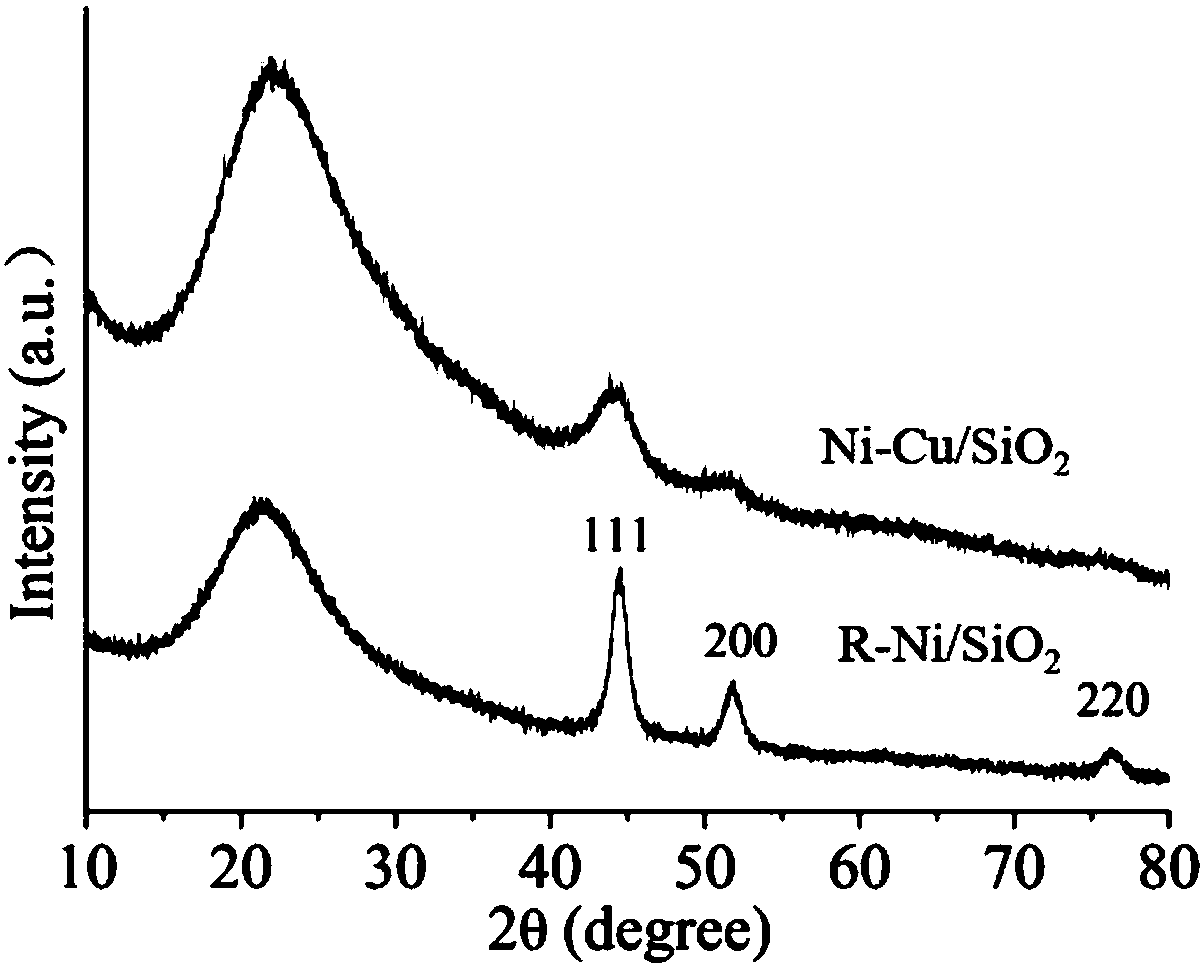

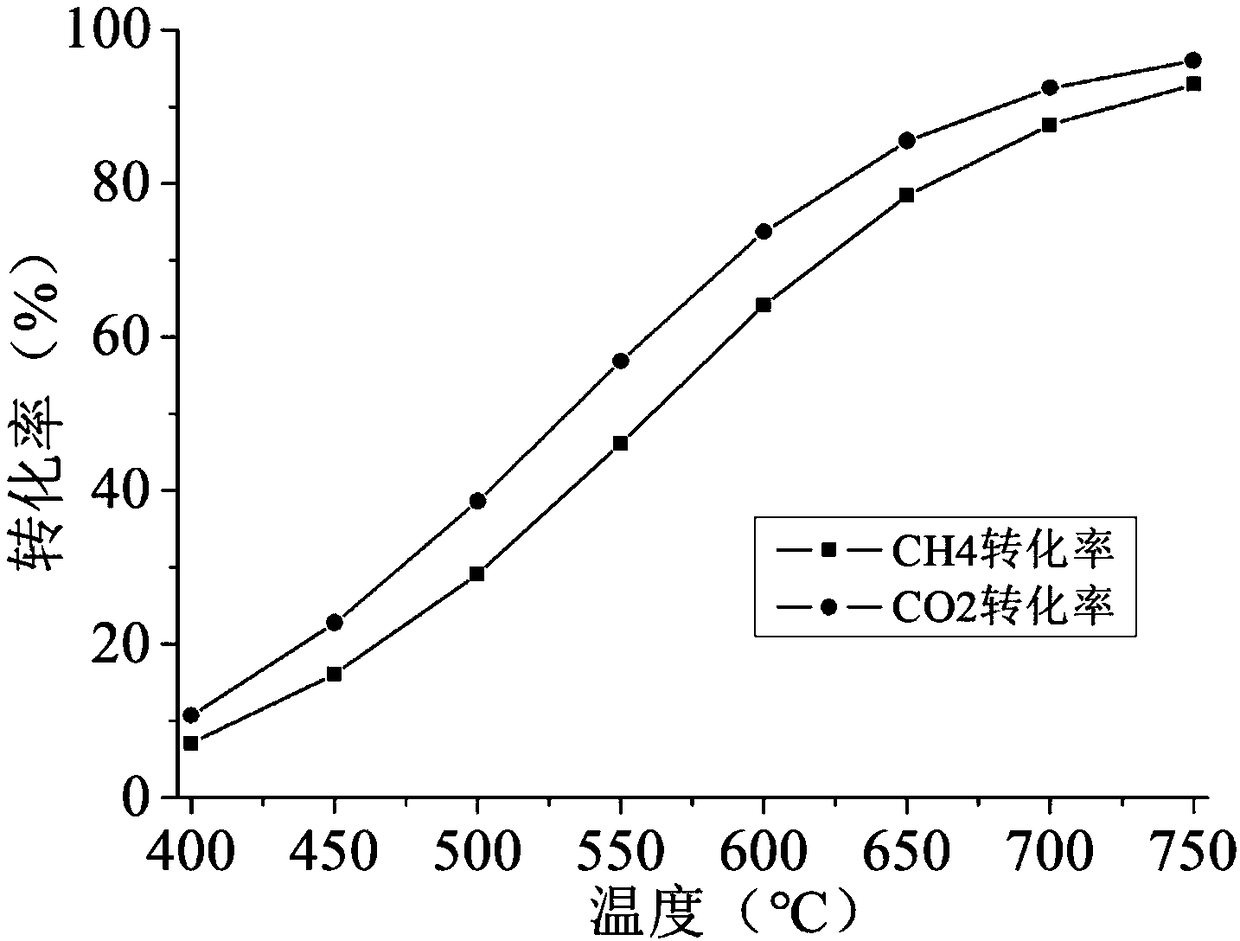

Copper doped Ni/SiO2 nanocomposite catalyst and preparation method thereof

A nano-composite, copper-doped technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. Simple, improved specific surface area, excellent anti-carbon deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A copper-doped Ni / SiO 2 Nano composite catalyst, its preparation method comprises the steps:

[0041] 1) Weigh 25.578g Na 2 SiO 3 9H 2 O was placed in a beaker, and 84.402g of distilled water was added for ultrasonic dissolution to obtain Na 2 SiO 3 solution; dilute analytically pure concentrated nitric acid and distilled water at a volume ratio of 1:4 and add dropwise to the obtained Na 2 SiO 3 In the solution, magnetic stirring is carried out while adding dropwise, until pH=6, and mixed solution I is obtained;

[0042] 2) Weigh 2.617g Ni(NO 3 ) 2 ·6H 2 O was put into a beaker, and 13.833g of distilled water was added for ultrasonic dissolution to obtain a nickel salt solution; 0.2416g Cu(NO 3 ) 2 ·3H 2 O is put into a beaker, and 10 g of distilled water is added for ultrasonic dissolution to obtain a copper salt solution; then the obtained nickel salt solution and copper salt solution solution are added dropwise to the mixed solution I, and magnetic stirring...

Embodiment 2

[0059] A copper-doped Ni / SiO 2 Nano composite catalyst, its preparation method comprises the steps:

[0060] 1) Weigh 25.578g Na 2 SiO 3 9H 2 O was placed in a beaker, and 84.402g of distilled water was added for ultrasonic dissolution to obtain Na 2 SiO 3 solution; dilute analytically pure concentrated nitric acid and distilled water at a volume ratio of 1:4 and add dropwise to the obtained Na 2 SiO 3 In the solution, magnetic stirring is carried out while adding dropwise, until pH=6, and mixed solution I is obtained;

