Method for preparing strontium titanate nano powder through microwave hydrothermal method

A microwave hydrothermal method and nano-powder technology, applied in the field of nano-materials, can solve the problems of strong corrosion of high-concentration sodium hydroxide, increased consumption of underwear materials, and poor product dispersion. It is not easy to achieve particles, low cost, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

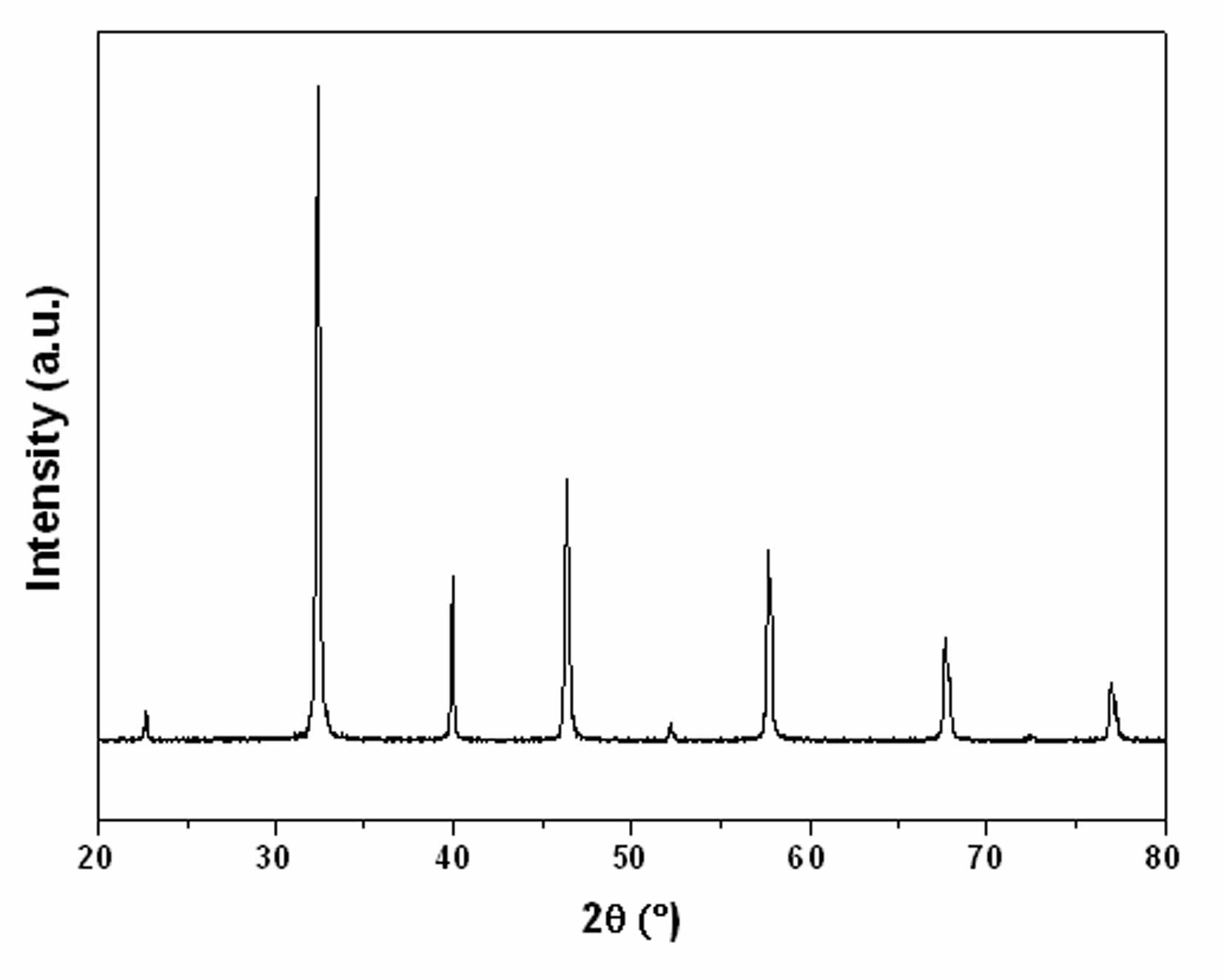

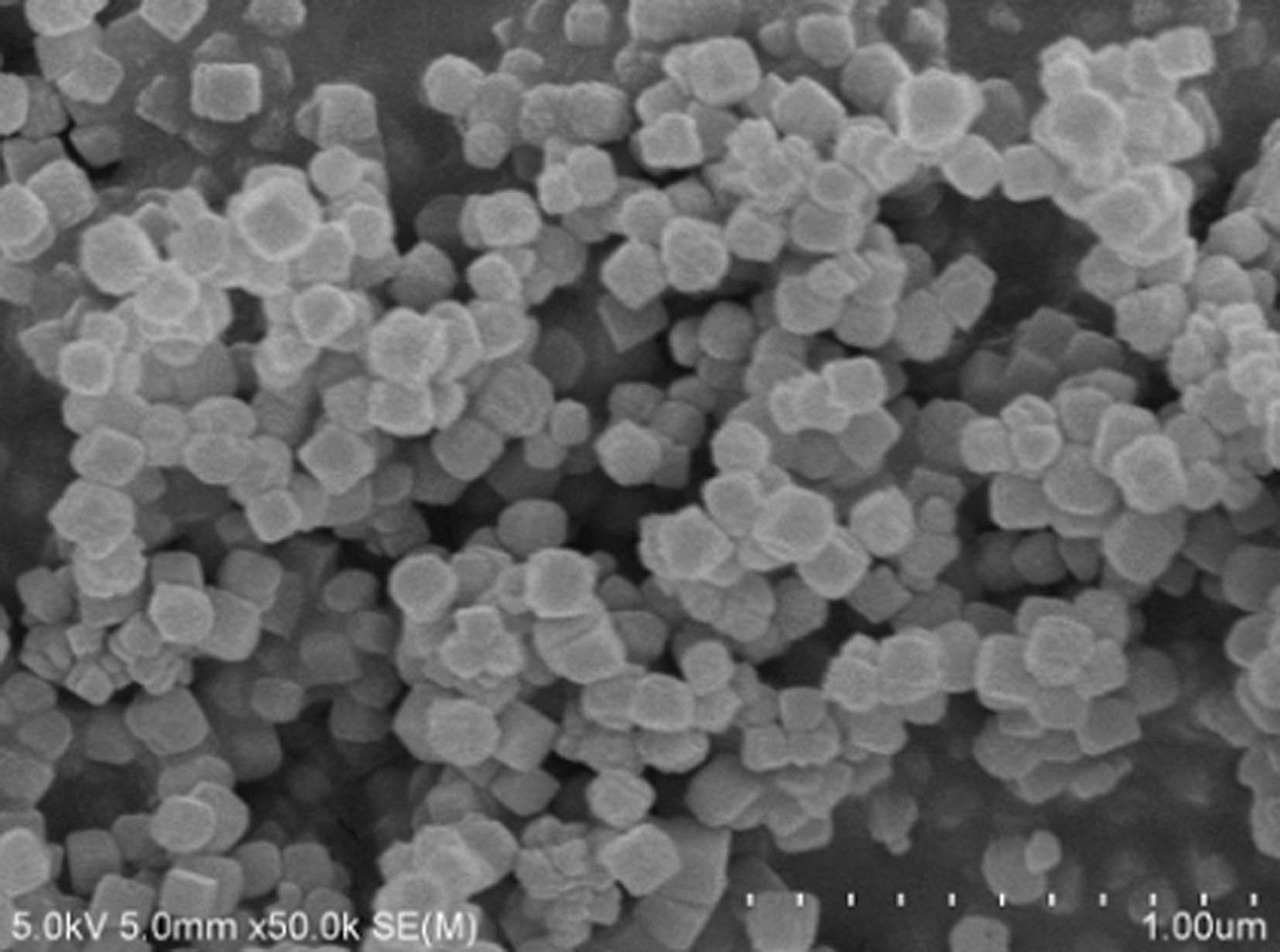

Image

Examples

Embodiment 1

[0028] 1) Measure 1.0ml of butyl titanate, add it to 25ml of absolute ethanol, add 5ml of glacial acetic acid, and magnetically stir until dissolved to obtain solution A;

[0029] 2) Weigh 0.6349g of strontium nitrate, add it into 30ml of deionized water, and magnetically stir until dissolved to obtain solution B;

[0030] 3) While stirring, add solution B dropwise to solution A, and continue stirring for at least 10 minutes until a homogeneous sol is formed;

[0031] 4) Weigh 4.0000g of sodium hydroxide and add it into the sol under stirring to form a precursor slurry with a pH value of 14;

[0032] 5) Put the precursor slurry into a polytetrafluoroethylene-lined reactor for microwave hydrothermal reaction. The filling degree of the reactor is 60%, the reaction temperature is 180°C, the reaction time is 1h, and the microwave power is 400W. The product after the microwave hydrothermal reaction was fully washed with deionized water and absolute ethanol, filtered, a...

Embodiment 2

[0035] 1) Measure 1.7ml of butyl titanate, add it to 25ml of absolute ethanol, and add 5ml of glacial acetic acid, stir magnetically until dissolved to obtain solution A;

