Chemical deposition preparation method of piezoelectric composite metal electrode

A piezoelectric composite material, chemical deposition technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem of low utilization rate and production efficiency of electrode raw materials, high equipment and site requirements, and inability to bond and other problems, to achieve the effect of bright and uniform electrode coating, good bonding force and fine crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the present invention is further elaborated by implementing examples. It should be understood that the following examples are only brief descriptions of the present invention, rather than limitations of the present invention. within the scope of protection of the invention.

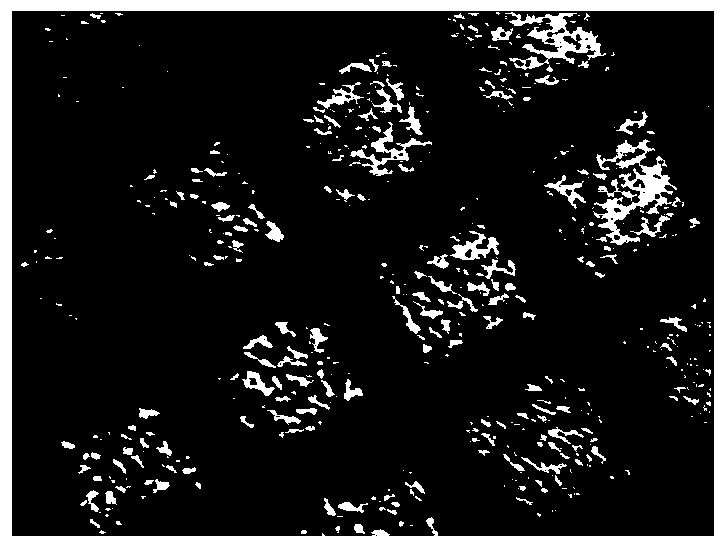

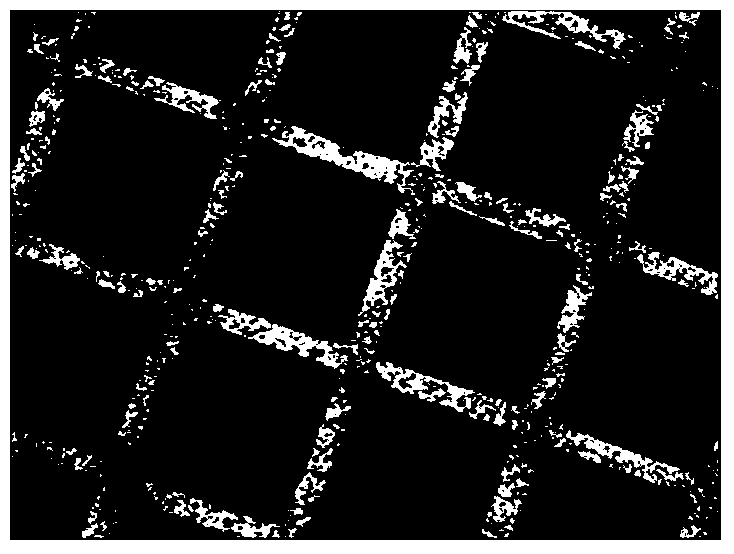

[0030] Piezoelectric composites ( figure 1 ) The metal electrode is a disc made of lead zirconate titanate ceramics and epoxy resin polymer, and the diameter of the disc is about 5 cm.

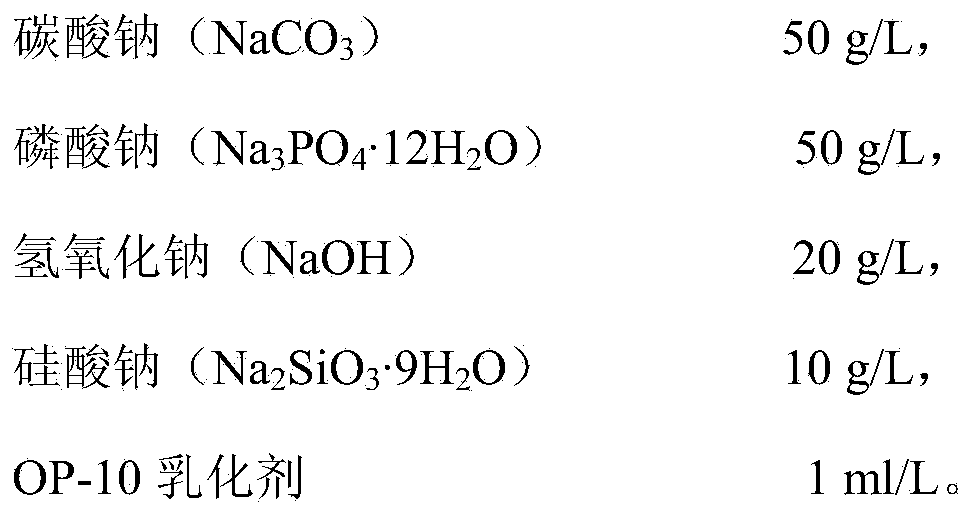

[0031] The preparation sequence is as follows: clean the piezoelectric composite material, place it in a degreasing solution at 35°C, and remove oil for 10 minutes; place it in a hydrophilic solution at 35°C, and treat it for 5 minutes; Soak for 2 minutes; in the reducing solution, soak for 1 minute at room temperature; in the two-step roughening solution, soak for 3 minutes at room temperature; in the colloidal palladium solution at 35°C, soak for 3 minutes; In the chemical deposition copper solution, the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com