Patents

Literature

85results about How to "Precise control of process parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene-reinforced titanium-based nanocomposite material and preparation method

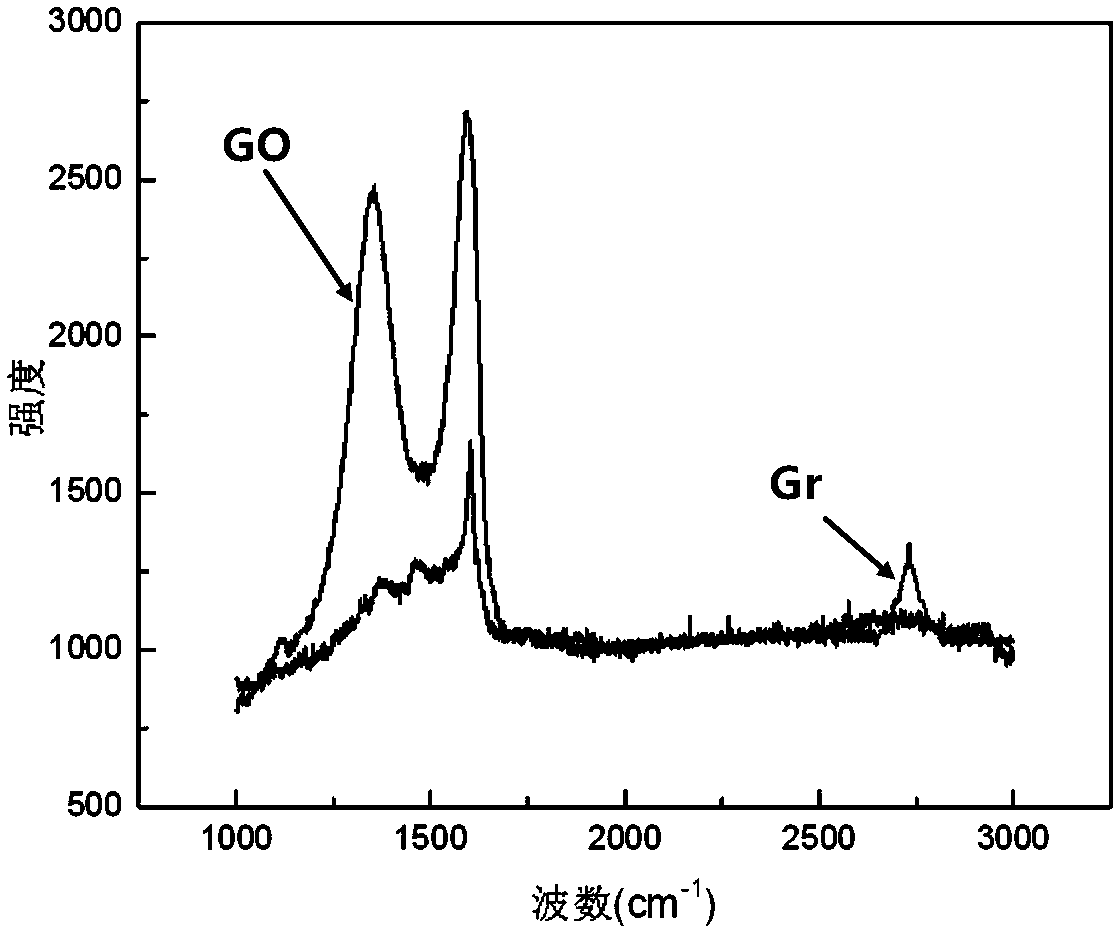

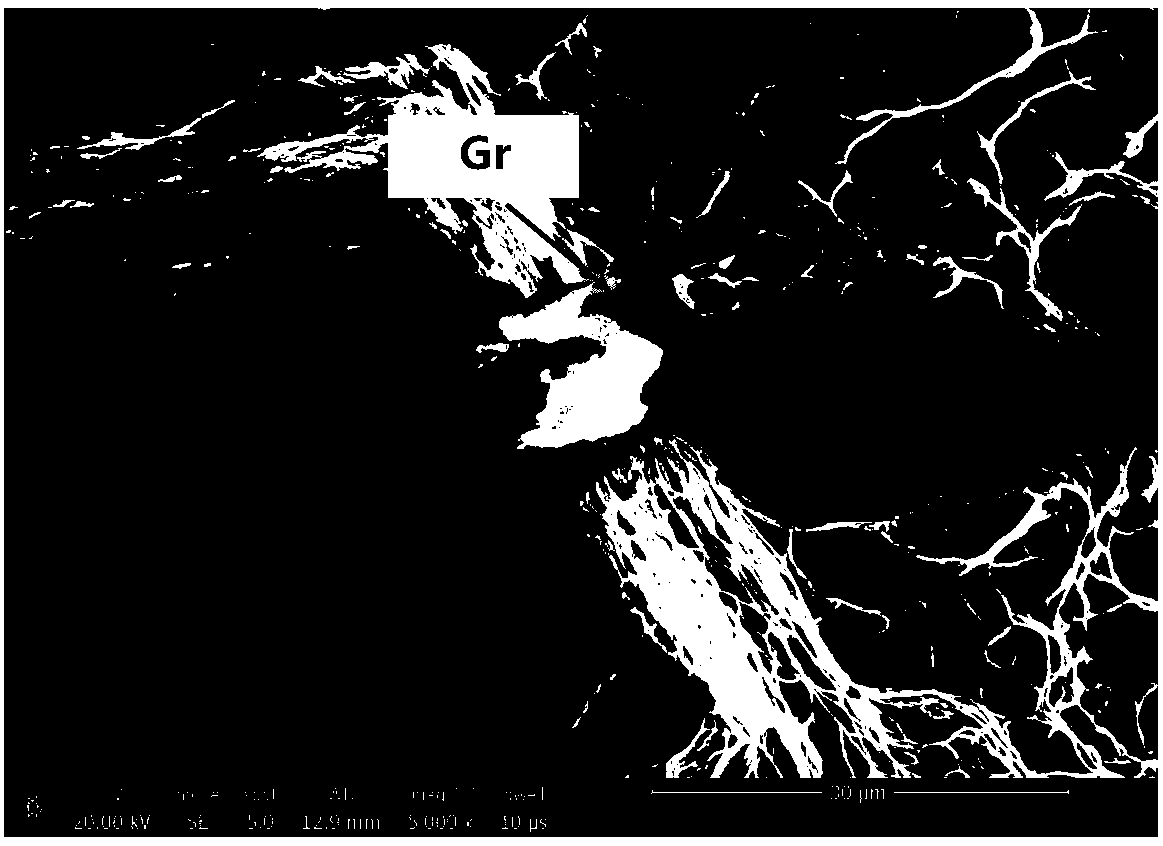

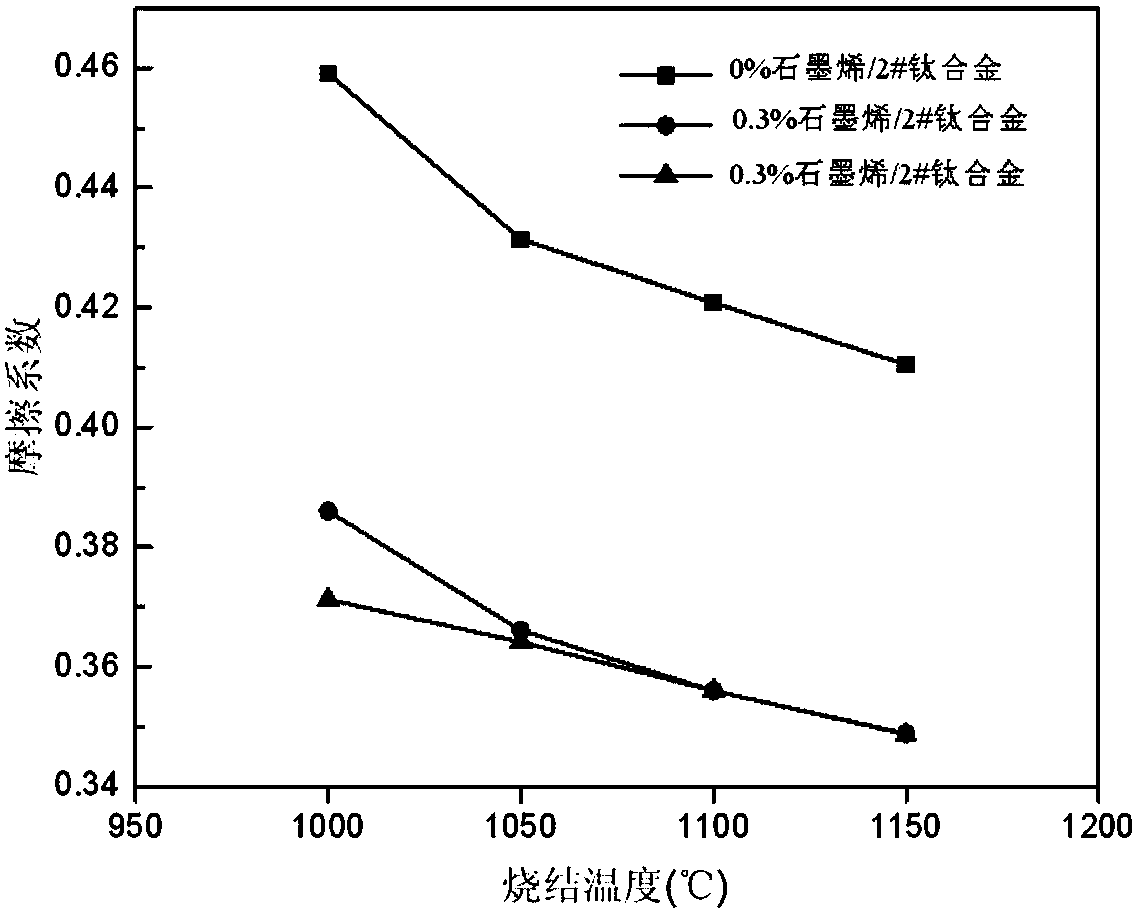

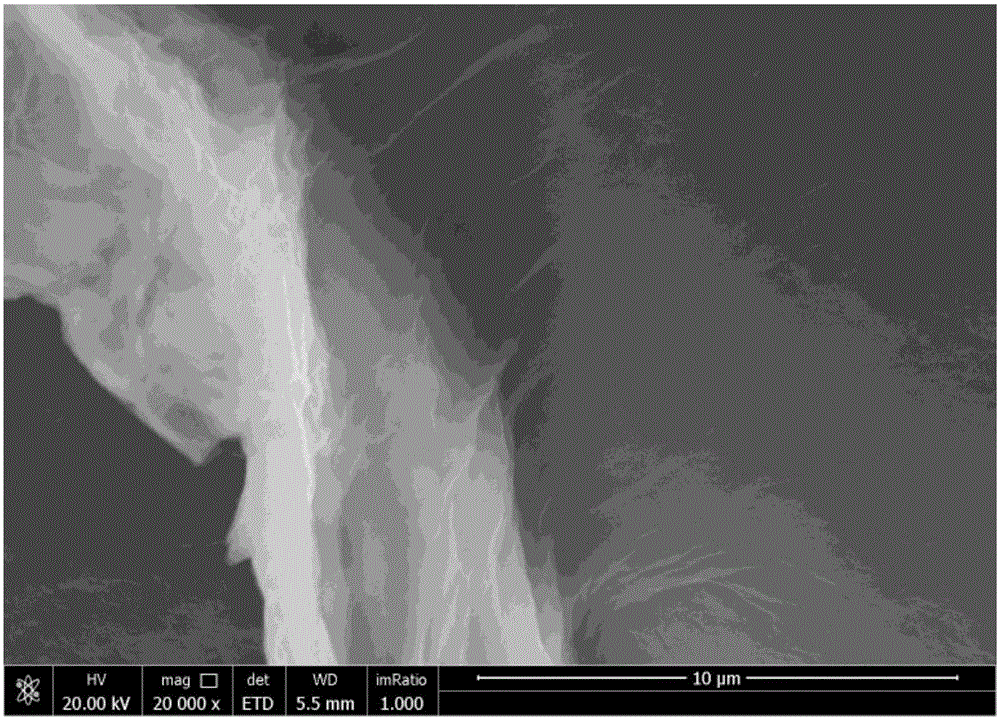

The invention belongs to the technical field of graphene composite materials and relates to a titanium-based nanocomposite material reinforced through graphene and a preparation method, in particularto a graphene-reinforced titanium-based nanocomposite material and a preparation method. Firstly, oxidized graphene nanosheets of 0.01 wt%-1.0 wt% of titanium alloy powder are weighed to be added intoabsolute ethyl alcohol to be stirred and mixed, then disperse treatment is conducted through an ultrasonic cell pulverizer, and an oxidized graphene solution is prepared; then the titanium alloy powder