Method for direct synthesis of Mn<+>-doped SnO2 nanocrystals with one-step hydrothermal method

A hydrothermal method and nanocrystalline technology, applied in the field of photocatalytic materials, can solve the problems of expensive equipment, high production cost, low yield, etc., and achieve the effects of simple equipment, easy control of conditions, and no template assistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

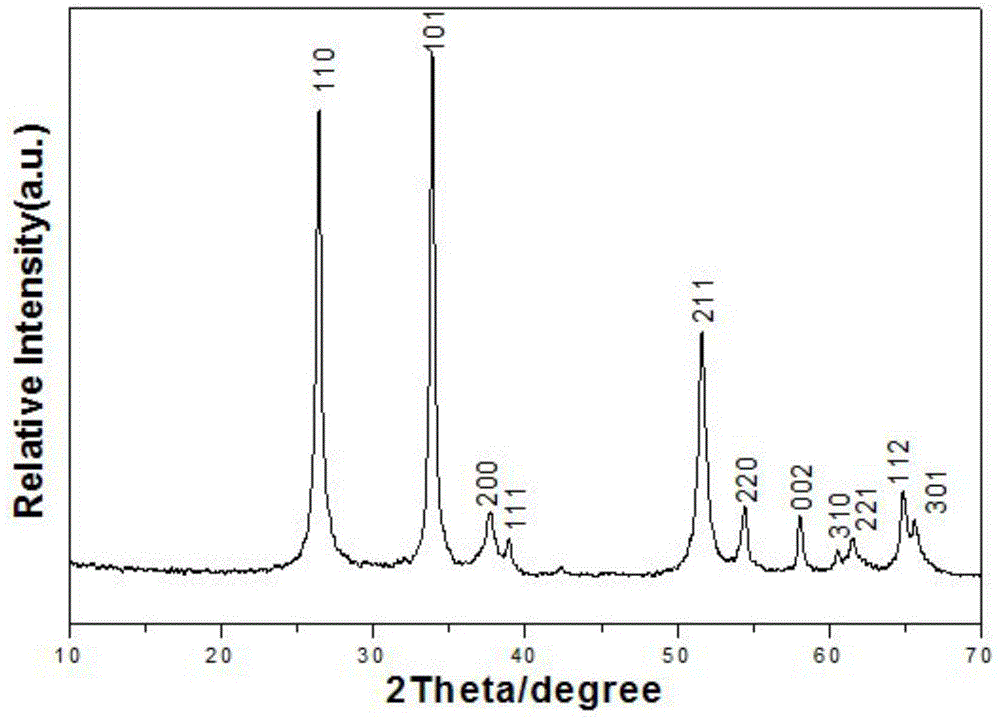

[0022] Example 1: Flower-shaped doping with Zn 2+ SnO 2 Hydrothermal Preparation of Nanocrystals

[0023] The first step, now will contain 3mmol of SnCl 4 5H 2 O solution was added dropwise to NaOH solution containing 20 mmol, under the condition of magnetic stirring, until a stable and transparent solution was formed.

[0024] In the second step, the ZnCl containing 0.3mmol 2 The solution was added dropwise to the above solution, under the condition of magnetic stirring until a stable suspension was formed.

[0025] In the third step, the above-mentioned suspension is transferred to a high-pressure reaction kettle with a capacity of 60mL polytetrafluoroethylene inner bag, and then water is added to 80%, and the rear seal is put into an oven, and a certain reaction time is set. 36 h and a reaction temperature of 200 °C.

[0026] In the fourth step, after the autoclave is naturally cooled, the precipitate in the autoclave is centrifuged and washed several times, and then ...

