Anti-slip injection molding nut

A nut, injection molding technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of insufficient friction and occlusal force, nut detachment, and weak plastic and nut embedding, etc., to increase friction and occlusion. strength, the effect of improving the firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

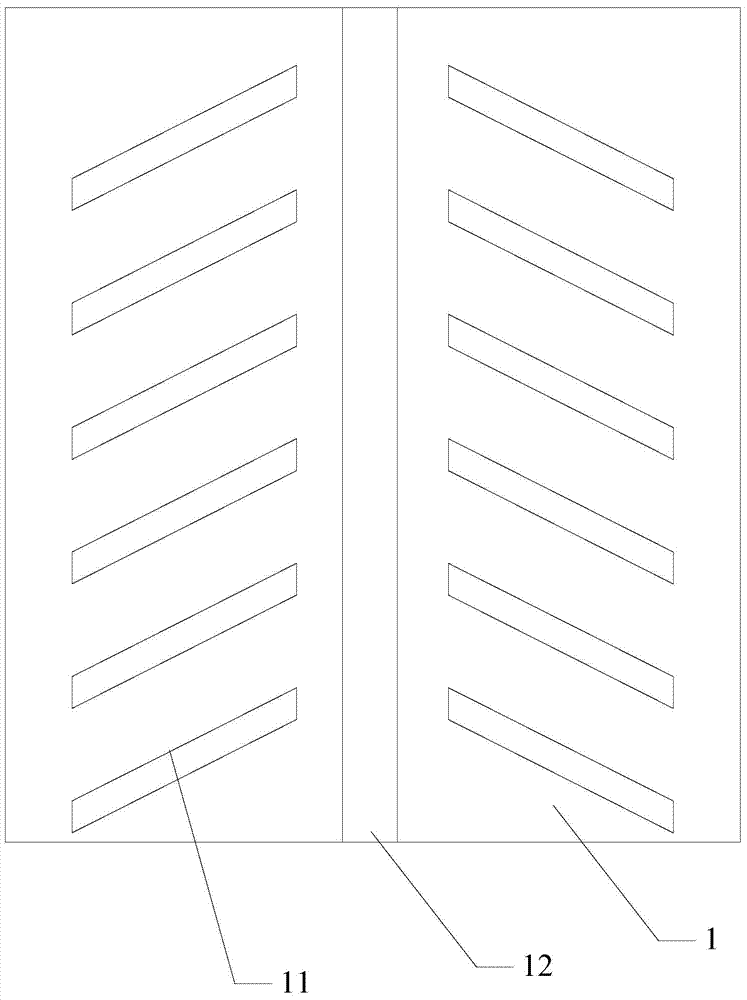

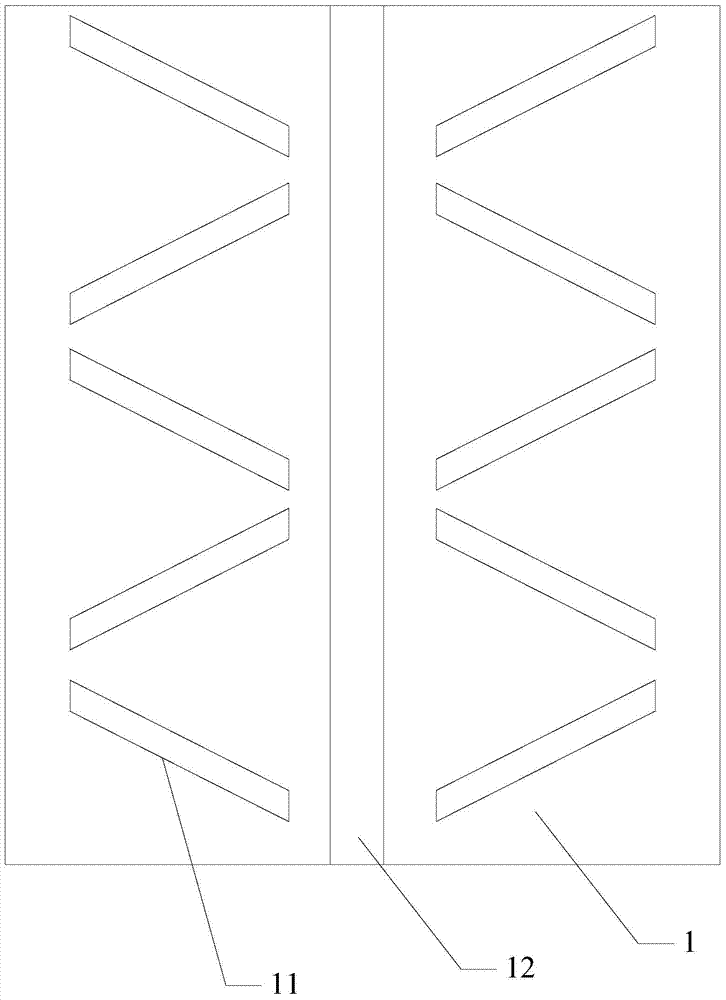

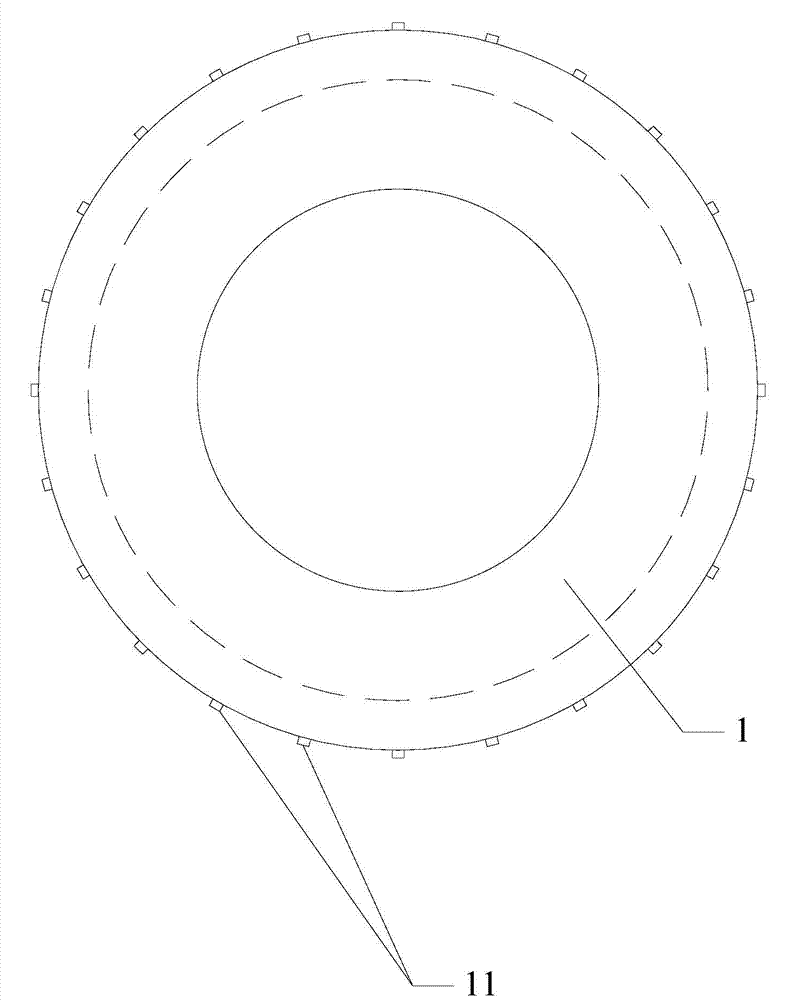

[0019] figure 1 , figure 2 and image 3 They are the side structure schematic diagram, the other side structure diagram and the bottom surface structure diagram of an anti-slip injection molding nut of the present invention; as shown in the figure, the anti-slip injection molding nut includes a nut body 1, and the nut body 1 is provided with an equatorial groove 12 , a plurality of anti-slip protrusions 11 are arranged symmetrically on both sides of the equatorial groove 12 . The anti-slip protrusions 11 on each side are arranged in parallel. Preferably, two adjacent anti-slip protrusions 11 on each side are arranged symmetrically. The included angle between each of the anti-slip protrusions 11 and the equatorial groove 12 is 30°. The width of the equatorial groove 12 is 1 / 4 of the width of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com