with the alloying element content being larger than 10 wt% and the oxidized graphene solution are stirred and mixed under inert protection, and oxidized graphene and titanium alloy powder compositepowder is obtained; and finally, the composite powder is loaded into a graphite mold to be sintered, through vacuum pumping and sintering forming, oxidized graphene is basically decomposed to form graphene, and therefore the graphene-reinforced titanium-based nanocomposite material with the excellent mechanical property is prepared. In the graphene-reinforced titanium-based nanocomposite material, the graphene is uniformly dispersed, and the preparation method is simple, efficient and suitable for batch preparation.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

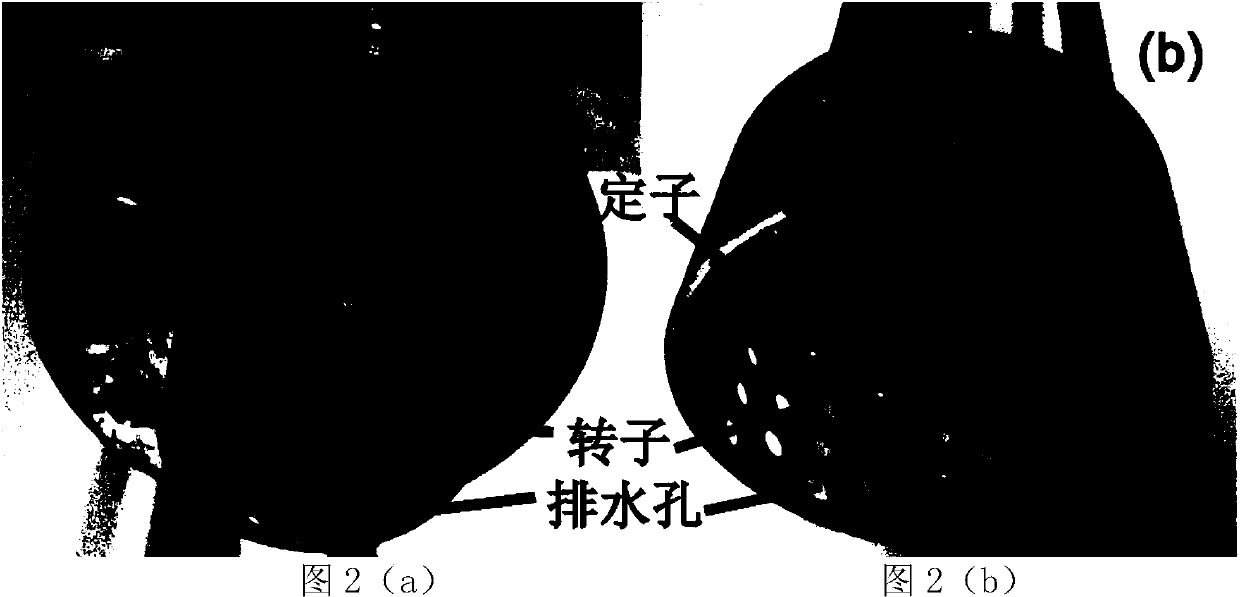

Preparation method for small-size graphene

ActiveCN104003375AHigh monolayer ratioAvoid destructionMaterial nanotechnologyGrapheneCentrifugationGraphite