[0036] 2) Weigh 1.0582g of strontium nitrate, add it into 30ml of deionized water, and magnetically stir until dissolved to obtain solution B;

[0037] 3) While stirring, add solution B dropwise to solution A, and continue stirring for at least 10 minutes until a homogeneous sol is formed;

[0038] 4) Weigh 4.0000g of sodium hydroxide and add it into the sol under stirring to form a precursor slurry with a pH value of 14;

[0039] 5) Put the precursor slurry into a polytetrafluoroethylene-lined reactor for microwave hydrothermal reaction. The filling degree of the reactor is 60%, the reaction temperature is 180°C, the reaction time is 1h, and the microwave power is 400W. The product after the microwave hydrothermal reaction was fully washed with deionized water and absolute ethanol, filtered, a...

Embodiment 3

[0041] 1) Measure 1.0ml of butyl titanate, add it to 25ml of absolute ethanol, and add 5ml of glacial acetic acid, stir until dissolved by magnetic force, and obtain solution A;

[0042] 2) Weigh 0.6349g of strontium nitrate, add it into 30ml of deionized water, and magnetically stir until dissolved to obtain solution B;

[0043] 3) While stirring, add solution B dropwise to solution A, and continue stirring for at least 10 minutes until a homogeneous sol is formed;

[0044] 4) Weigh 4.0000g of sodium hydroxide and add it to the above sol under stirring to form a precursor slurry with a pH value of 14;

[0045] 5) Put the precursor slurry into a polytetrafluoroethylene-lined reactor for microwave hydrothermal reaction. The filling degree of the reactor is 70%, the reaction temperature is 150°C, the reaction time is 2 hours, and the microwave power is 400W. The product after the microwave hydrothermal reaction was fully washed with deionized water and absolute etha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com