Special grease for refrigeration and prepared by mixing lard oil and palm oil and preparation method thereof

A technology of palm oil and palm ointment, which is applied in the fields of edible oil/fat, application, food science, etc., can solve the problems of coarse and uneven particles, limit the industrialization development of lard, and affect health, and achieve smooth SFC curve and fine crystallization , the effect of good processing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: binary compatibility analysis experiment of lard and palm oil

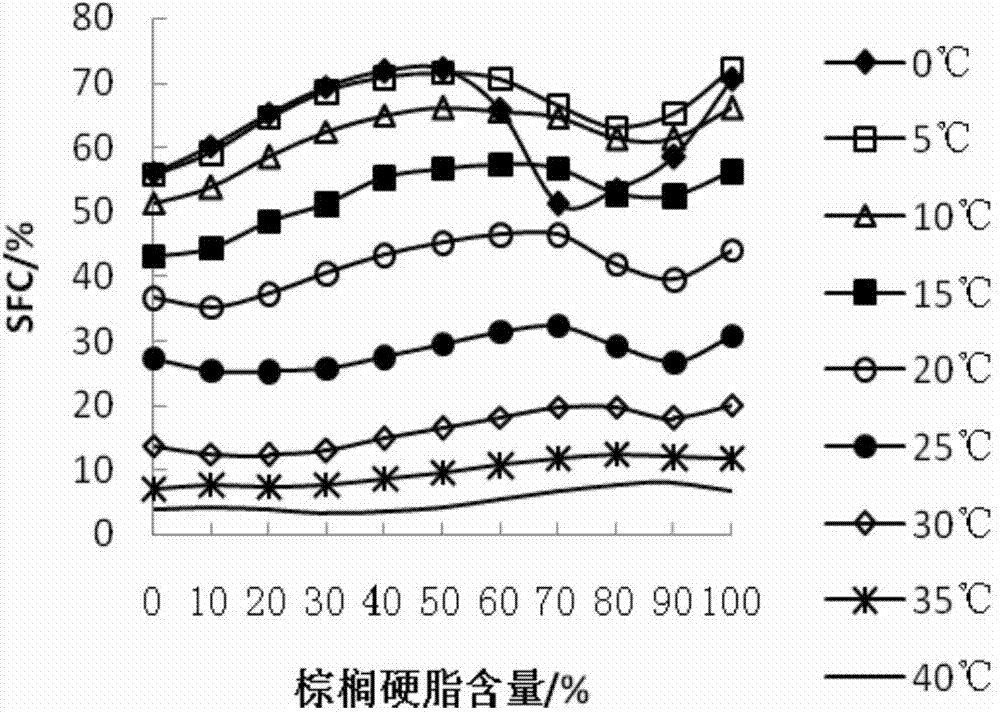

[0032] Weigh 10g of palm oil and lard mixed oil with different melting points according to the palm oil content in order of 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, and 90%, heat and melt , mix and stir evenly, measure the SFC of the two raw material oils and the blended oil and make an isotherm curve. The closer the isotherm curve is to a straight line, the better the compatibility. According to the analysis, the compatibility between lard and palm stearin (45°C) is the best. but if figure 1 As shown, the overall compatibility of lard and palm stearin is still not ideal.

Embodiment 2

[0033] Embodiment 2: the ternary mixture regression experiment of lard and palm oil

[0034] It has been found through research that the incompatibility of two oils is often improved by adding a third oil. Therefore, palm oil fractionation products with different melting points were added to lard and palm stearin in order to improve the compatibility. Through the mixed material regression design experiment, the formula table of each raw material oil in the ternary system was obtained. Weighed lard, palm stearin, and 10 g of the mixed oil of the second palm oil according to the ratio in the table, heated and melted, and mixed and stirred evenly. Measure the SFC value of raw oil and blended oil.

