Method for preparation of lithium tantalate nano-powder by hydrothermal process

A nano-powder, lithium tantalate preparation technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficulty in synthesizing nanoparticles, requiring high temperature, and long reaction time, etc. Achieve the effect of small, complete and uniform grains, low reaction temperature and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

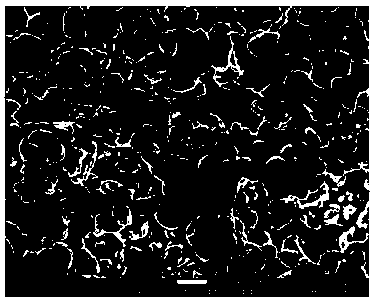

[0023] Add 150mL of reaction solvent deionized water into the autoclave with magnetic rotation stirring, then add 1g Li 2 CO 3 and 3.59g Ta(OH) 5 , to ensure that the molar ratio of tantalum ions to lithium ions is 1:2, react for 12 hours, and the reaction temperature is 240 ° C. After the reaction is completed, wash twice with deionized water, and then wash twice with ethanol to obtain lithium tantalate nanoparticles. Powder. The scanning electron microscope picture of lithium tantalate nanopowder is attached figure 1 , the grain size is 100-150nm, the powder has no impurities, the crystallinity is good and there is no impurity phase, the crystal is square columnar, and there is no agglomeration phenomenon.

Embodiment 2

[0025] Add 180mL of reaction solvent deionized water into the autoclave with magnetic rotation stirring, then add 1g Li 2 CO 3 and 2.983g Ta 2 o 5 , to ensure that the molar ratio of tantalum ions to lithium ions is 1:2, react for 12 hours, and the reaction temperature is 240 ° C. After the reaction is completed, wash twice with deionized water, and then wash twice with ethanol to obtain lithium tantalate nanoparticles. Powder. Lithium tantalate nano-powder has a grain size of 200-250nm, and the powder has no impurities, good crystallinity, no impurity phase, and regular shape.

Embodiment 3

[0027] Add 200mL of reaction solvent deionized water into the autoclave with magnetic rotation stirring, then add 1g LiOH and 2.63g Ta 2 o 5 , to ensure that the molar ratio of tantalum ions to lithium ions is 1:3.5, react for 12 hours, and the reaction temperature is 240 ° C. After the reaction, wash twice with deionized water, and then wash twice with ethanol to obtain lithium tantalate nanoparticles Powder. Lithium tantalate nano-powder has a grain size of 250-300nm, and the powder has no impurities, good crystallinity, no impurity phase, and regular shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com