Method for preparing water-permeable pavement material from construction waste

A technology of permeable pavement and construction waste, applied in the field of comprehensive utilization of solid waste, can solve the problems of low added value of products and limited market capacity, and achieve the effects of improving comprehensive utilization rate, good market prospect and high water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

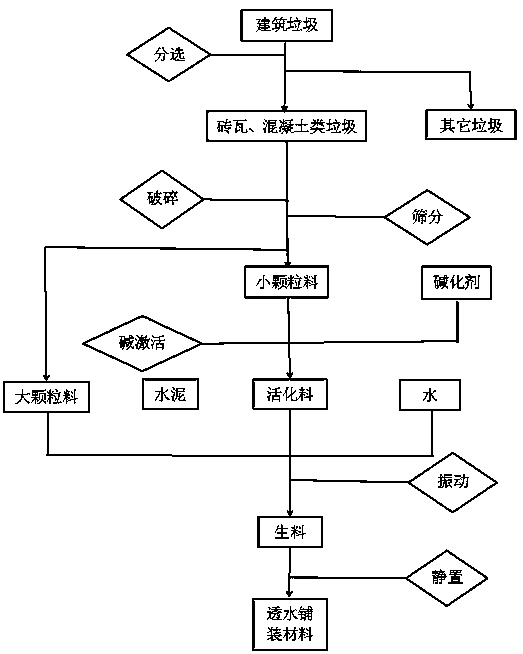

[0031] Include the following steps:

[0032] Step 1. First, sort the construction waste. Use a multi-stage construction waste sorting machine to discharge and collect various materials from multiple outlets to remove plastic, metal and wood in the construction waste, and only keep the bricks. tile, concrete solid waste;

[0033] Step 2. The solid waste is crushed by a crusher, and then screened twice through screens of different specifications. After screening, large particles with a particle size of 1-5 mm and small particles with a particle size of 1 mm or less are obtained;

[0034] Step 3, the small particle material and the alkalizing agent are mixed according to the ratio of 100:5, and then ball milled for 12 hours in a ball mill to obtain the activated material, and the alkalizing agent is sodium hydroxide;

[0035] Step 4, then mix the large particle material, the activation material, the ordinary Portland cement of the label 42.5 and water according to the weight rat...

Embodiment 2

[0039] Include the following steps:

[0040] Step 1. First, sort the construction waste. Use a multi-stage construction waste sorting machine to discharge and collect various materials from multiple outlets to remove plastic, metal and wood in the construction waste, and only keep the bricks. tile, concrete solid waste;

[0041] Step 2. The solid waste is crushed by a crusher, and then screened twice through screens of different specifications. After screening, large particles with a particle size of 1-5mm and small particles with a particle size of less than 1mm are obtained;

[0042] Step 3, the small particle material and the alkalizing agent are mixed according to the ratio of 100:8, and then ball milled for 9 hours to obtain the activated material, and the alkalizing agent is sodium hydroxide and sodium silicate;

[0043] Step 4, then mix the large particle material, the activation material, the ordinary Portland cement of the label 42.5 and water according to the weight...

Embodiment 3

[0047] Include the following steps:

[0048] Step 1. First, sort the construction waste. Use a multi-stage construction waste sorting machine to discharge and collect various materials from multiple outlets to remove plastic, metal and wood in the construction waste, and only keep the bricks. tile, concrete solid waste;

[0049] Step 2. The solid waste is crushed by a crusher, and then screened twice through screens of different specifications. After screening, large particles with a particle size of 1-5 mm and small particles with a particle size of 1 mm or less are obtained;

[0050] Step 3, the small particle material and the alkalizing agent are mixed according to the ratio of 100:10, and then ball milled for 6 hours in a ball mill to obtain the activated material. The alkalizing agent is sodium hydroxide and sodium silicate;

[0051] Step 4, then mix the large particle material, the activation material, the ordinary Portland cement of the label 52.5 and water according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com