Embodiment 3

[0035] Embodiment 3: The ternary compatibility analysis experiment of lard and palm oil

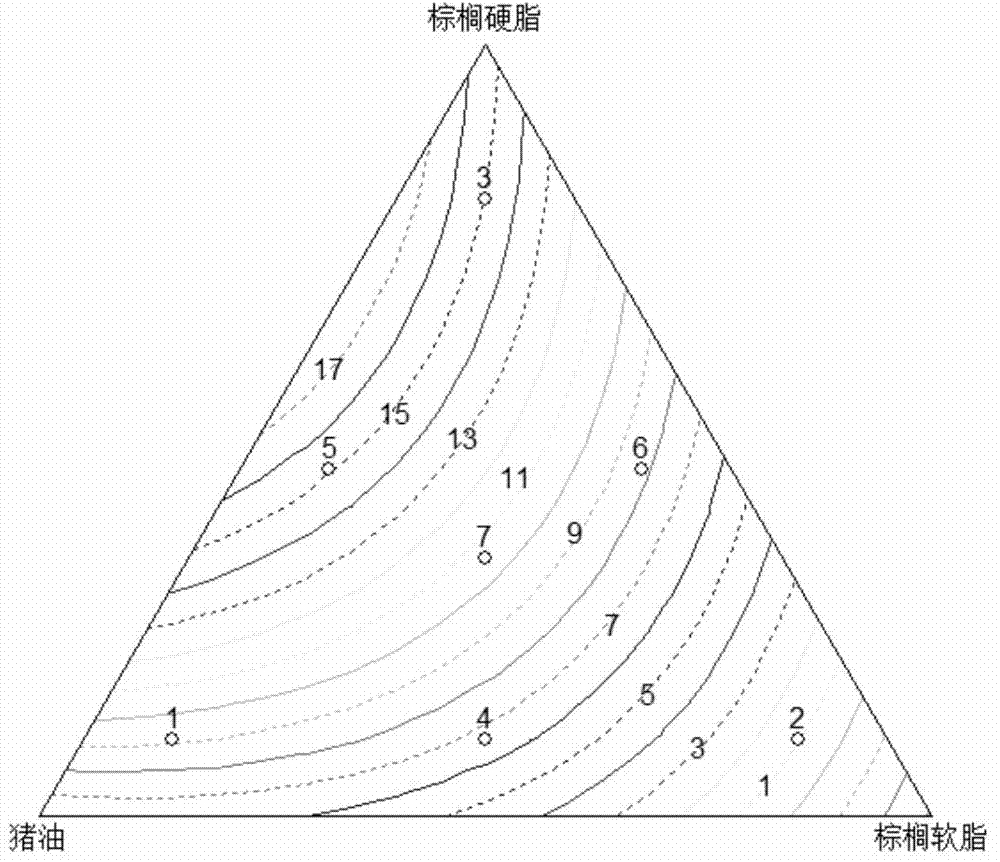

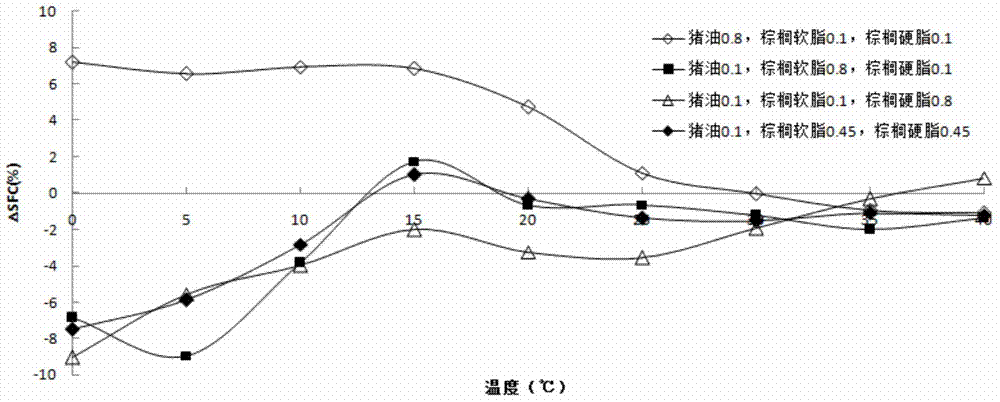

[0036] SFC is the solid fat content in the mixture, which affects many properties of the product such as shape retention, packability, sensory properties, ductility and resistance to oil segregation. The isosolid curve of the ternary system was analyzed with Statistica software. Such as figure 2 , image 3 As shown, it can be known that the compatibility of lard and palm stearin is improved after adding palm omitin (21°C). In order to further analyze the compatibility, an appropriate compatibility formula was selected, and the deviation ΔSFC between the measured SFC of the ternary mixture and the calculated SFC of the ideal thermodynamic mixture was calculated. Comprehensively consider the system with better compatibility, lard: palm omitin: palm stearin = 80%: 10%: 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com