High-performance cement with large mixed material mixing amount and preparation method therefor

A high-performance, mixed material technology, applied in the field of cement manufacturing, can solve the problems of not being able to maximize the utilization of solid waste, large amount of silicate clinker, and limited amount of mixed material, and achieve good social and environmental benefits , Reduce the amount of clinker and improve the utilization rate of solid waste

Inactive Publication Date: 2015-08-26

CHINA RESOURCES CEMENT TECH RES DEV

View PDF1 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the prior art, there are many studies on the compounding of mineral powder and fly ash mixed into the Portland clinker to prepare cement, but the existing research methods are limited to the amount of mineral powder and fly ash and ( total content) on the performance of cement

The result of this research method is that when mineral powder and fly ash are mixed to prepare high-performance cement products, the total amount of the two mixed mate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0020] In the case of fixed admixture content, the influence of different admixture ratios on cement performance is investigated:

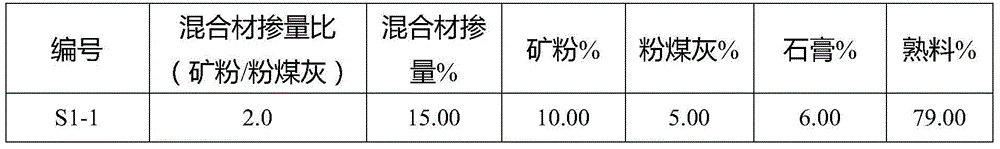

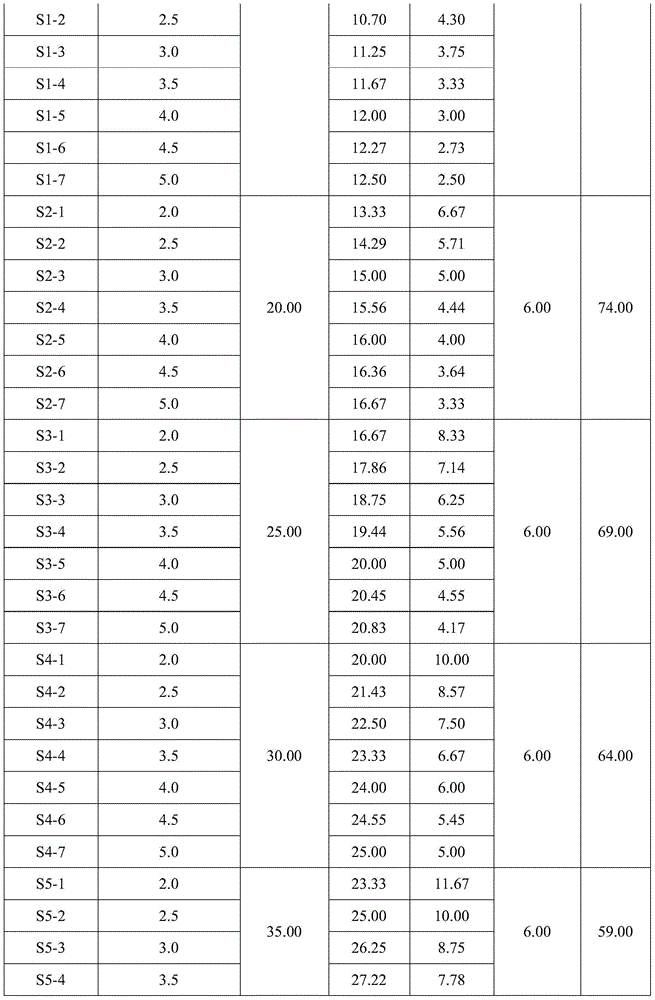

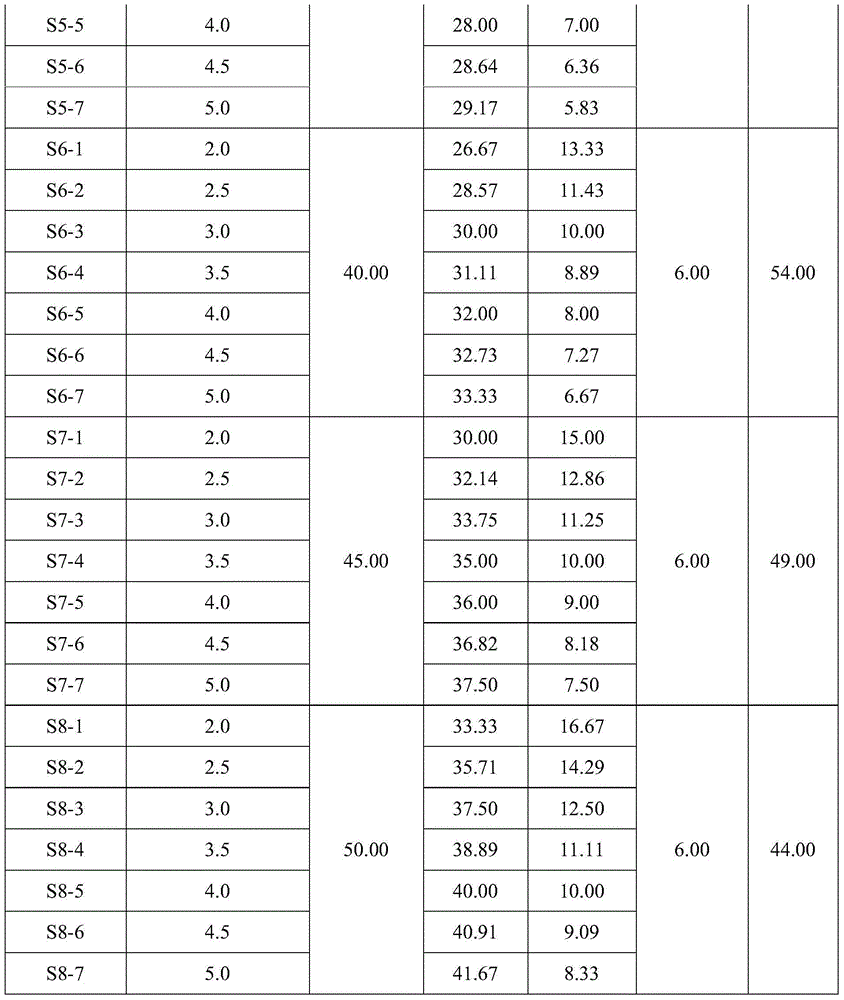

[0021] Table 1 is the cement formula of different experimental groups in this experiment:

[0022] Table 1: Cement formulations of each experimental group

[0023]

[0024]

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses high-performance cement with a large mixed material mixing amount and a preparation method therefor. The cement contains mineral powder and pulverized coal ash, wherein the total amount of the mineral powder and the pulverized coal ash used accounts for 15-50% of the mass of the cement, and the use amount ratio of the mineral powder to the pulverized coal