Embodiment 2

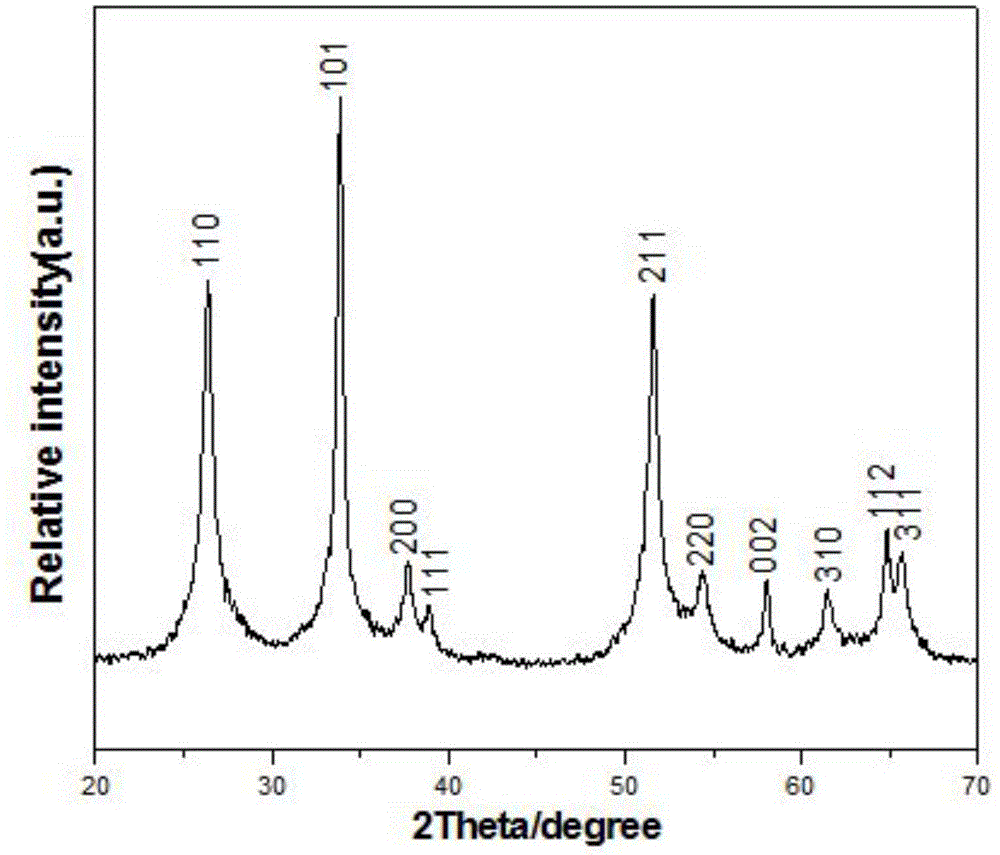

[0028] Embodiment 2 doping Mn 2+ SnO 2 Hydrothermal Preparation of Nanocrystals

[0029] The first step, now will contain 5mmol of SnCl 4 5H 2 O solution was added dropwise to NaOH solution containing 35 mmol, under the condition of magnetic stirring, until a stable and transparent solution was formed.

[0030] In the second step, the MnCl containing 0.5mmol 2 The solution was added dropwise to the above solution, under the condition of magnetic stirring until a stable suspension was formed.

[0031] In the third step, the above-mentioned suspension is transferred to a high-pressure reaction kettle with a capacity of 60mL polytetrafluoroethylene inner bag, and then water is added to 80%, and the rear seal is put into an oven, and a certain reaction time is set. 36 h and a reaction temperature of 140 °C.

[0032] In the fourth step, after the autoclave is naturally cooled, the precipitate in the autoclave is centrifuged and washed several times, and then dried in an oven ...

Embodiment 3

[0033] Example 3 doping Co 2+ SnO 2 Hydrothermal Preparation of Nanocrystals

[0034] The first step, now will contain 4mmol of SnCl 4 5H 2 O solution was added dropwise to NaOH solution containing 30 mmol, under the condition of magnetic stirring, until a stable and transparent solution was formed.

[0035] In the second step, the CoCl containing 0.4mmol 2 The solution was added dropwise to the above solution, under the condition of magnetic stirring until a stable suspension was formed.

[0036] In the third step, the above-mentioned suspension is transferred to a high-pressure reaction kettle with a capacity of 60mL polytetrafluoroethylene inner bag, and then water is added to 80%, and the rear seal is put into an oven, and a certain reaction time is set. 24 h and a reaction temperature of 170 °C.

[0037] In the fourth step, after the autoclave is naturally cooled, the precipitate in the autoclave is centrifuged and washed several times, and then dried in an oven at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com