Method for preparing high-quality molybdenum disulfide thin films with layer numbers being uniform

A molybdenum disulfide, high-quality technology, applied in the field of nanomaterials, can solve the problem of uneven size of molybdenum disulfide, achieve the effect of precise control of process parameters, conducive to repeated tests, and simple addition methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

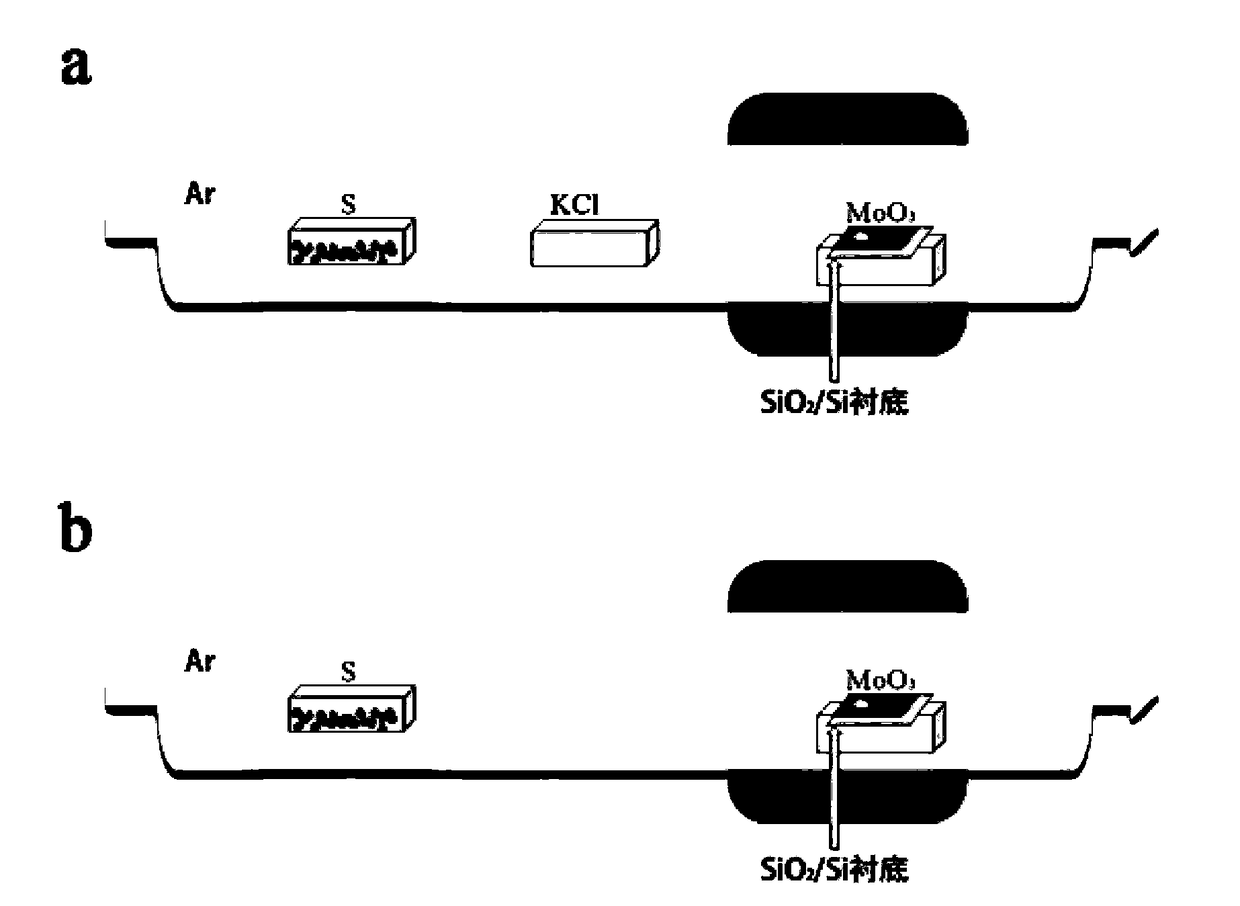

[0037] This example provides a method for using potassium chloride to assist in the preparation of a large-area and high-quality molybdenum disulfide film with good uniformity. The experimental schematic diagram is as follows figure 1 As shown in (a), the experimental process includes the following steps:

[0038] Step 1): First use the acetone / carbon tetrachloride mixed solution and absolute ethanol to perform ultrasonic cleaning on the silicon dioxide / silicon substrate in this order, each process lasts 30 minutes, and the acetone / carbon tetrachloride mixed solution The function is to remove the grease on the surface of the copper sheet. Ethanol is an effective dispersant, which can clean and disperse the soluble impurities and residual acetone on the surface of the silicon dioxide / silicon substrate, and then use deionized water to obtain a clean SiO2 / Silicon Substrate.

[0039] Step 2): Prepare 20ml of "piranha" solution, in order to completely remove organic impurities on ...