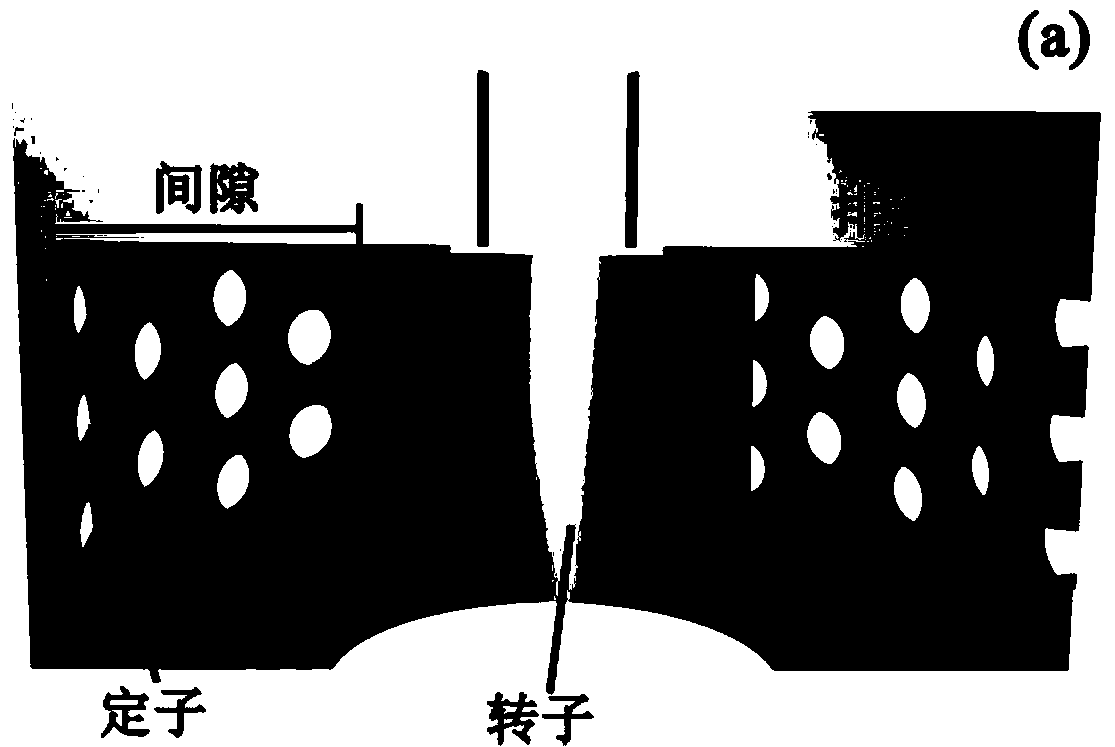

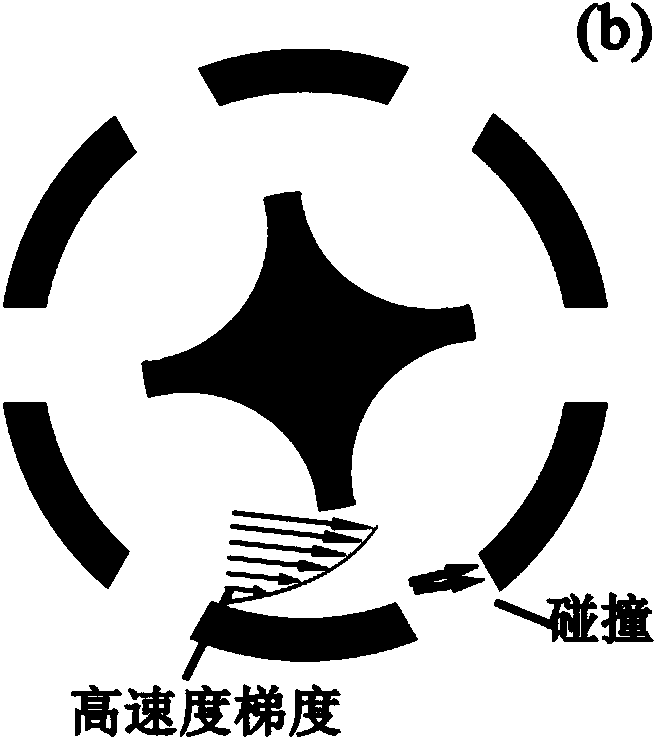

A disclosed preparation method for small-size graphene comprises the steps: step 1, mixing a graphite powder raw material and a solvent to obtain a graphite mixed solution; step 2, putting the solution in a container, and fixedly arranging a homogenizing head of a stator-rotor apparatus of a stator-rotor mixer below the liquid level; step 3, starting a cooling system and the stator-rotor mixer for processing; and step 4, performing standing processing or centrifugation separation on the prepared solution to remove incompletely-peeled particles, and collecting the supernatant to obtain a stable dispersion solution of small-size graphene. According to the preparation method, a rotor rotating with a high speed drives a fluid to have a high-speed motion, so that high velocity gradient and high shear force are generated, and also graphite sheets are subjected to peeling and refining because the high-speed fluid bumps bosses of a hole wall of a stator, and the prepared graphene is small in dimension, concentrated in distribution and high in single-layer ratio. The method has the characteristics of small equipment investment, low raw material cost, simple, easy and practicable operation and impressive output, and is suitable for large-scale industrialized production as well as laboratory research.

Owner:BEIHANG UNIV

Nanopore array film on stainless steel surface and preparation method thereof

InactiveCN102268713ALess investmentLow priceMaterial nanotechnologyAnodisationElectrochemical anodizationElectrochemistry

The invention particularly relates to a stainless steel surface nano-pore array film and a preparation method thereof. The technical scheme is that: stainless steel treated by surface pretreatment is used as an anode and is placed in a phosphate buffer solution to perform electrochemical anodic oxidation treatment; the time for the electrochemical anodic oxidation treatment is 0.1-4 h; a nano-pore array film is obtained on the treated stainless steel surface; the voltage for the electrochemical anodic oxidation is 10-80 V, and the temperature for the electrochemical anodic oxidation is -5 to 40 DEG C. The preparation method of the invention is simple, effective, environment-friendly, and low in cost; the stainless steel surface nano-pore array prepared by the method has a structured and ordered structure, a high density, a controllable pore diameter and pore depth, and no other impurity elements intervened, is firmly combined with the substrate, and has strong corrosion resistance andhigh hardness.

Owner:WUHAN UNIV OF SCI & TECH

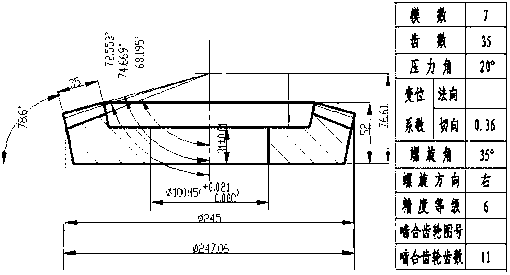

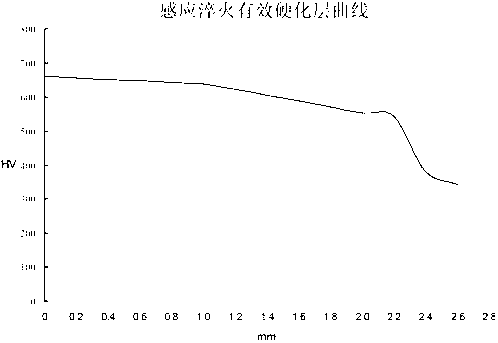

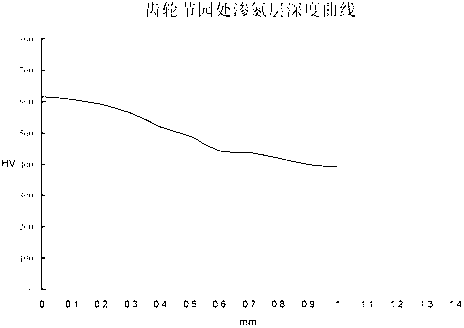

Anti-fatigue manufacturing method of spiral bevel gear

The invention relates to a novel composite surface-enhanced spiral bevel gear production process system based on a current anti-fatigue manufacturing method system and integrating induction quenching and gas nitriding. The invention aims to provide a composite surface-enhanced cyclo-palloid spiral bevel gear manufacturing method with heated precision of 4 to 6 levels and achieving the purpose that the theory contact zone meshed strength is meshed with carburizing and quenching strength. The invention aims to further provide a new spiral bevel gear production technology which can not only embody the current anti-fatigue high-end gear manufacturing method purpose, but also agree with the complete software and hardware match of a roadmap of heat treatment technology development in China.

