Method for preparing photocatalyst with core-shell structure

A technology of core-shell structure and photocatalyst, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of cumbersome preparation process, high energy consumption, large nano-titanium dioxide grains, etc., and achieve the goal of preparing The effect of simple process, high catalytic activity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

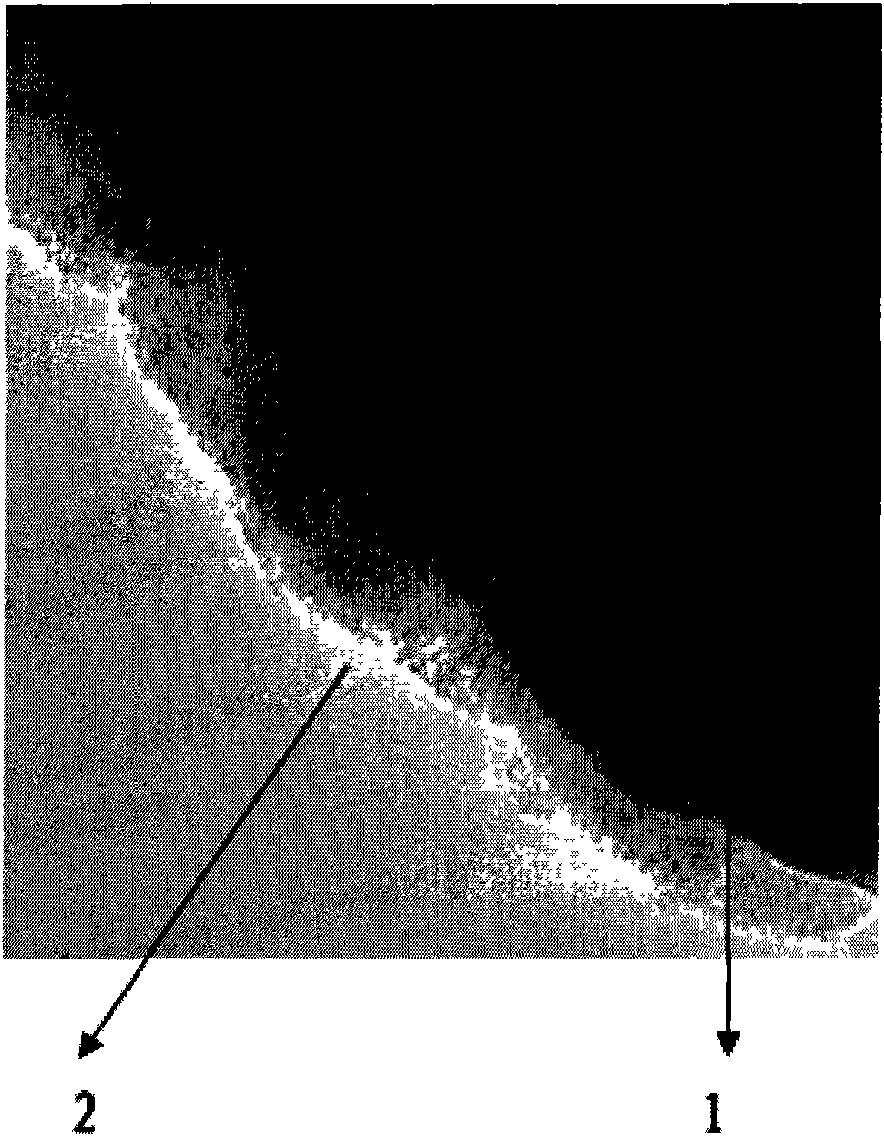

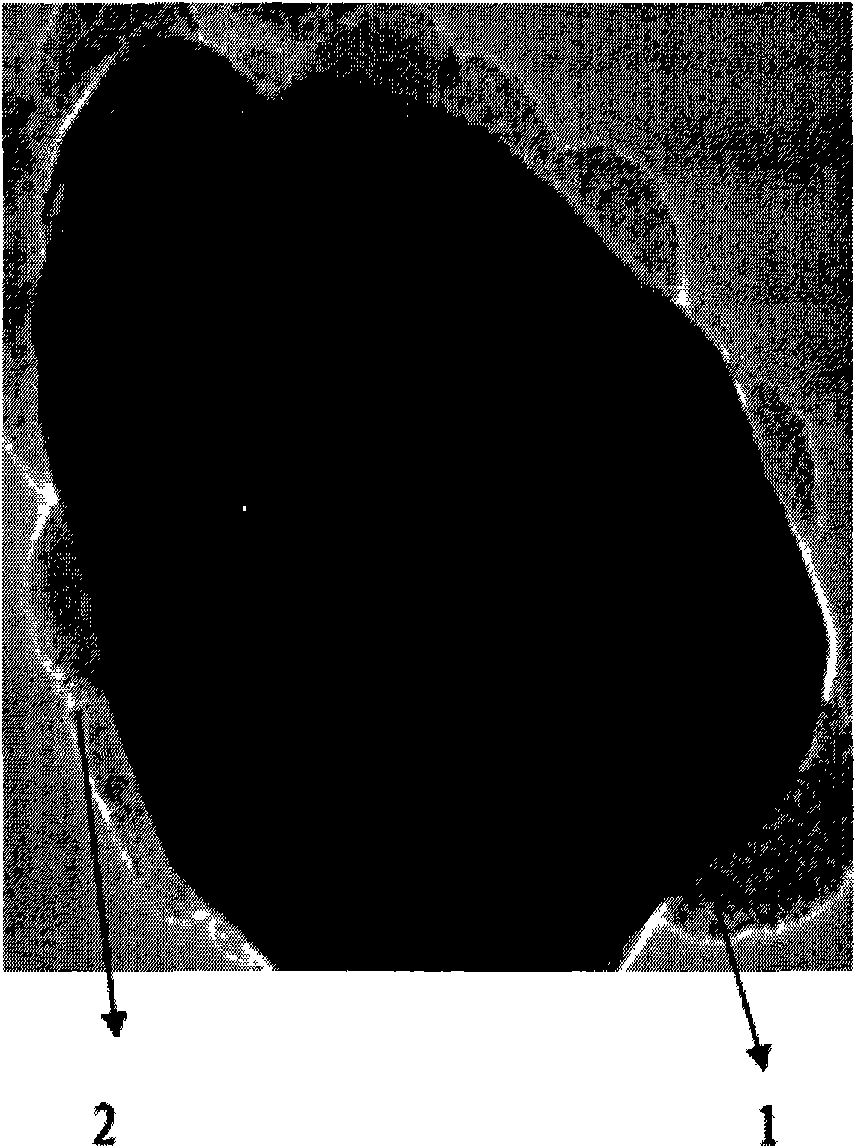

Image

Examples

Embodiment 1

[0038] 1. Activation of acid-resistant non-metallic ores or non-metallic synthetic compounds and removal of acid-soluble impurities:

[0039] 1. Disperse 800 grams of 1250 mesh barium sulfate in 1500 milliliters of 20% hydrochloric acid solution to prepare a suspension,

[0040] 2. Maintain the stirring speed at 150 rpm, temperature at 75°C for 2 hours,

[0041] 3. Cool, filter, and wash with water until there is no Cl - .

[0042] Two, titanium tetrachloride secondary hydrolyzate preparation:

[0043] 1. Dissolve 3 grams of polyethylene glycol 2000 in 150 milliliters of 20% hydrochloric acid solution;

[0044] 2. Add the mixed solution configured in step 1 dropwise to 120 ml of titanium tetrachloride solution to obtain a brown-black hydrolyzate;

[0045] 3. Add 0.4 g of sodium octadecyl sulfate to the hydrolyzate in step 2, maintain the temperature at 85° C., maintain the stirring speed at 300 rpm, and stir and heat for 1 hour.

[0046] 3. Core-shell deposition coating: ...

Embodiment 2

[0051] 1. Activation of acid-resistant non-metallic ores or non-metallic synthetic compounds and removal of acid-soluble impurities:

[0052] 1. Disperse 800 grams of 12500 mesh mica in 2400 milliliters of 10% hydrochloric acid solution to prepare a suspension,

