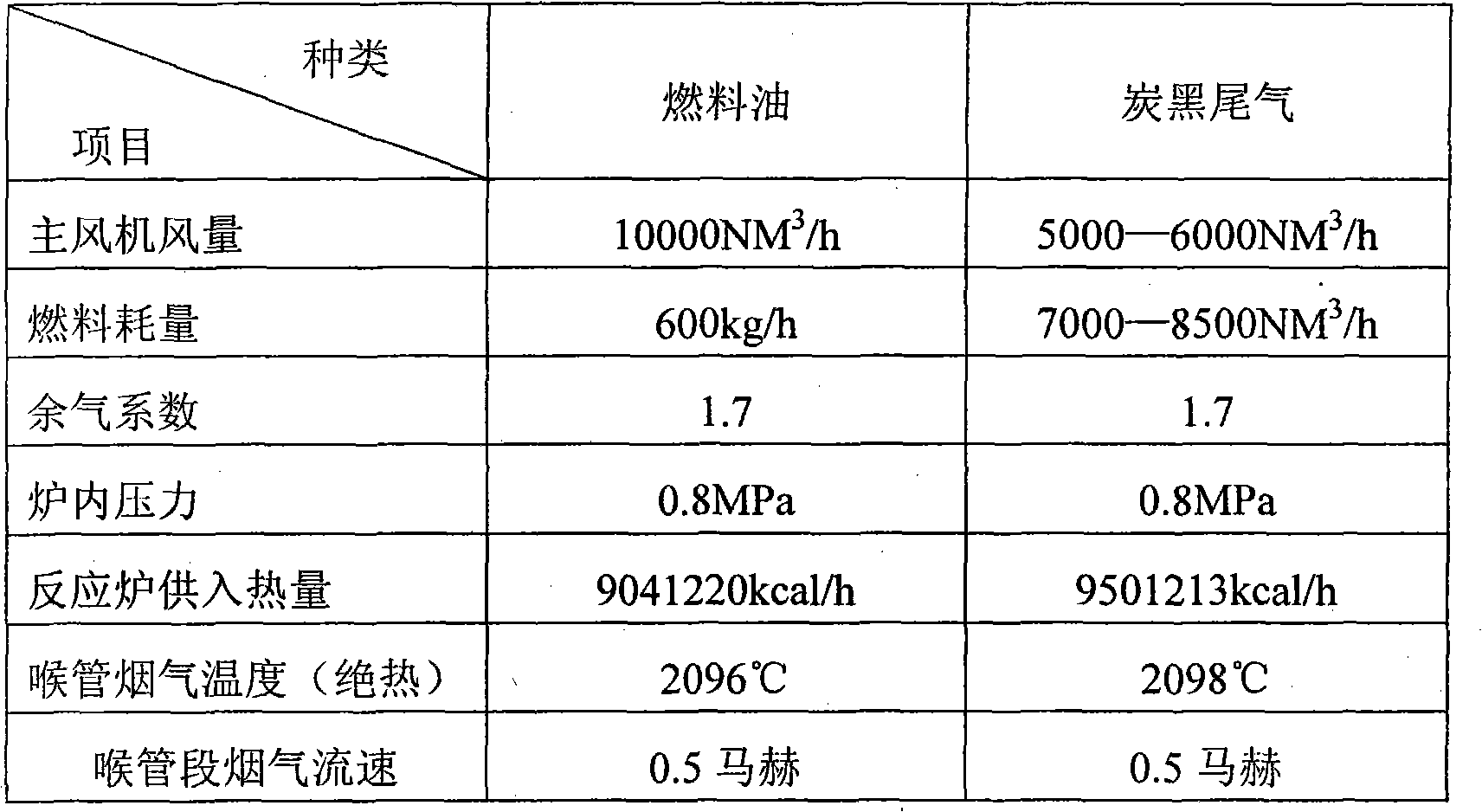

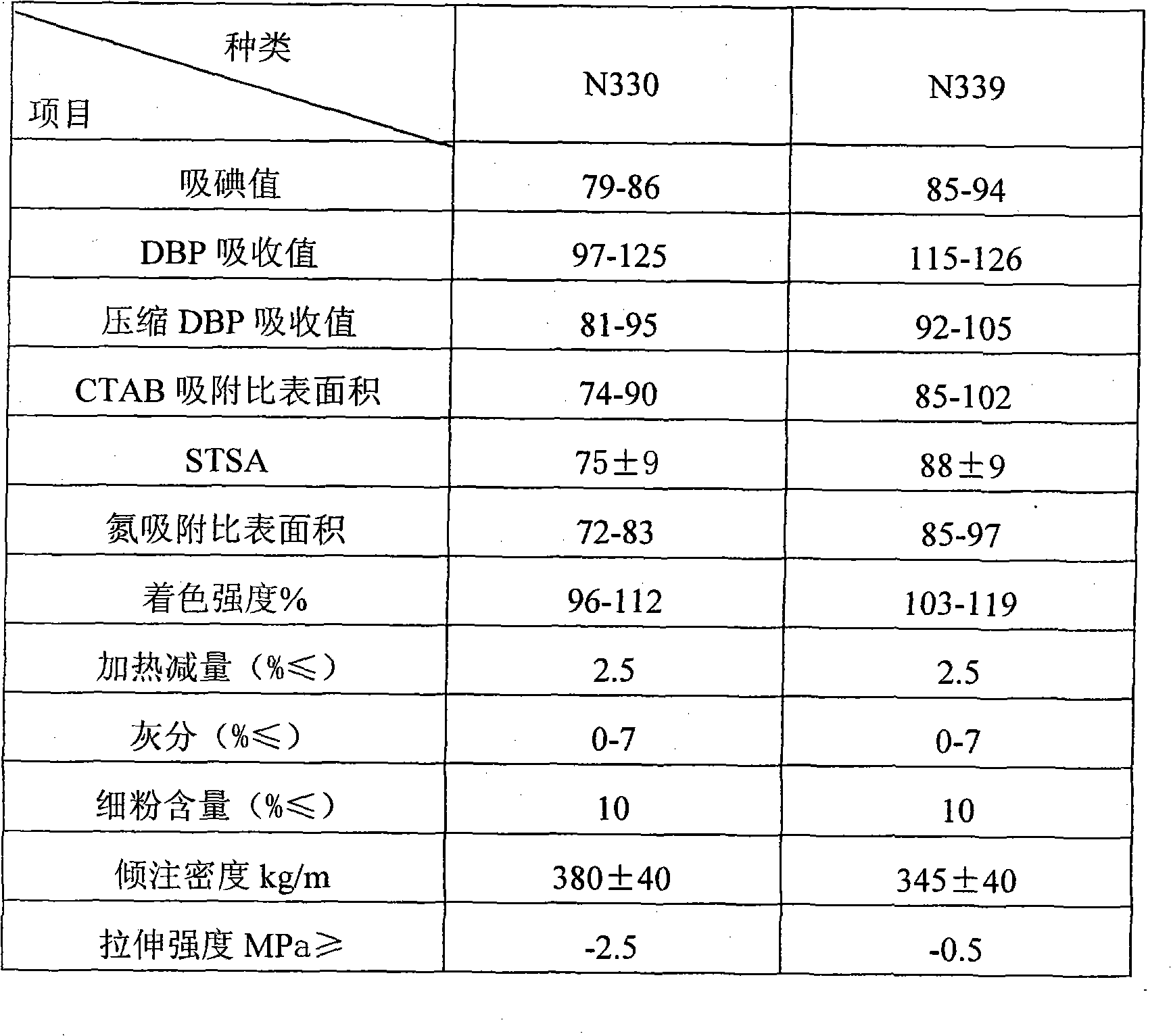

[0032] By the device of embodiment 1, take the hard carbon black production line with an annual output of 20,000 tons as example.

[0033] The production method of hard carbon black production energy-saving comprises the following steps:

[0034] Take the hard carbon black production line with an annual output of 20,000 tons as an example:

[0035] 1. Open the three-way valves 32 and 34 to the empty state.

[0036] 2. Start the fuel oil and gas system to supply fuel oil and gas to ignite the oven and preheat it. When the oven temperature rises to the temperature of raw material oil, the raw material oil supply system starts to supply raw material oil to the hard carbon black reaction furnace through the raw material oil inlet, closes the three-way valve 34, and starts production.

[0037] 3. The hard carbon black reaction furnace 7 produces carbon black flue gas, and the flue gas quenched to 950° C. by the quenching water for terminating the reaction is passed into the high-...

Embodiment 3

[0040] By the device of embodiment 1, take the hard carbon black production line with an annual output of 20,000 tons as example.

[0041] The production method of hard carbon black production energy-saving comprises the following steps:

[0042] Take the hard carbon black production line with an annual output of 20,000 tons as an example:

[0043] 1. Open the three-way valves 32 and 34 to the empty state.

[0044] 2. Start the fuel oil and gas system to supply fuel oil and gas to ignite the oven and preheat it. When the oven temperature rises to the temperature of raw material oil, the raw material oil supply system starts to supply raw material oil to the hard carbon black reaction furnace through the raw material oil inlet, closes the three-way valve 34, and starts production.

[0045] 3. The hard carbon black reaction furnace 7 produces carbon black flue gas, and the flue gas that is quenched to 980 °C by the quenching water after the reaction is terminated is passed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com