Method for preparing perovskite nano powder

A nano-powder and perovskite technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of difficult control of stoichiometric ratio of composite perovskite powder, product agglomeration, dispersion of grain size distribution, etc. problem, to achieve the effect of simple and intuitive control method, complete powder crystallization, and concentrated distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

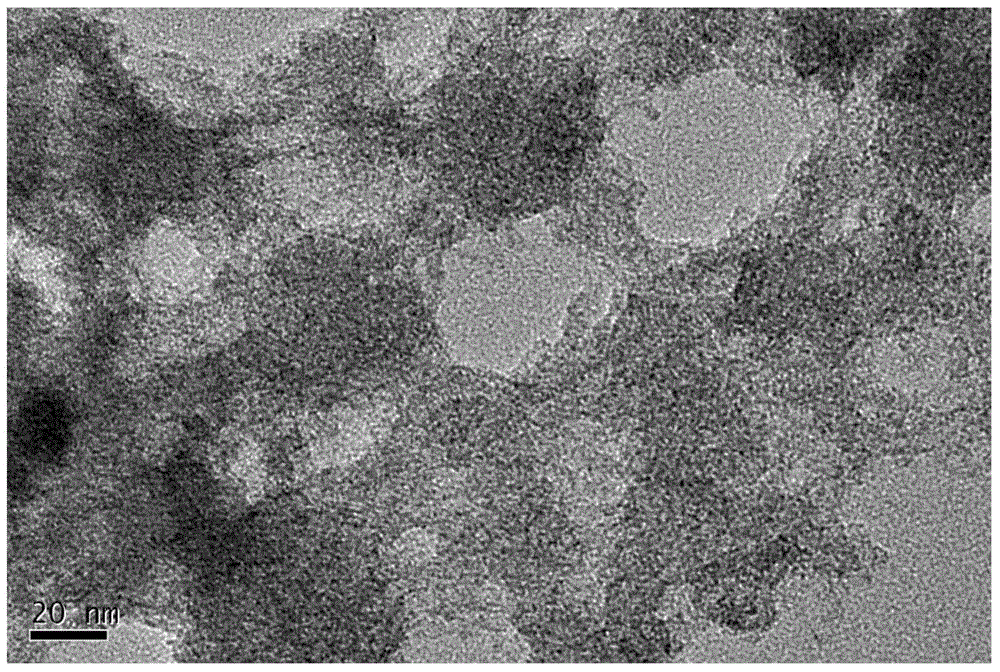

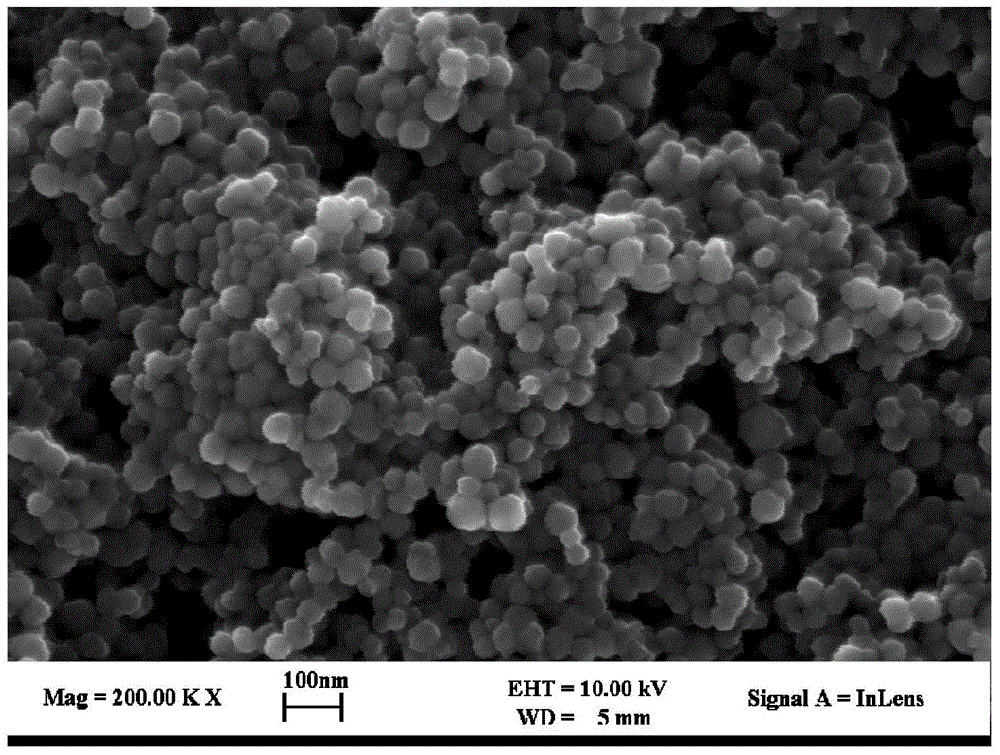

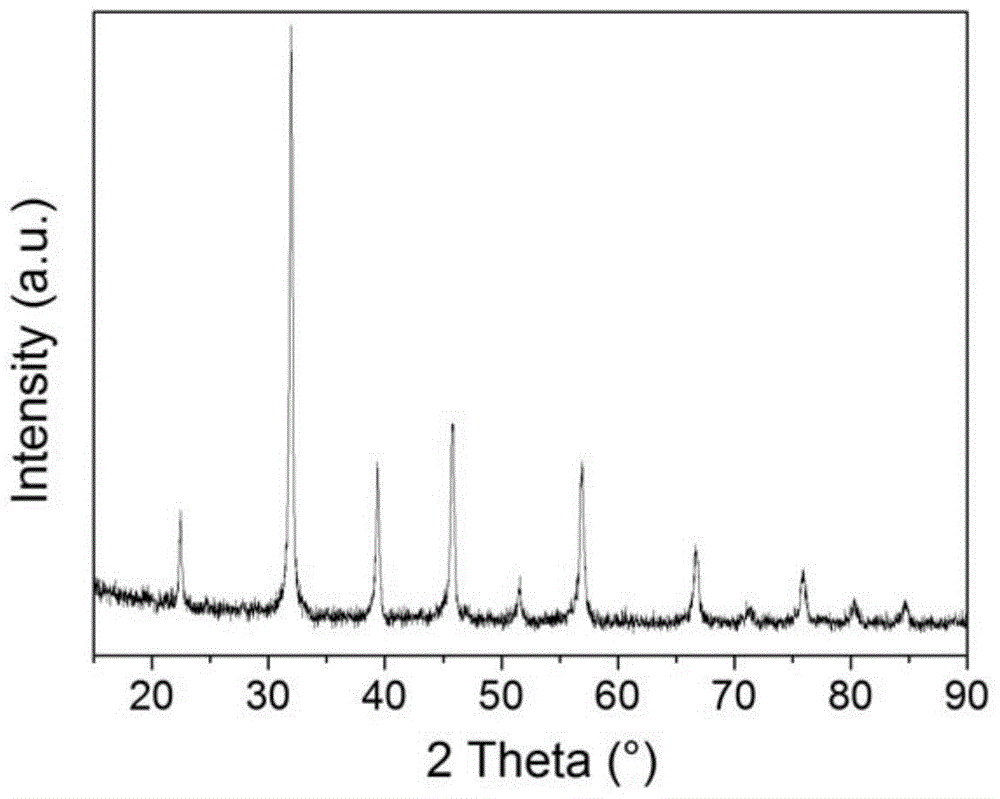

[0046] Example 1, using tetrabutyl titanate as the B-site element source, Ba(OH) 2 ·8H 2 O and Sr(OH) 2 ·8H 2 O is the source of the A-site element, and Ba is prepared 0.6 Sr 0.4 TiO 3 Nanocrystalline powder

[0047] Measure 10ml of absolute ethanol with a pipette and place it in a beaker, weigh 8.5088g of tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) into a beaker and stirred until a clear yellow solution was formed, which was designated as solution A, and was transferred into a separatory funnel; 40ml of deionized water was added to a conical flask, 0.1g of PEG (molecular weight 4000) and 2ml of acetic acid were added, stirred evenly, and recorded Make solution B; slowly add solution A dropwise to solution B under vigorous stirring, keep stirring after the dropwise addition, add 4ml of ammonia water and continue stirring. Then put it in a water bath at 60°C for 1 hour to obtain a gel, and centrifuge to obtain the hydrated TiO required for the atmospheric pressure hydrother...

Embodiment 2

[0054] Example 2, using tetrabutyl titanate and zirconium n-butoxide (commercially available 1-butanol solution of zirconium n-butoxide with a mass fraction of zirconium n-butoxide of 80%) as the B-site element source, Ba(OH) 2 ·8H 2 O is A-site element source to prepare BaZr x Ti 1-x o 3 Nanocrystalline powder

[0055] Measure 12ml of absolute ethanol with a pipette and place it in a beaker, weigh 7.2325g of tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) and 3.2499g of zirconium n-butoxide in 1-butanol solution were added to the beaker, stirred until a clear yellow solution was formed, which was recorded as solution A, and moved into a separatory funnel; 50ml of deionized water was added to a conical flask, and 0.15g PEG (molecular weight 2000) and 3ml acetic acid, stir evenly, record as solution B; under the condition of vigorously stirring solution B, slowly add solution A to solution B, keep stirring after the addition, and slowly use a separatory funnel Add 5ml of ammonia ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com