[0053] 2. Maintain the stirring speed at 100 rpm, temperature at 85°C for 4 hours,

[0054] 3. Cool, filter, and wash with water until there is no Cl - .

[0055] Two, titanium tetrachloride secondary hydrolyzate preparation:

[0056] 1. Dissolve 5 grams of sodium polyacrylate and polyethylene glycol 2000 in 240 milliliters of 10% hydrochloric acid solution;

[0057] 2. Add the mixed solution configured in step 1 dropwise to 120 ml of titanium tetrachloride solution to obtain a brown-black hydrolyzate;

[0058] 3. Add 0.5 g of sodium octadecyl sulfate to the hydrolyzate in step 2, maintain the temperature at 90° C., maintain the stirring speed at 300 rpm, and stir and heat for 3 hours.

[0059] 3. Core-shell depo...

Embodiment 3

[0064] 1. Activation of acid-resistant non-metallic ores or non-metallic synthetic compounds and removal of acid-soluble impurities:

[0065] 1. Disperse 800 grams of 800 mesh kaolin in 5600 milliliters of 25% hydrochloric acid solution to prepare a suspension,

[0066] 2. Maintain the stirring speed at 150 rpm, temperature at 50°C for 0.5 hours,

[0067] 3. Cool, filter, and wash with water until there is no Cl - .

[0068] Two, titanium tetrachloride secondary hydrolyzate preparation:

[0069] 1. Dissolve 7 grams of sodium polyacrylate in 560 milliliters of 25% hydrochloric acid solution;

[0070] 2. Add the mixed solution configured in step 1 dropwise to 120 ml of titanium tetrachloride solution to obtain a brown-black hydrolyzate;

[0071] 3. Add 0.6 g of sodium octadecyl sulfate to the hydrolyzate in step 2, maintain the temperature at 40° C., maintain the stirring speed at 300 rpm, and stir and heat for 0.5 hours.

[0072] 3. Core-shell deposition coating:

[0073]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com