Drying method for evaporative crystallization liquid of vanadium precipitation wastewater and method for recovering sodium sulfide

A technology for evaporative crystallization and precipitation of vanadium wastewater, applied in chemical instruments and methods, alkali metal sulfides/polysulfides, water pollutants, etc., can solve the problems of low efficiency of drying evaporation liquid, poor purity of sodium sulfide, etc., and achieve drying The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

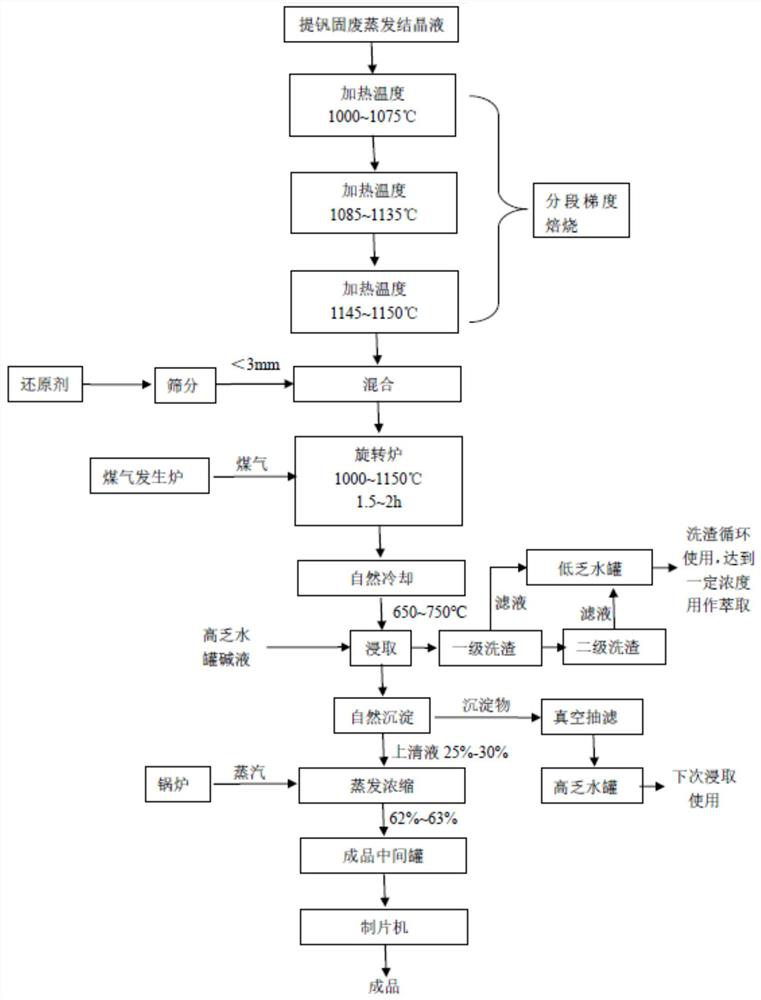

[0055] a. Take 1kg of vanadium precipitation wastewater evaporating crystallization solution, and evaporate the vanadium precipitation wastewater evaporating crystallization solution by segmented heating. The process of segmented heating is: first heat at 1050°C for 0.25h; then heat at 1100°C for 0.5h ; Finally heated at 1150 ℃ for 0.75h. After evaporating, the water content of vanadium precipitation wastewater evaporating crystallization solution is 4.7%;

[0056] b. Pulverize the pulverized coal until the particle size is less than 3mm;

[0057] c. Mix the dried raw material and pulverized coal in a weight ratio of 250:51, heat with gas to carry out a reduction reaction, the reaction temperature is 1000°C, and the reaction time is controlled at 2h to obtain a pre-product;

[0058] d. Cool the pre-product to 700°C, put it into NaOH solution with a temperature of 80°C and a concentration of 75% for leaching for 4 hours, after leaching, take the supernatant, concentrate and dr...

Embodiment 2

[0067] a. Take 1kg of vanadium precipitation wastewater evaporating crystallization solution, and evaporate the vanadium precipitation wastewater evaporating crystallization solution by segmented heating. The process of segmented heating is: first heat at 1075°C for 0.25h; then heat at 1085°C for 0.5h ; Finally heated at 1145 ° C for 0.75h. After evaporating, the water content of vanadium precipitation wastewater evaporating crystallization solution is 4.8%;

[0068] b. Pulverize the pulverized coal until the particle size is less than 3mm;

[0069] c. Mix the dried raw material and pulverized coal in a weight ratio of 250:51, heat with gas to carry out a reduction reaction, the reaction temperature is 1000°C, and the reaction time is controlled at 2h to obtain a pre-product;

[0070] d. Cool the pre-product to 700°C, put it into a NaOH solution with a temperature of 80°C and a concentration of 75% for leaching for 4 hours, after leaching, take the supernatant, concentrate an...

Embodiment 3

[0073] a. Take 1kg of vanadium precipitation wastewater evaporating crystallization solution, and evaporate the vanadium precipitation wastewater evaporating crystallization solution by segmented heating. The process of segmented heating is: first heat at 1000 °C for 0.25h; then heat at 1135 °C for 0.5h ; Finally heated at 1175 ℃ for 0.75h. After evaporating, the water content of vanadium precipitation wastewater evaporating crystallization solution is 4.9%;

[0074] b. Pulverize the pulverized coal until the particle size is less than 3mm;

[0075] c. Mix the dried raw material and pulverized coal in a weight ratio of 250:51, heat with gas to carry out a reduction reaction, the reaction temperature is 1000°C, and the reaction time is controlled at 2h to obtain a pre-product;

[0076] d. Cool the pre-product to 700°C, put it into a NaOH solution with a temperature of 80°C and a concentration of 75% for leaching for 4 hours, after leaching, take the supernatant, concentrate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com