Phosphoric acid excited magnesium-rich nickel slag geopolymer cementing material and preparation method thereof

A geopolymer, magnesium-nickel-rich slag technology, applied in cement production and other directions, can solve the problems of unstable strength, rapid setting, water pollution, etc., to promote rational utilization and environmental protection, good compressive strength, and reduce raw materials. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

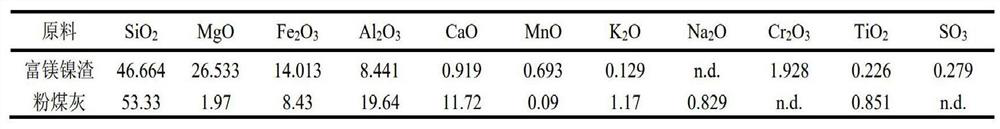

[0019] A phosphoric acid-excited magnesium-nickel slag geopolymer cementitious material and its preparation method, comprising: the content of the main chemical components of the magnesium-rich nickel slag and fly ash raw materials used in the embodiment of the present invention is analyzed by X-ray fluorescence spectroscopy, and the result As shown in Table 1:

[0020] Table 1 Contents of main chemical components of magnesium-rich nickel slag and fly ash raw materials

[0021]

Embodiment 1

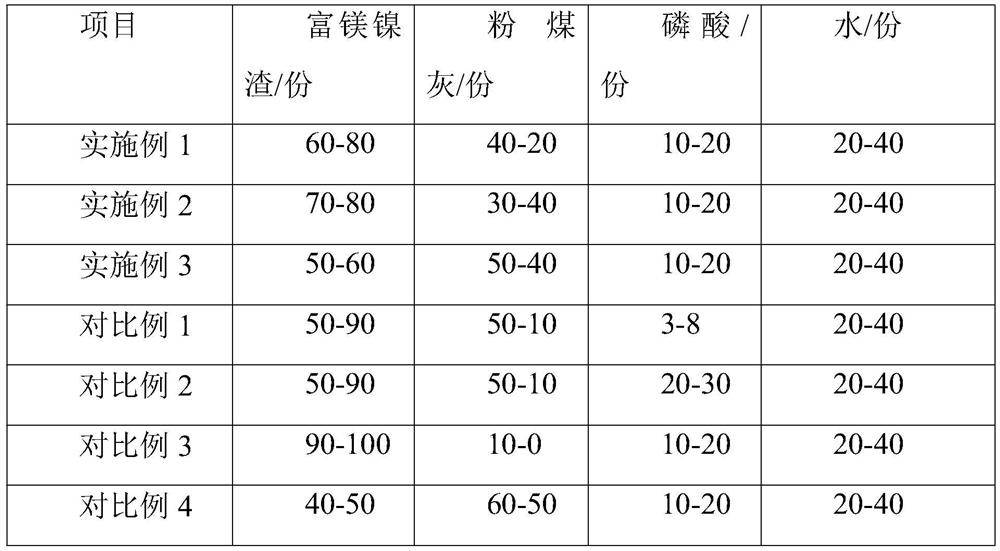

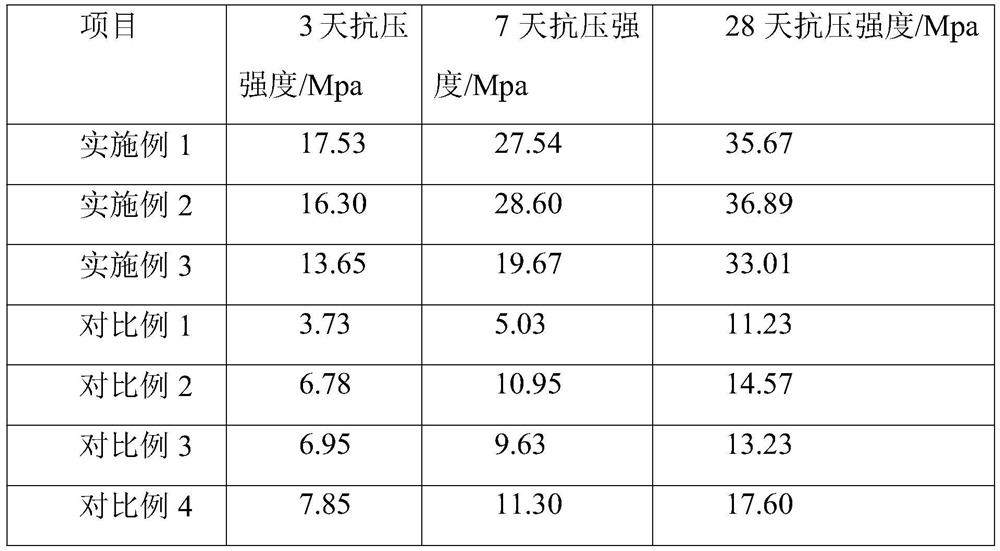

[0023] This embodiment provides a green cementitious material based on magnesium-rich nickel slag and fly ash. 20%, phosphoric acid 10-20% (solid content), deionized water 20-30%.

[0024] The green cementitious material based on magnesium-rich nickel slag and fly ash is obtained through the following steps:

[0025] Powder refinement: put the magnesium-nickel slag and fly ash in an oven, and bake until the quality does not change. After cooling to room temperature, the magnesium-nickel slag is ball-milled with a ball mill, and then passed through a 200-mesh sieve, and the fly ash is directly Pass 200 mesh sieve;

[0026] Prepare acidic liquid: prepare acidic liquid with phosphoric acid and water, set aside after cooling;

[0027] Prepare clean slurry: mix the magnesium-rich nickel slag after the above-mentioned sieving with fly ash, then add acidic liquid, stir evenly, and obtain clean slurry;

[0028] Forming maintenance: After vibration forming, seal the mold poured with...

Embodiment 2

[0031] This embodiment provides a green cementitious material based on magnesium-rich nickel slag and fly ash. 40%, phosphoric acid 10-20% (solid content), deionized water 20-30%.

[0032] The green cementitious material based on magnesium-rich nickel slag and fly ash is obtained through the following steps:

[0033] Powder refinement: put the magnesium-nickel slag and fly ash in an oven, and bake until the quality does not change. After cooling to room temperature, the magnesium-nickel slag is ball-milled with a ball mill, and then passed through a 200-mesh sieve, and the fly ash is directly Pass 200 mesh sieve;

[0034] Prepare acidic liquid: prepare acidic liquid with phosphoric acid and water, set aside after cooling;

[0035] Prepare clean slurry: mix the magnesium-rich nickel slag after the above-mentioned sieving with fly ash, then add acidic liquid, stir evenly, and obtain clean slurry;

[0036] Forming maintenance: After vibration forming, seal the mold poured with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com