Roller assembly and rolling rotor compressor

A technology of compressors and rollers, which is applied in the field of compressors, can solve the problems of poor performance and easy capacity shifting, and achieve the effect of avoiding capacity shifting and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

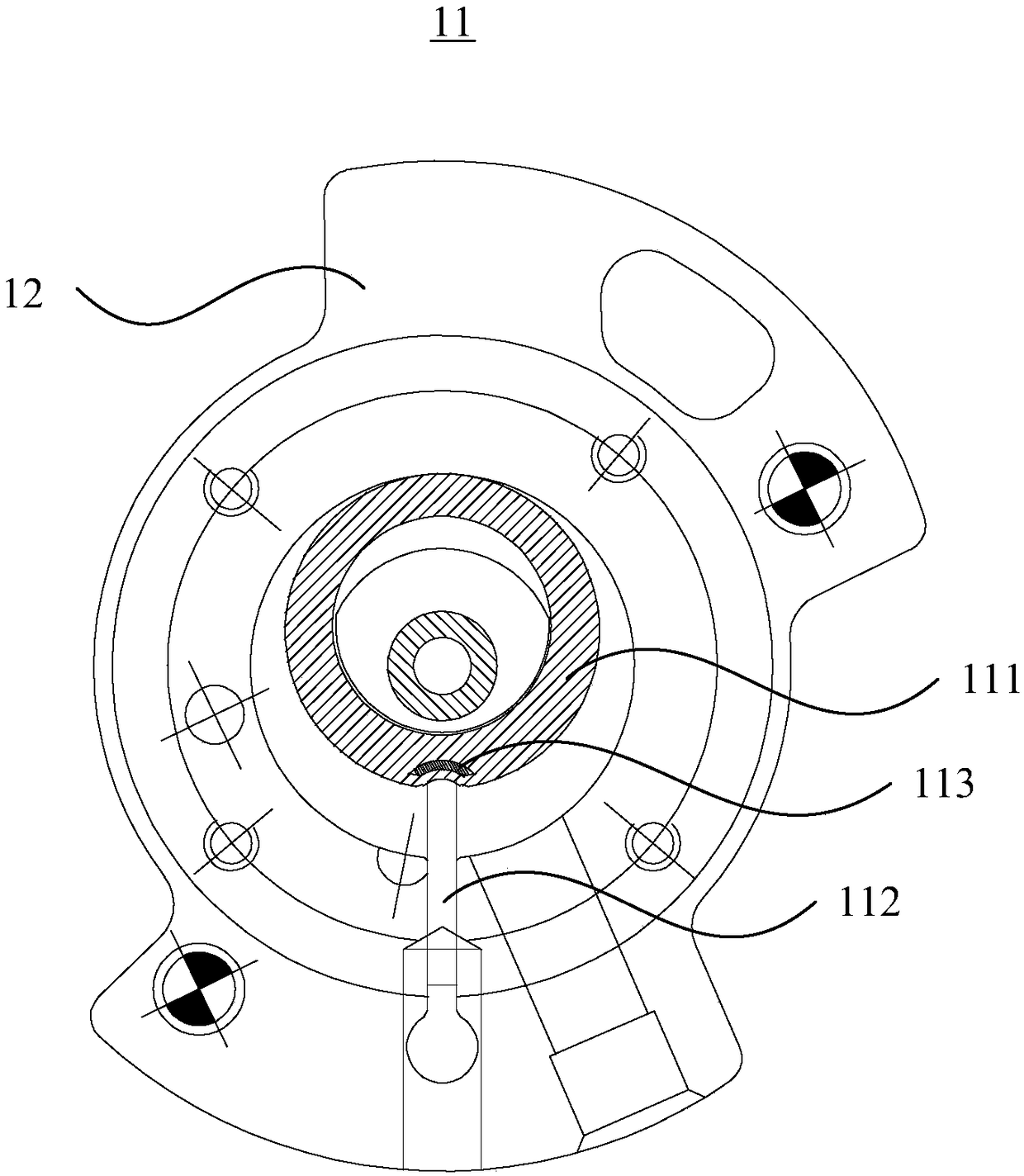

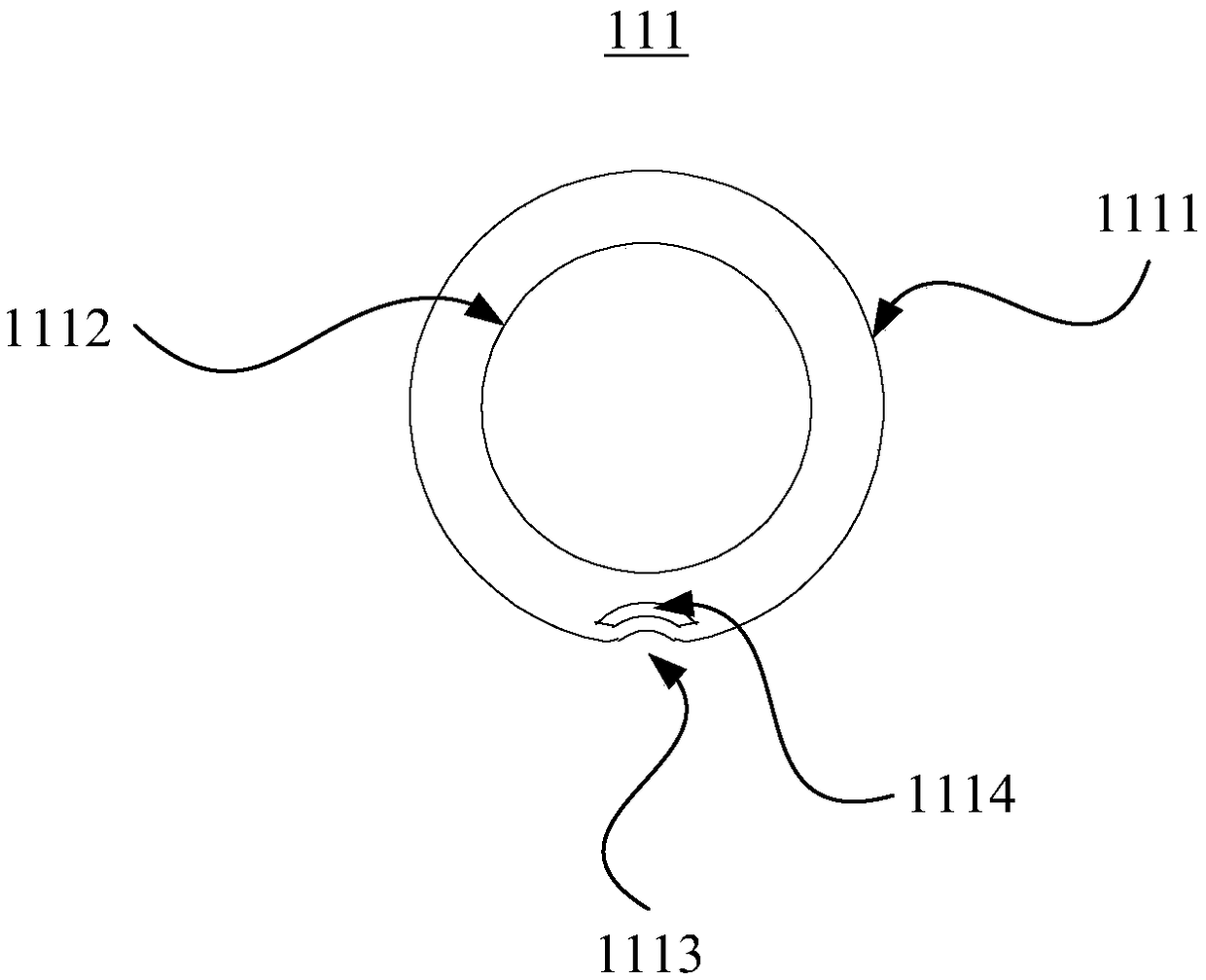

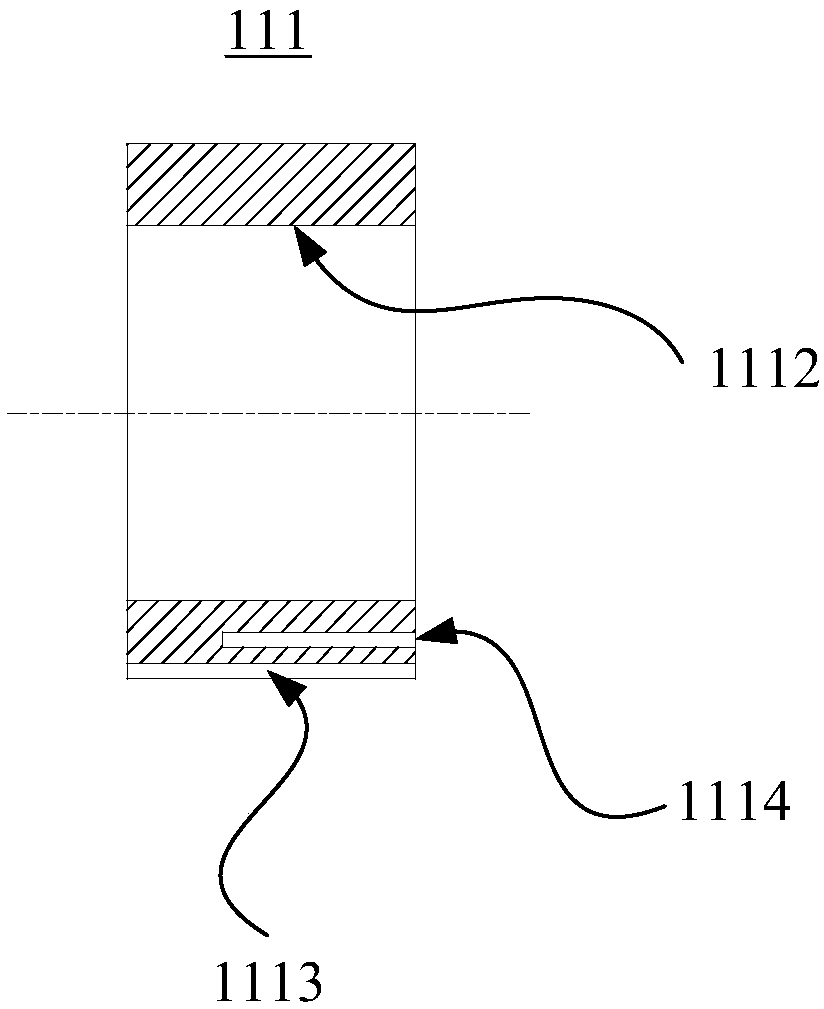

[0023] Such as figure 1 As shown, in one embodiment, a roller assembly 11 is provided, including a roller 111 and a sliding piece 112, the roller 111 can move eccentrically in the cylinder body 12, and the front end of the sliding piece 112 is magnetically attracted Abutting against the outer peripheral surface 1111 of the roller 111 , the rear end of the sliding piece 112 can be inserted into the side wall of the cylinder 12 , forming an air suction chamber and an exhaust chamber in the cylinder 12 .

[0024] The above solution provides a roller assembly 11, the front end of the slide 112 is attracted to the outer peripheral surface 1111 of the roller 111 by magnetic force, so that when the roller 111 moves eccentrically in the cylinder 12, the front end of the slide 112 The front end is always in contact with the outer peripheral surface 1111 of the roller 111, and the sliding plate 112 will not be detached from the roller 111, so that the suction chamber and the exhaust cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com