High-strength nickel slag-based solid waste cementing material and preparation method thereof

A technology of cementitious material and blast furnace nickel slag, which is applied in the field of building materials, can solve the problems of transferring to surrounding soil and groundwater, reducing the durability of cement test blocks, and the utilization rate of less than 10%, so as to solve the utilization rate of nickel slag. Low, dense voids, high solid waste utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

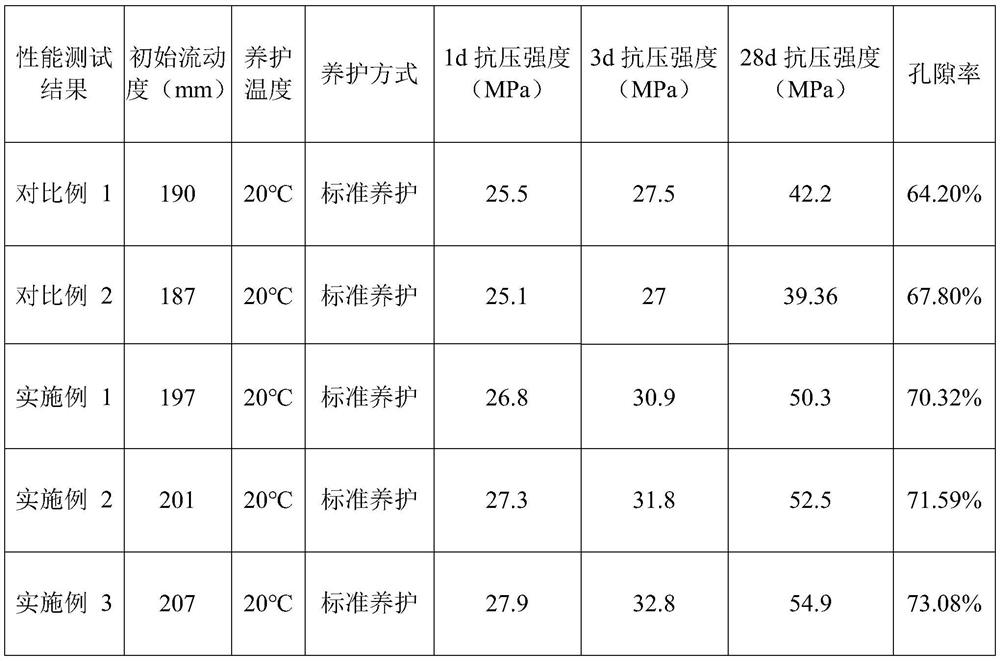

Examples

Embodiment 1

[0028] 1) Put the steel slag, blast furnace nickel slag, and phosphogypsum in a crusher to crush, and the crushed particle size is 2-10mm.

[0029] 2) Take 100 parts of crushed steel slag and 400 parts of blast furnace nickel slag in a wet mill, add 150 parts of water, and then add 3 parts of naphthalene-based water reducer, and wet grind at 400r / min for 20min to a particle size below 5μm. A slurry is prepared.

[0030] 3) Take the slurry obtained in step 2) in a mixing pot, add 400 parts of crushed phosphogypsum, use a cement mortar mixer to stir evenly for 15 seconds, and finally mix in 100 parts of cement clinker and 160 parts of externally mixed The water was continuously stirred for 6 minutes (stir slowly at a speed of 65r / min for 3 minutes, stop for 15 seconds, then stir quickly at a speed of 130r / min for 3 minutes), to obtain a nickel slag-based solid waste cementitious material.

Embodiment 2

[0032] 1) Put the steel slag, blast furnace nickel slag, and phosphogypsum in a crusher to crush, and the crushed particle size is 2-10mm.

[0033] 2) Take 100 parts of crushed steel slag and 450 parts of blast furnace nickel slag in a wet mill, add 165 parts of water, and then add 3 parts of naphthalene-based water reducer, and wet grind at 400r / min for 30min to a particle size of 5μm Next, a slurry was prepared.

[0034] 3) Take the slurry obtained in step 2) in a mixing pot, add 350 parts of crushed phosphogypsum, use a cement mortar mixer to stir evenly for 15 seconds, and finally mix in 100 parts of cement clinker and 140 parts of externally mixed The water was continuously stirred for 6 minutes (stir slowly at a speed of 65r / min for 3 minutes, stop for 15 seconds, then stir quickly at a speed of 130r / min for 3 minutes), to obtain a nickel slag-based solid waste cementitious material.

Embodiment 3

[0036] 1) Put the steel slag, blast furnace nickel slag, and phosphogypsum in a crusher to crush, and the crushed particle size is 2-10mm.

[0037]2) Take 100 parts of crushed steel slag and 500 parts of blast furnace nickel slag in a wet mill, add 180 parts of water, add 3 parts of naphthalene-based water reducing agent, and wet grind at 400r / min for 40min to a particle size below 5μm , to prepare slurry.

[0038] 3) Take the slurry obtained in step 2) in a mixing pot, add 300 parts of crushed phosphogypsum, use a cement mortar mixer to stir evenly for 15 seconds, and finally mix in 100 parts of cement clinker and 120 parts of externally mixed The water was continuously stirred for 6 minutes (stir slowly at a speed of 65r / min for 3 minutes, stop for 15 seconds, then stir quickly at a speed of 130r / min for 3 minutes), to obtain a nickel slag-based solid waste cementitious material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com