ash is (3.5-5.0): 1. According to the invention, being different from the existing research on the influence on the performance of the cement caused by mixed materials from the aspect of mixed material mixing amount, the influence on the performance of the cement caused by the mixed materials is researched from the aspect of mixed material mixing amount ratio; and after the mixed material mixing amount ratio is determined, the consumption of the mixed materials can be increased as high as possible in a certain mixing amount range, the utilization ratio of solid wastes is increased, and the consumption of clinker is lowered, so that the production cost is reduced on one hand, and good social and environment-friendly benefits are brought on the other hand.

Description

technical field [0001] The invention belongs to the field of cement manufacture, and in particular relates to a high-performance cement with optimized mixing materials (referring to mineral powder and fly ash) and a preparation method thereof. Background technique [0002] In the prior art, there are many studies on the compounding of mineral powder and fly ash mixed into the Portland clinker to prepare cement, but the existing research methods are limited to the amount of mineral powder and fly ash and ( total content) on the performance of cement. The result of this research method is that when mineral powder and fly ash are mixed to prepare high-performance cement products, the total amount of the two mixed materials cannot exceed a certain critical value. When this critical value is exceeded, the cement performance will be reduced. Affected, so the amount of the mixture in the clinker is limited. In this way, on the one hand, the amount of mixed materials is limited, a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B7/26

CPCY02P40/10

Inventor 张琴琴谢任芝赵思源林永权

Owner CHINA RESOURCES CEMENT TECH RES DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com