Owner:天津市天瑞硬化工程有限公司

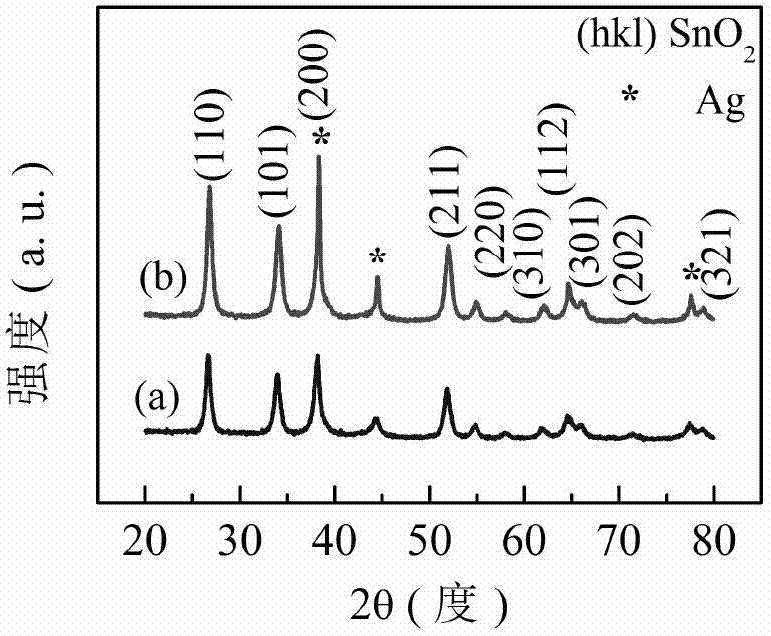

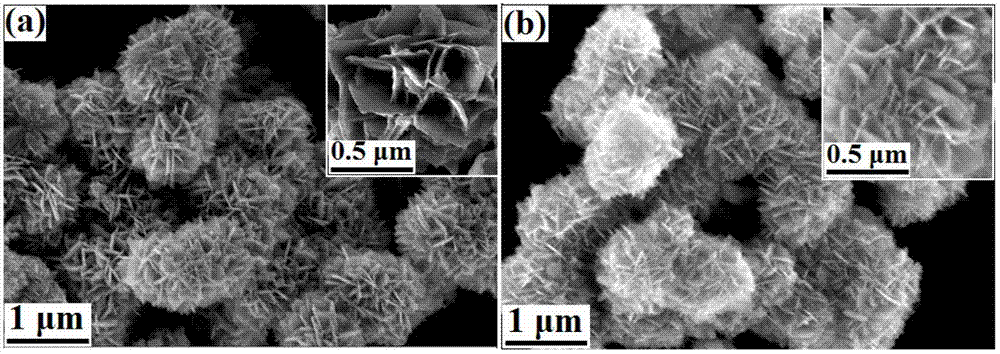

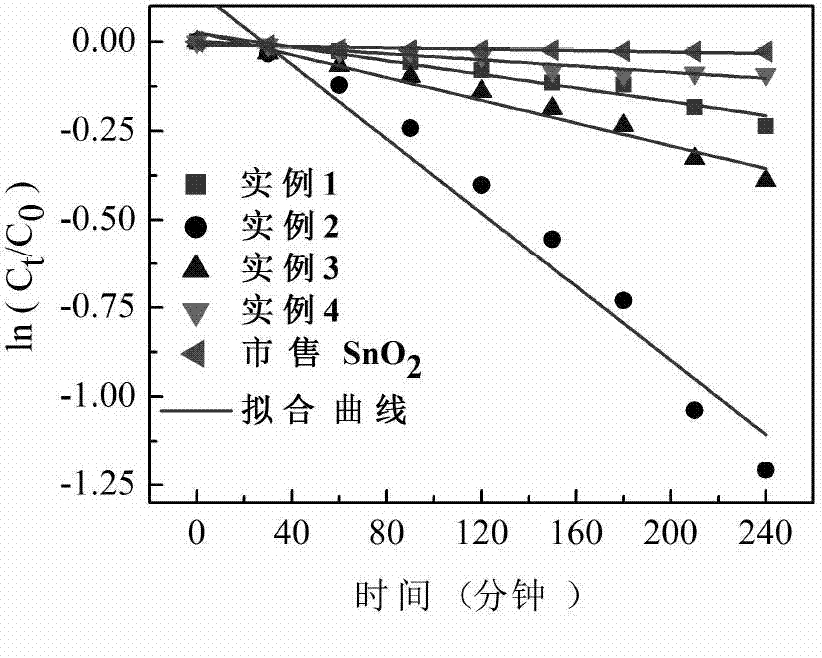

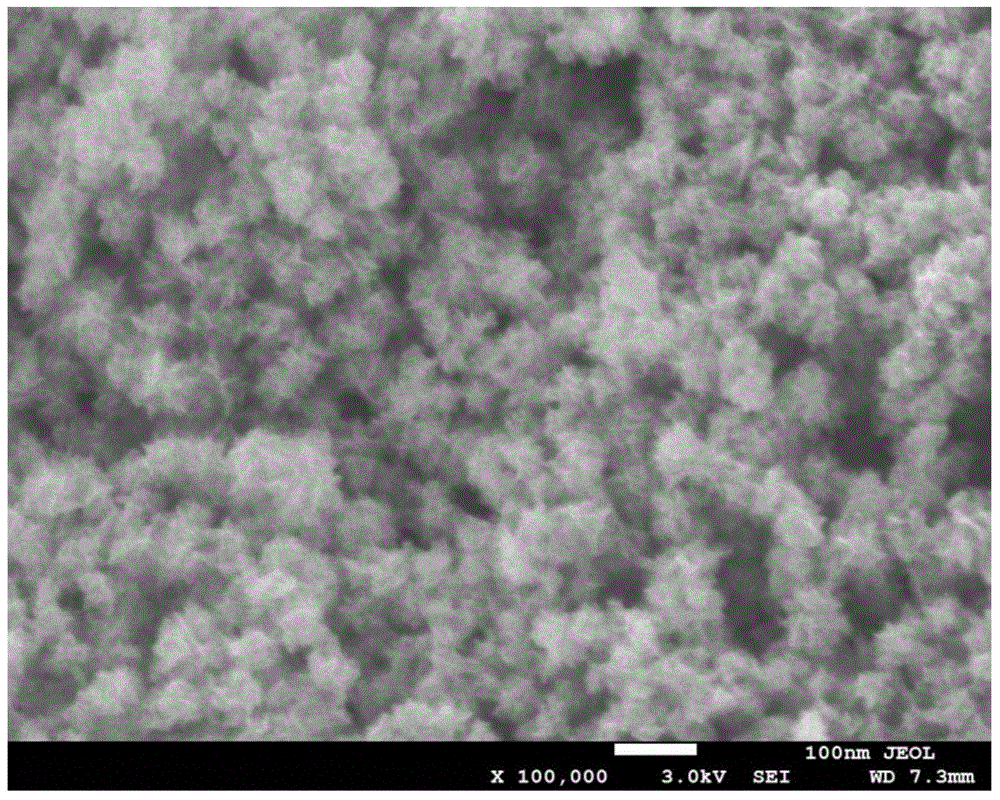

Preparation method of flower-like tin oxide/silver heterojunction material

InactiveCN102764652AHigh crystallinityShort manufacturing cycleMetal/metal-oxides/metal-hydroxide catalystsTin dioxideHeterojunction

The invention discloses a preparation method of a flower-like tin oxide / silver heterojunction material. The method is used for solving the technical problem that the preparation period of preparation of the metal silver doped with stannic oxide is long. The technical scheme includes that a mixed solution of SnC12.2H20 and Na3C6H5O7.2H2O is prepared firstly, flaky NaOH is added, the mixture is mixed uniformly, the prepared AgNO3 solution is added to the mixed solution, the mixed solution is transferred to a reaction tank and added into a microwave reactor for heating, the temperature is lowered to a room temperature after the reaction, the solution in a reaction container is poured out, performing repeat washing with deionized water and absolute ethyl alcohol and drying after filtering, the temperature is raised to 450-600 DEG C with the speed of 1-3 DEG C min-1, 1-2.5 h heat preservation is achieved, and the flower-like tin oxide / silver heterojunction material is obtained. Microwave water heating is performed, and a heat processing method is supplemented, so that flower-like tin oxide / silver heterojunction which is in good crystallinity is obtained, the preparation period is shortened, and the technological parameter can be controlled accurately.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

