Sintering project abandoned soil expanded perlite heat insulation and decoration integral board and preparation method thereof

A technology of expanded perlite and engineering spoils, which is applied in the field of building materials, can solve the problems of affecting the thermal insulation performance of the board, increasing the thermal conductivity, and increasing the cost, and achieves significant economic and social benefits, high solid waste utilization, and saves The effect of decoration construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below.

[0035] A sintering engineering spoil expanded perlite thermal insulation and decoration integrated board, the specific examples are shown in Table 1, Table 2, Table 3 and Table 4.

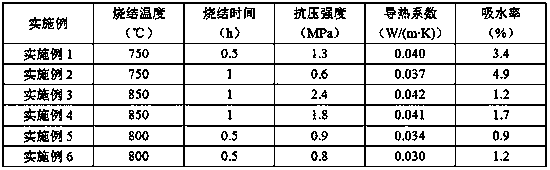

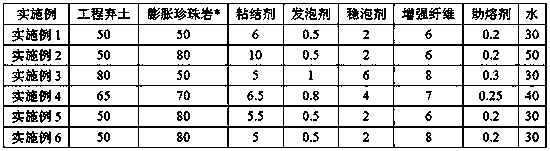

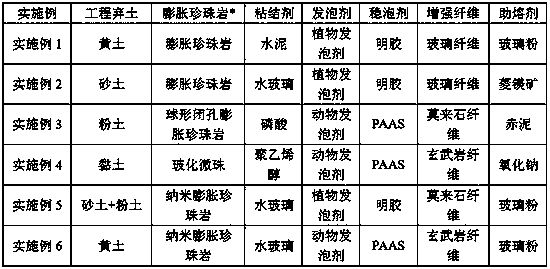

[0036] Table 1 shows the raw materials of the thermal insulation base layer corresponding to each embodiment. Table 2 shows the parts by weight of the raw materials of the thermal insulation base layer corresponding to each embodiment. Table 3 shows the parts by weight of the decorative surface layer raw materials corresponding to each embodiment. Table 4 shows the sintering temperature and sintering time corresponding to each embodiment, as well as the compressive strength and thermal conductivity of the sintering project spoil expanded perlite thermal insulation and decoration integrated board measured by the test.

[0037] The specific steps of the preparation method of the sintering engineering spoil exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com