Micro-expansion grouting material and preparation method thereof

A grouting material and micro-expansion technology, applied in the field of building grouting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

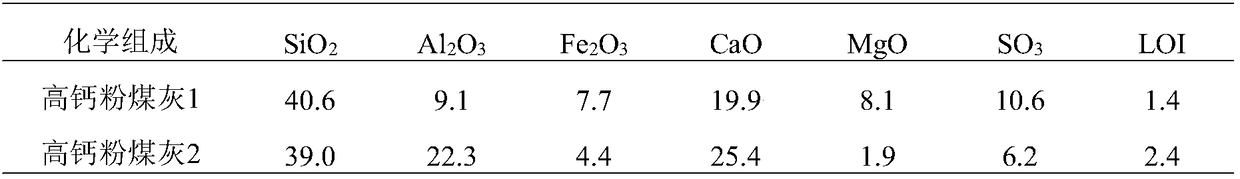

Method used

Image

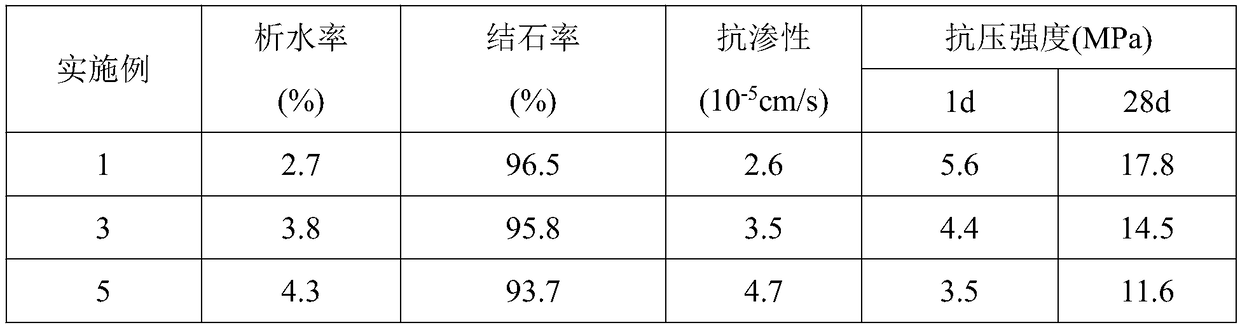

Examples

Embodiment 1

[0065] A kind of micro-expansion grouting material of this embodiment adopts the following mass parts ratio of materials:

[0066] High calcium fly ash: 30 parts

[0067] Calcined shale: 30 parts

[0068] Phosphogypsum: 5 parts

[0069] Ordinary Portland cement: 20 parts

[0070] Rapid hardening sulfoaluminate cement: 15 parts;

[0071] The above-mentioned materials are all powder materials and together form a gelling material. On the basis of the total number of parts of the above-mentioned materials constituting the gelling material being adjusted to 100 parts, and then according to the mass multiple of the total number of parts of the above-mentioned materials, add the following Additive materials and water:

[0072] Polycarboxylate superplasticizer: 0.01 times

[0073] Redispersible latex powder: 0.005 times

[0074] Hydroxypropyl methylcellulose ether: 0.0005 times

[0075] Calcium lignosulfonate: 0.004 times parts

[0076] Cationic organic polymer: 0.001 times part...

Embodiment 2

[0084] A kind of micro-expansion grouting material of this embodiment adopts the following mass parts ratio of materials:

[0085] High calcium fly ash: 40 parts

[0086] Calcined Shale: 25 parts

[0087] Phosphogypsum: 10 parts

[0088] Ordinary Portland cement: 15 parts

[0089] Rapid hardening sulfoaluminate cement: 10 parts;

[0090] The above-mentioned materials are all powder materials and together form a gelling material. On the basis of the total number of parts of the above-mentioned materials constituting the gelling material being adjusted to 100 parts, and then according to the mass multiple of the total number of parts of the above-mentioned materials, add the following Additive materials and water:

[0091] Polycarboxylate superplasticizer: 0.008 times

[0092] Redispersible latex powder: 0.002 times

[0093] Hydroxypropyl methylcellulose ether: 0.0005 times

[0094] Calcium lignosulfonate: 0.003 times parts

[0095] Cationic organic polymer: 0.002 times ...

Embodiment 3

[0099] A kind of micro-expansion grouting material of this embodiment adopts the following mass parts ratio of materials:

[0100] High calcium fly ash: 40 parts

[0101] Calcined shale: 20 parts

[0102] Phosphogypsum: 10 parts

[0103] Ordinary Portland cement: 15 parts

[0104] Rapid hardening sulfoaluminate cement: 15 parts;

[0105] The above-mentioned materials are all powder materials and together form a gelling material. On the basis of the total number of parts of the above-mentioned materials constituting the gelling material being adjusted to 100 parts, and then according to the mass multiple of the total number of parts of the above-mentioned materials, add the following Additive materials and water:

[0106] Polycarboxylate superplasticizer: 0.008 times

[0107] Redispersible latex powder: 0.006 times

[0108] Hydroxypropyl methyl cellulose ether: 0.0010 times parts

[0109] Calcium lignosulfonate: 0.003 times parts

[0110] Cationic organic polymer: 0.003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com