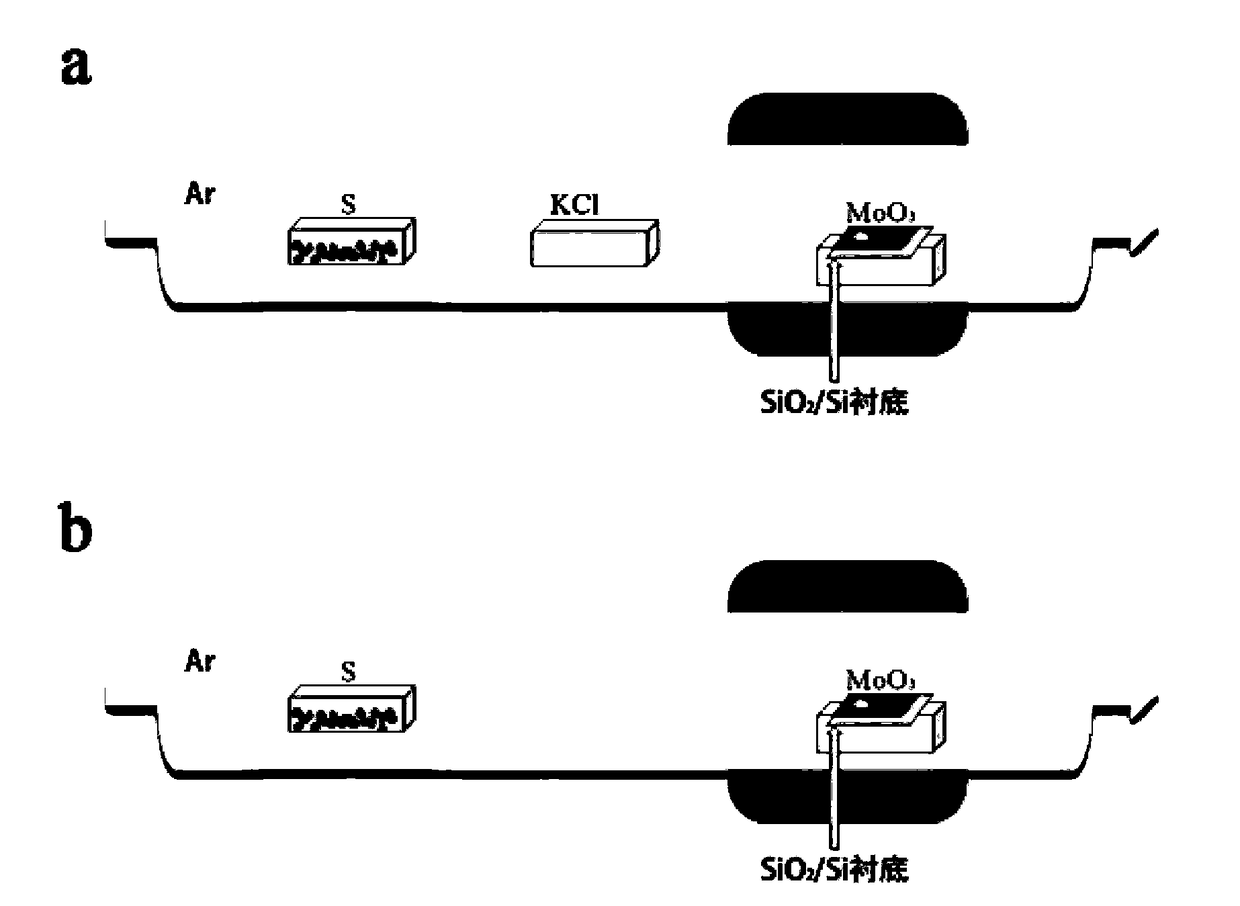

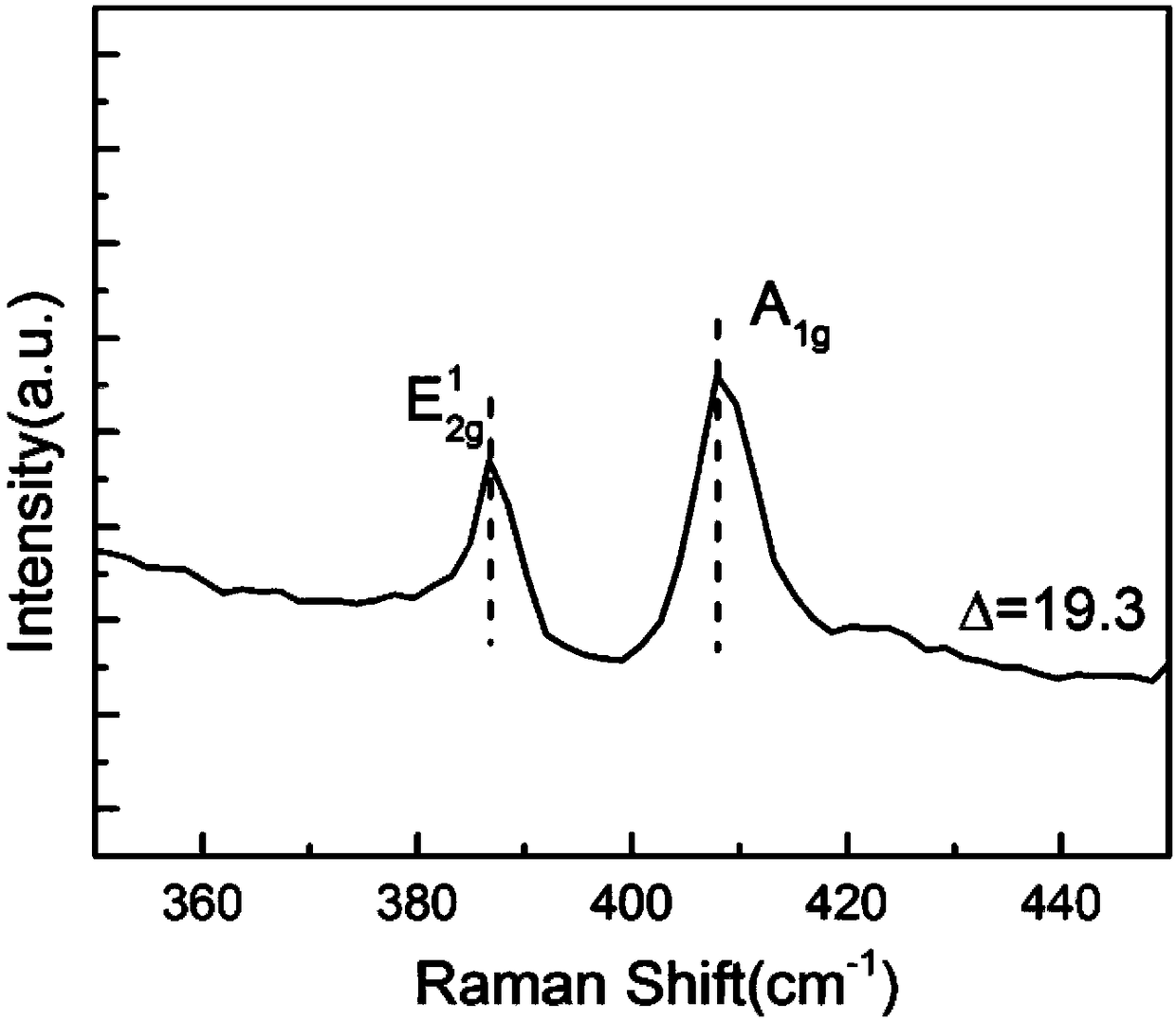

Method for preparing high-quality molybdenum disulfide thin films with layer numbers being uniform

InactiveCN108286042AEasy to addGood repeat testChemical vapor deposition coatingPotassiumSilicon dioxide

The invention discloses a method for preparing high-quality molybdenum disulfide thin films with the layer numbers being uniform. Potassium chloride is used for assisting a chemical vapor deposition method in preparing of large-area single-layer molybdenum disulfide thin films on a silicon substrate covered by a silicon dioxide layer with the thickness being 300nm, and the single-layer molybdenumdisulfide thin films of different dimensions can be obtained by controlling the amount of different sorts of the potassium chloride. The method has the advantages that the high-quality molybdenum disulfide thin films with good homogeneity can be effectively prepared through the potassium chloride, and the experimental method is simple in technology, low in cost and suitable for mass production; the prepared molybdenum disulfide thin films can be used as two-dimensional transparent semiconductor films to be applied to the fields of photoelectric devices, flexible and transparent devices, optical detectors and the like; and the method is of high application value and significance to electronic material preparation and production.

Owner:NORTHWEST UNIV(CN)