[0061] 2) Weigh 2.7825g Ni(NO 3 ) 2 ·6H 2 O was put into a beaker, and 14.5825g of distilled water was added for ultrasonic dissolution to obtain a nickel salt solution; 0.1208g Cu(NO 3 ) 2 ·3H 2 O is put into a beaker, and 10 g of distilled water is added for ultrasonic dissolution to obtain a copper salt solution; then the obtained nickel salt solution and copper salt solution solution are added dropwise to the mixed solution I, and magnetic stir...

Embodiment 3

[0066] A copper-doped Ni / SiO 2 Nano composite catalyst, its preparation method comprises the steps:

[0067] 1) Weigh 22.736g Na 2 SiO 3 9H 2 O was put into a beaker, and 75.024g of distilled water was added for ultrasonic dissolution to obtain Na 2 SiO 3 solution; dilute analytically pure concentrated nitric acid and distilled water at a volume ratio of 1:4 and add dropwise to the obtained Na 2 SiO 3 In the solution, magnetic stirring is carried out while adding dropwise, until pH=6, and mixed solution I is obtained;

[0068] 2) Weigh 2.617g Ni(NO 3 ) 2 ·6H 2 O was put into a beaker, and 13.833g of distilled water was added for ultrasonic dissolution to obtain a nickel salt solution; 0.2416g Cu(NO 3 ) 2 ·3H 2 O is put into a beaker, and 10 g of distilled water is added for ultrasonic dissolution to obtain a copper salt solution; then the obtained nickel salt solution and copper salt solution solution are added dropwise to the mixed solution I, and magnetic stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com