Embodiment 2

[0045] This comparative example provides a kind of auxiliary preparation method of molybdenum disulfide thin film that reduces potassium chloride consumption, comprises the following steps,

[0046] Step 1): The method for cleaning the substrate in Embodiment 1 is the same.

[0047] Step 2), is identical with embodiment one.

[0048] Step 3): Weigh 120mg of pure sulfur powder, 5mg of potassium chloride and 0.5mg of molybdenum trioxide respectively, place the pure sulfur powder in the upstream position of the quartz tube of the tubular atmosphere furnace, place the molybdenum trioxide powder in the cleaning Put the clean silicon dioxide / silicon substrate on the heating center of the tubular atmosphere furnace, put potassium chloride between the silicon dioxide / silicon substrate and pure sulfur powder, potassium chloride and silicon dioxide / silicon lining The distance between the bottoms is 6 cm.

[0049] Step 4): same as embodiment two.

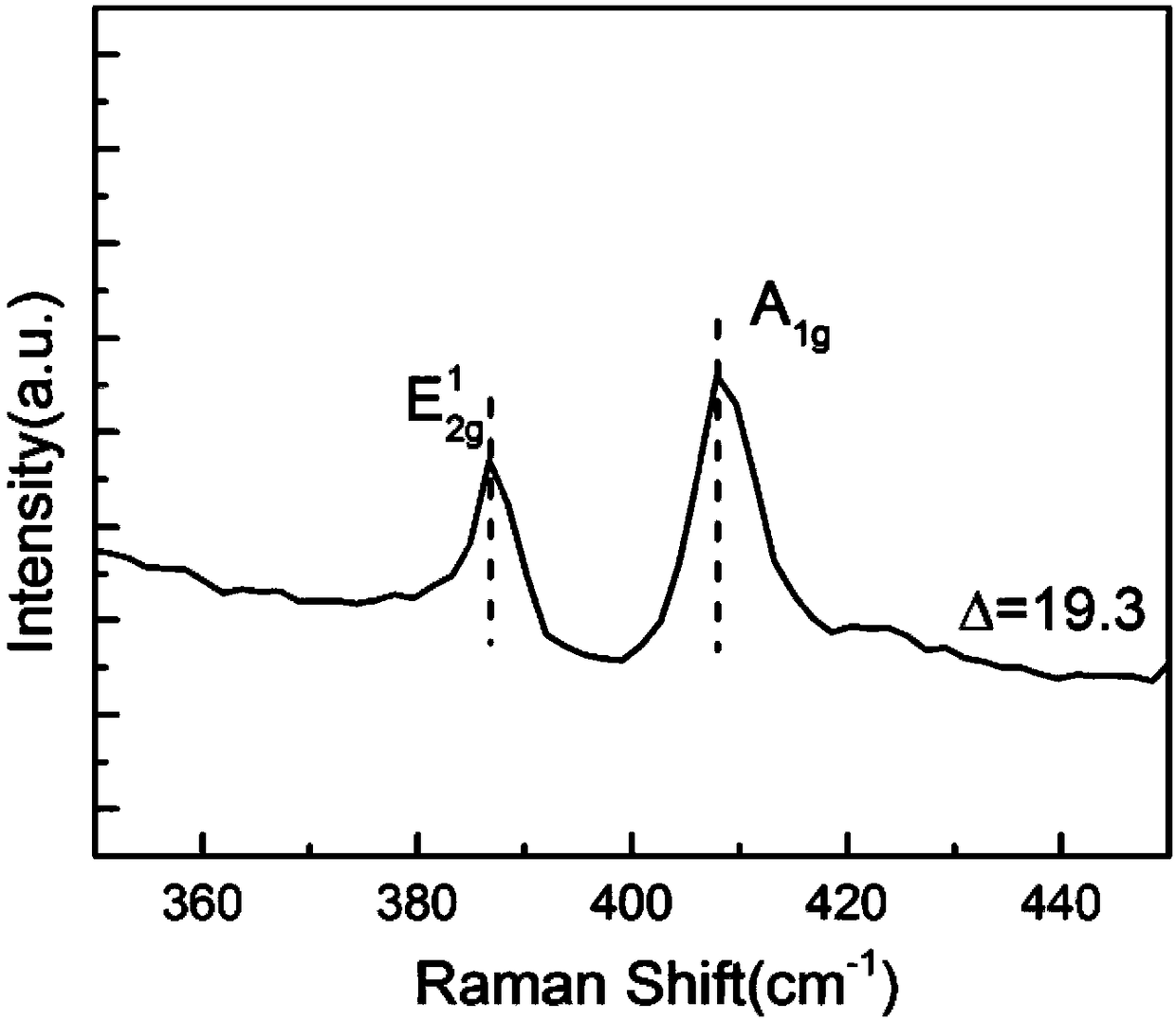

[0050] Figure 4 In order to prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com