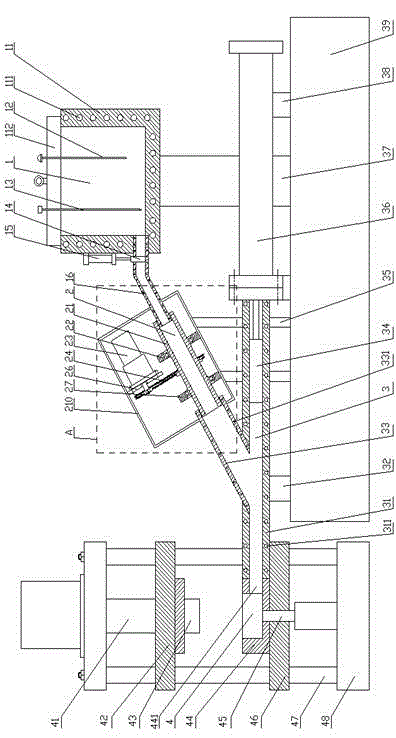

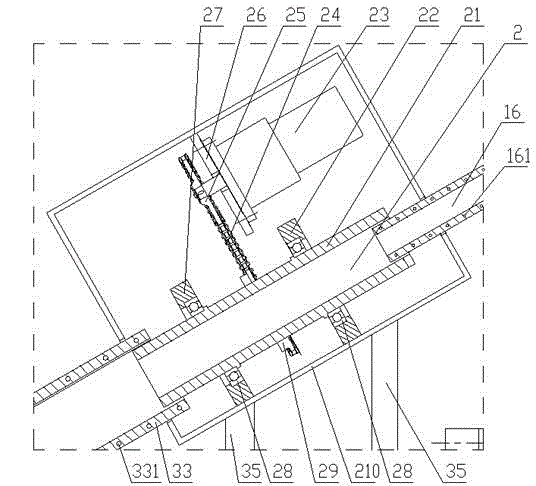

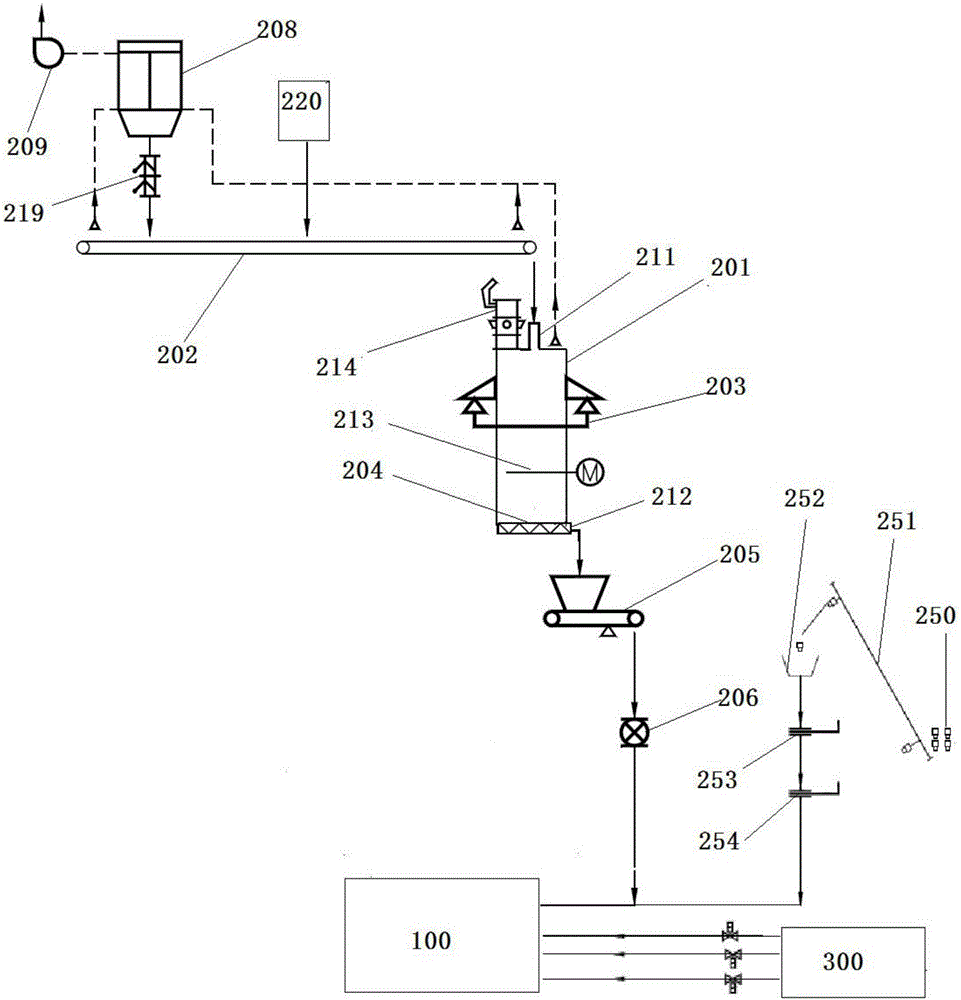

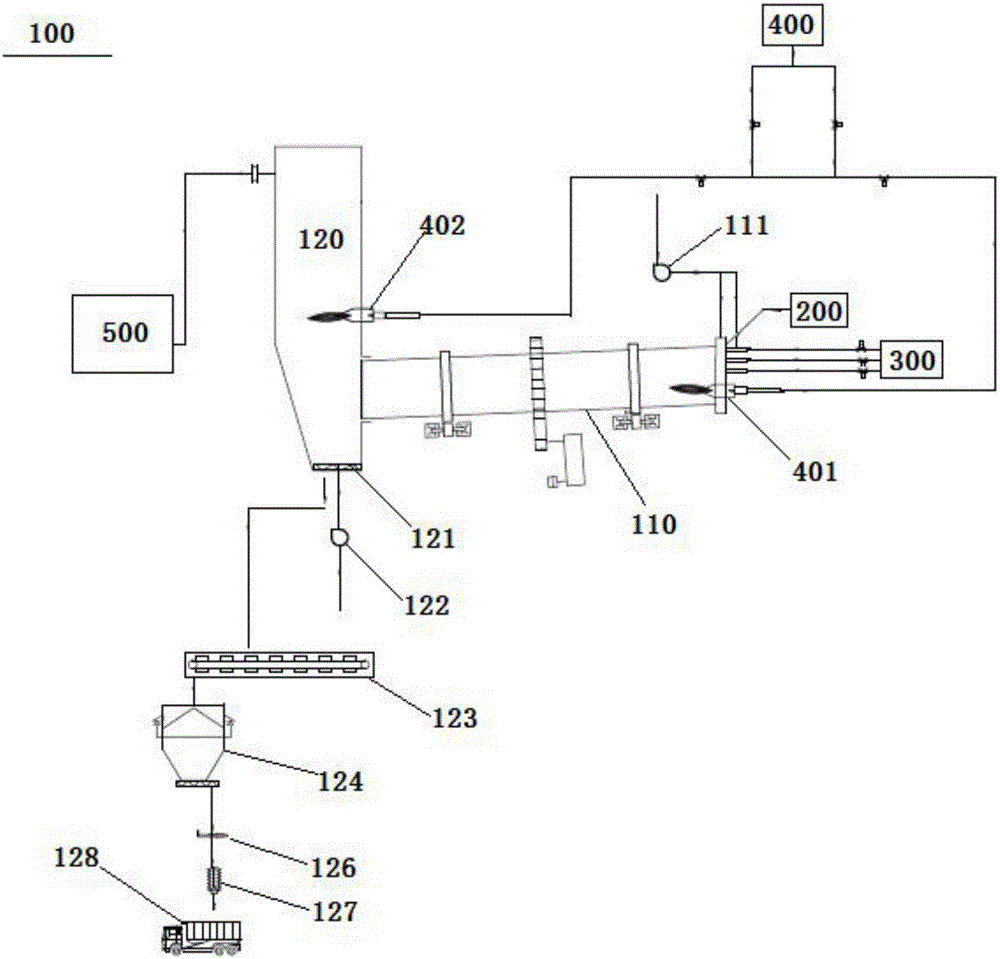

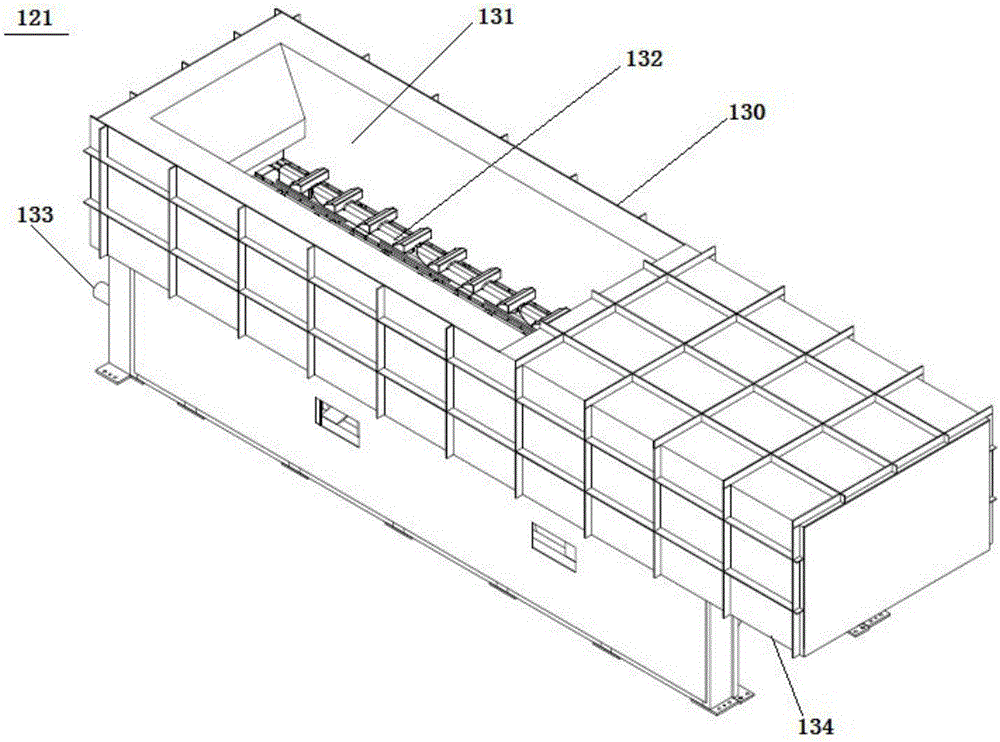

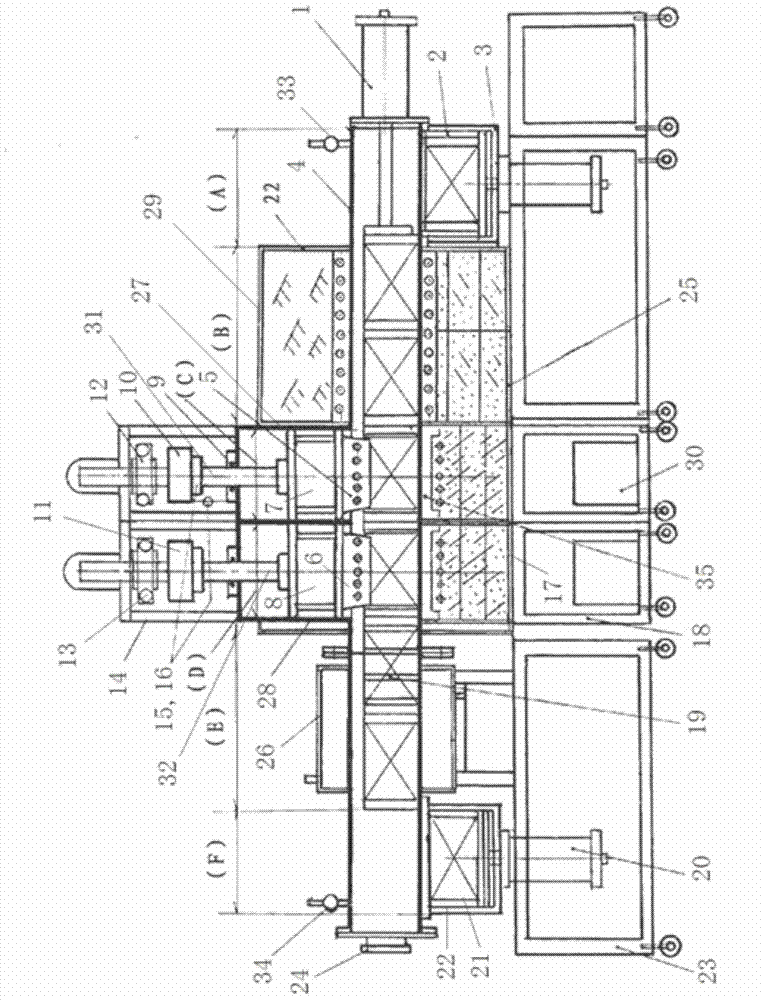

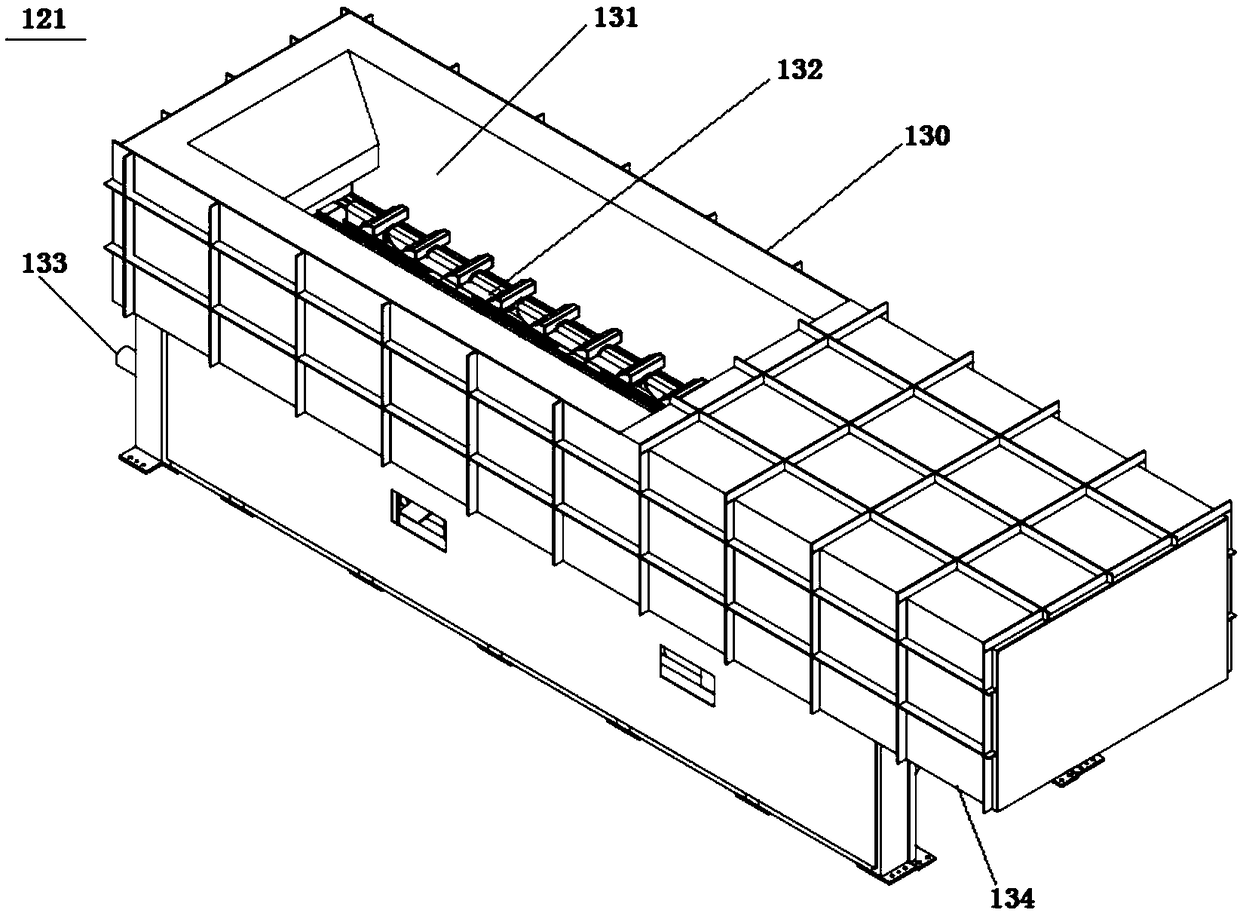

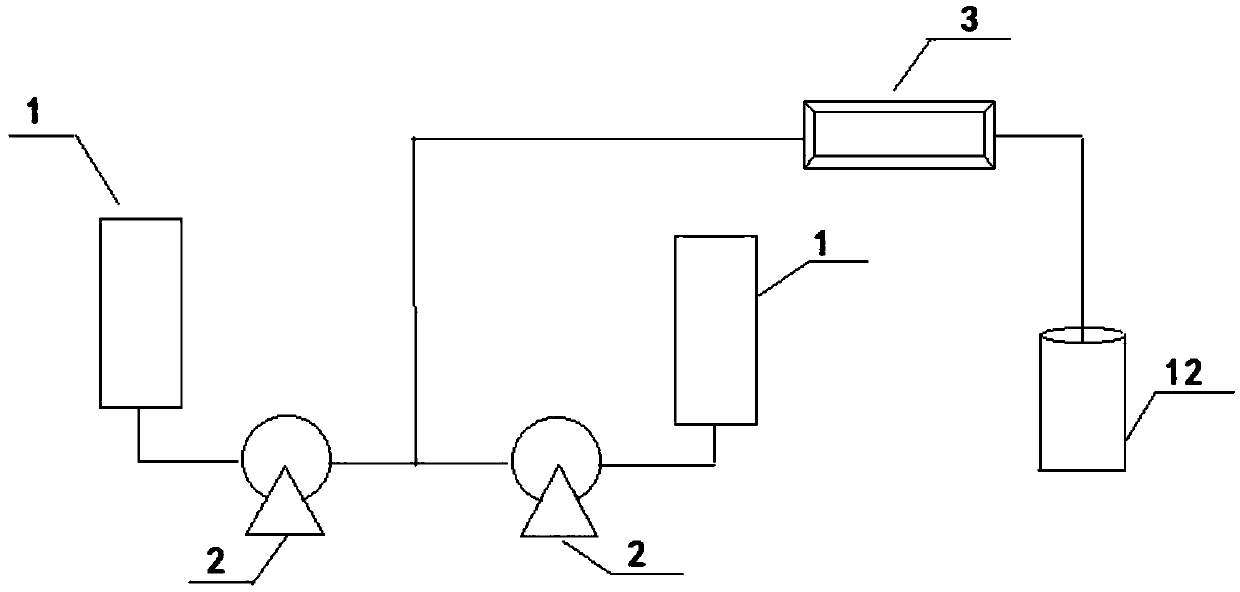

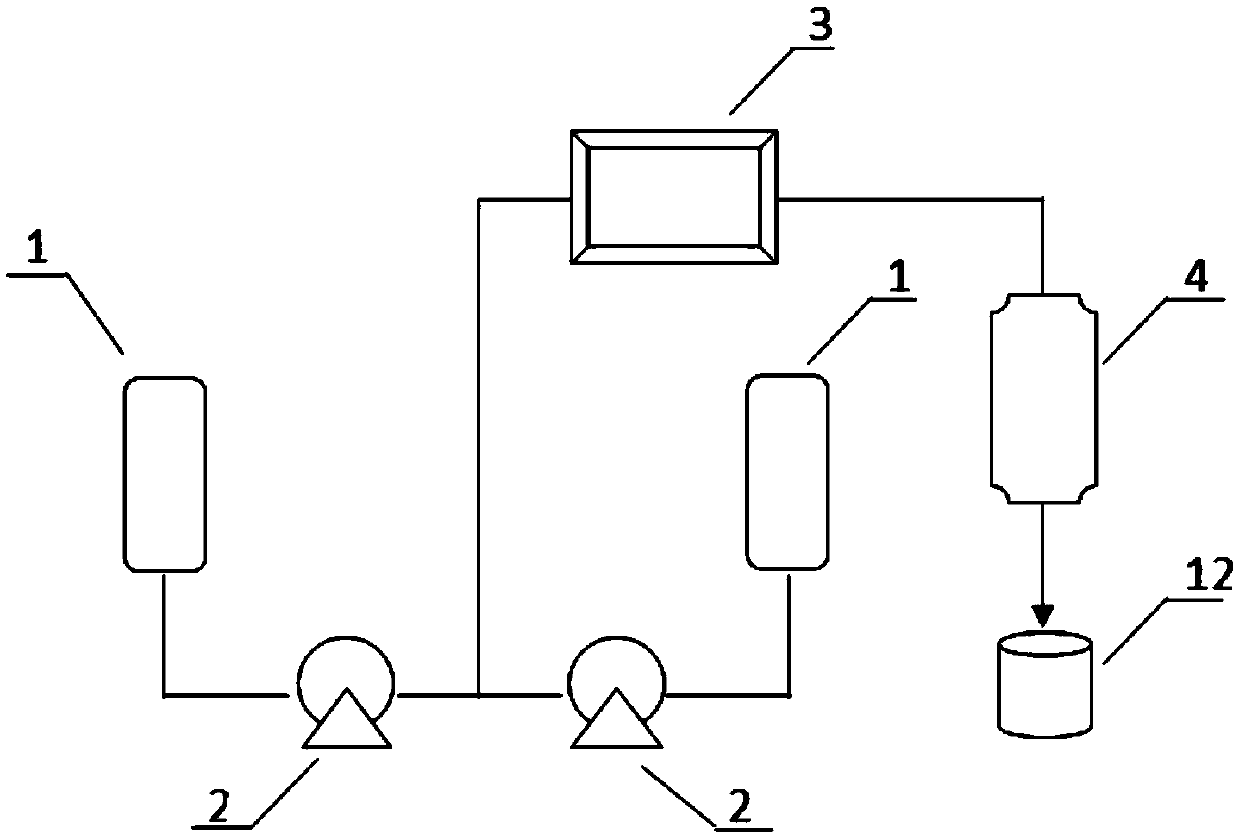

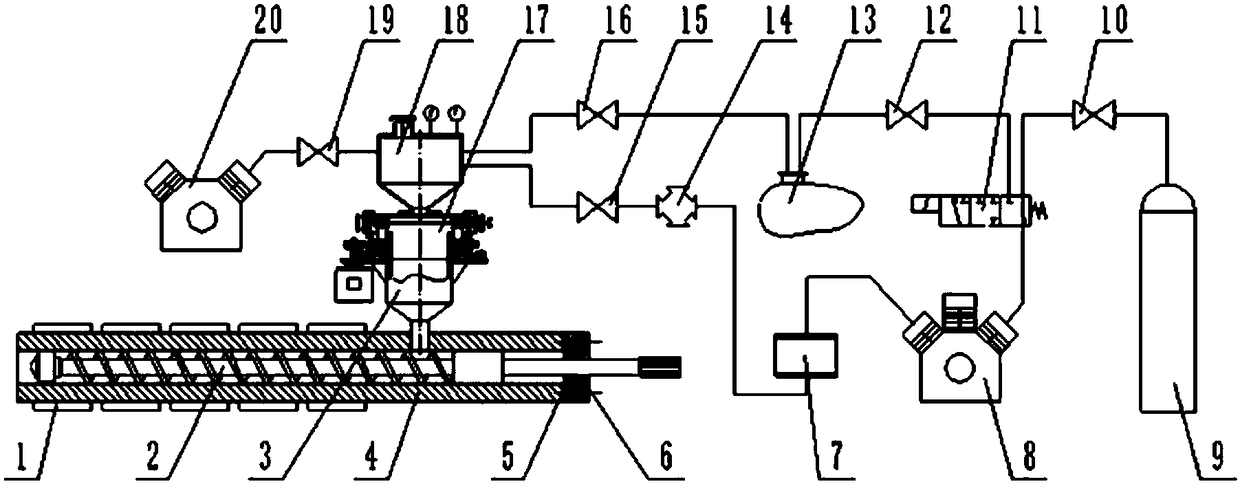

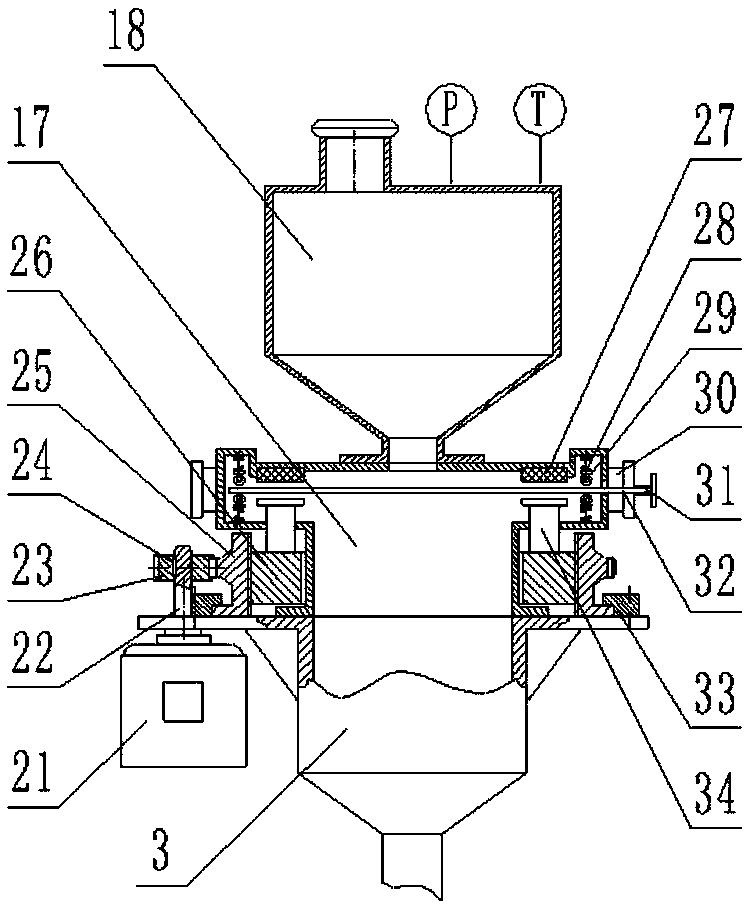

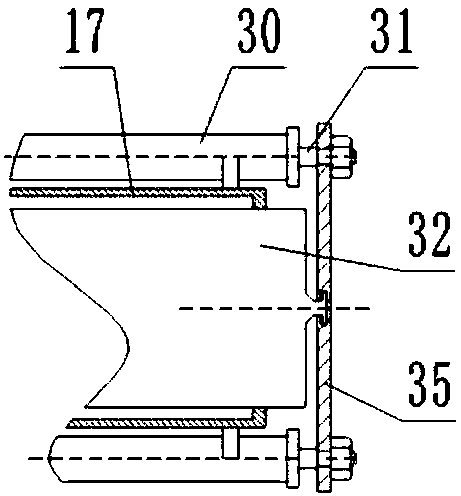

Semi-solid state machining and integrating system

