Lepidolite tailing one-step sintered microcrystalline foam heat preservation and decoration integrated plate

A lepidolite and integrated board technology, applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of poor combination effect of decorative surface layer and insulation layer, easy cracking and wear resistance of decorative surface, rock wool insulation board It is easy to absorb water and other problems, so as to improve the thermal insulation effect, eliminate the residual stress and increase the toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

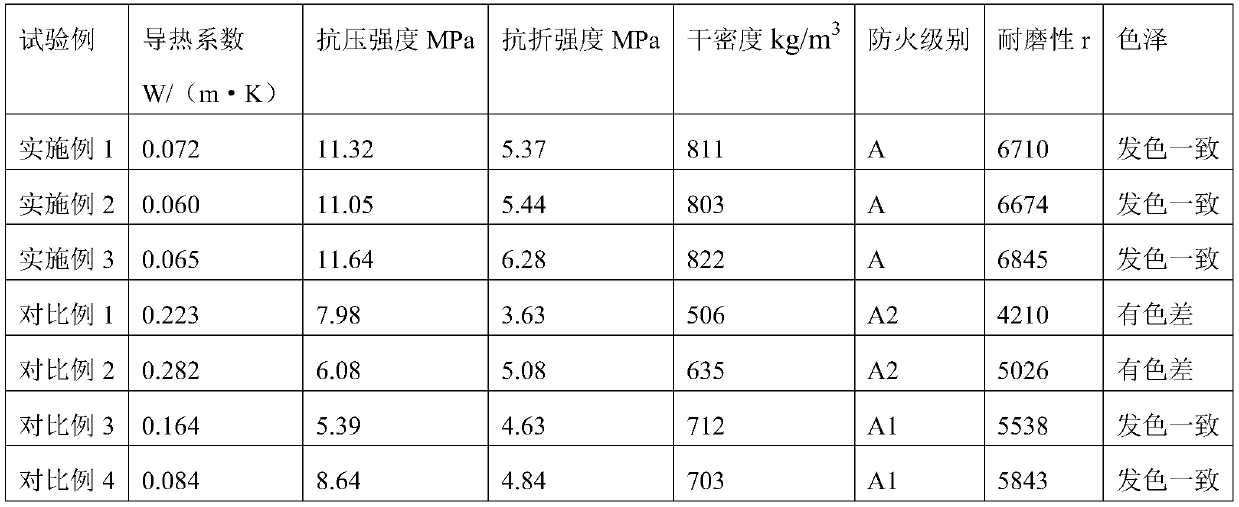

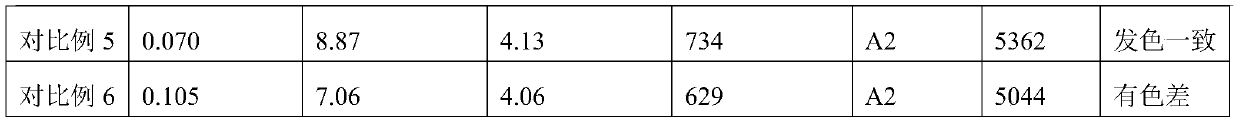

Embodiment 1

[0028] Prepare the thermal insulation and decoration integrated board according to the following methods:

[0029] Raw material of microcrystalline foamed lightweight layer:

[0030] 45 parts of lepidolite tailings, 10 parts of clay, 8 parts of industrial waste phosphogypsum, 7 parts of red mud, 10 parts of construction waste, 3 parts of domestic waste incineration fly ash, 3 parts of kaolin, 1 part of graphene, 8 parts of polishing slag, 5 parts of foaming agent, 32 parts of cement mortar, 6 parts of microfoam agent, 4 parts of waterproof powder, 7 parts of lime, 24 parts of water, 10 parts of clay, 12 parts of concrete, 3 parts of wood fiber, and 3 parts of cellulose ether.

[0031] Microcrystalline wear-resistant decorative surface layer raw materials:

[0032] 25 parts of kaolin, 13 parts of silica, 20 parts of red clay, 11 parts of purple shale, 4 parts of perlite, 1 part of fine pearlite powder, 3 parts of graphene, 5 parts of silicon carbide, 6 parts of industrial sili...

Embodiment 2

[0044] Raw material of microcrystalline foamed lightweight layer:

[0045] 40 parts of lepidolite tailings, 6 parts of clay, 12 parts of industrial waste phosphogypsum, 5 parts of red mud, 14 parts of construction waste, 5 parts of domestic waste incineration fly ash, 1 part of kaolin, 3 parts of graphene, 12 parts of polishing slag, 3 parts of foaming agent, 38 parts of cement mortar, 4 parts of microfoam agent, 6 parts of waterproof powder, 5 parts of lime, 20 parts of water, 8 parts of clay, 16 parts of concrete, 1 part of wood fiber, and 1 part of cellulose ether.

[0046] Microcrystalline wear-resistant decorative surface layer raw materials:

[0047] 21 parts of kaolin, 17 parts of silica, 24 parts of red clay, 15 parts of purple shale, 2 parts of perlite, 3 parts of pearlite fine powder, 1 part of graphene, 7 parts of silicon carbide, 4 parts of industrial silicon slag, flame retardant 5 parts of agent, 4 parts of water glass.

[0048] The polishing slag is silicon carb...

Embodiment 3

[0053] Raw material of microcrystalline foamed lightweight layer:

[0054] 42 parts of lepidolite tailings, 8 parts of clay, 10 parts of industrial waste phosphogypsum, 6 parts of red mud, 12 parts of construction waste, 4 parts of domestic waste incineration fly ash, 2 parts of kaolin, 2 parts of graphene, 10 parts of polishing slag, 4 parts of foaming agent, 35 parts of cement mortar, 5 parts of microfoam agent, 5 parts of waterproof powder, 6 parts of lime, 22 parts of water, 9 parts of clay, 14 parts of concrete, 2 parts of wood fiber, and 2 parts of cellulose ether.

[0055] Microcrystalline wear-resistant decorative surface layer raw materials:

[0056] 23 parts of kaolin, 15 parts of silica, 22 parts of red clay, 13 parts of purple shale, 3 parts of perlite, 2 parts of pearlite fine powder, 2 parts of graphene, 6 parts of silicon carbide, 5 parts of industrial silicon slag, flame retardant 4 parts of agent, 5 parts of water glass.

[0057] Described polishing slag, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com