The invention discloses a semi-solid state machining and integrating system. The semi-solid state machining and integrating system is characterized by comprising a melting furnace component (1), a slurry preparation component (2), a mold material injection component (3) and an extrusion forming machine component (4); the slurry preparation component (2) is connected with the melting furnace component (1) through an upper diversion pipe (16), and is connected with the mold material injection component (3) through a lower diversion pipe (33); the mold material injection component (3) is connected with the extrusion forming machine component (4) through a mold material injection channel (31). According to the semi-solid state machining and integrating system, the structure is compact, equipment layout is reasonable, the operation is simple and convenient, a machining process is safe, process parameters are controlled precisely, the automation degree is high, semi-solid state product parts can be machined and produced continuously, effectively and excellently, and meanwhile, the machining and integrating system can also be used for the machining and forming of a common metal.

Owner:NANCHANG UNIV

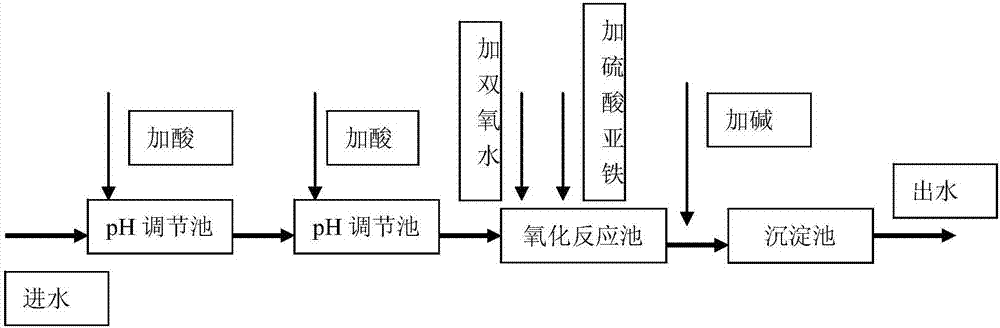

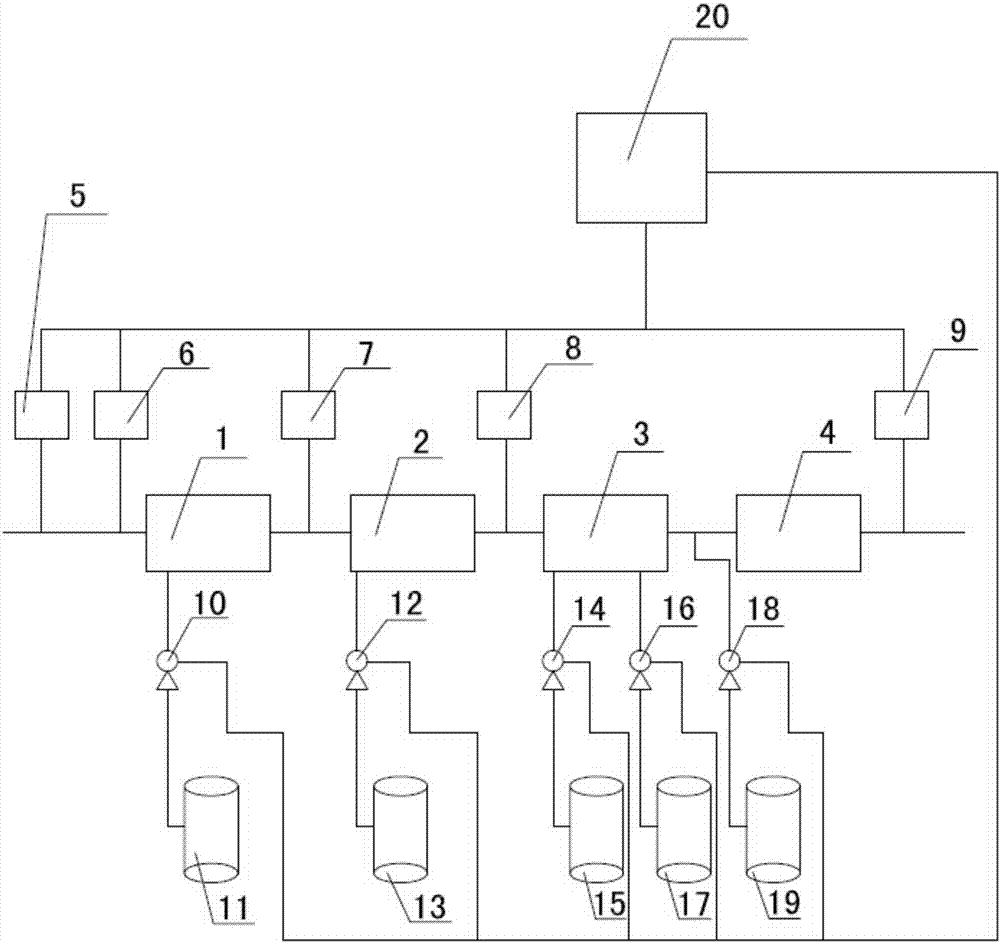

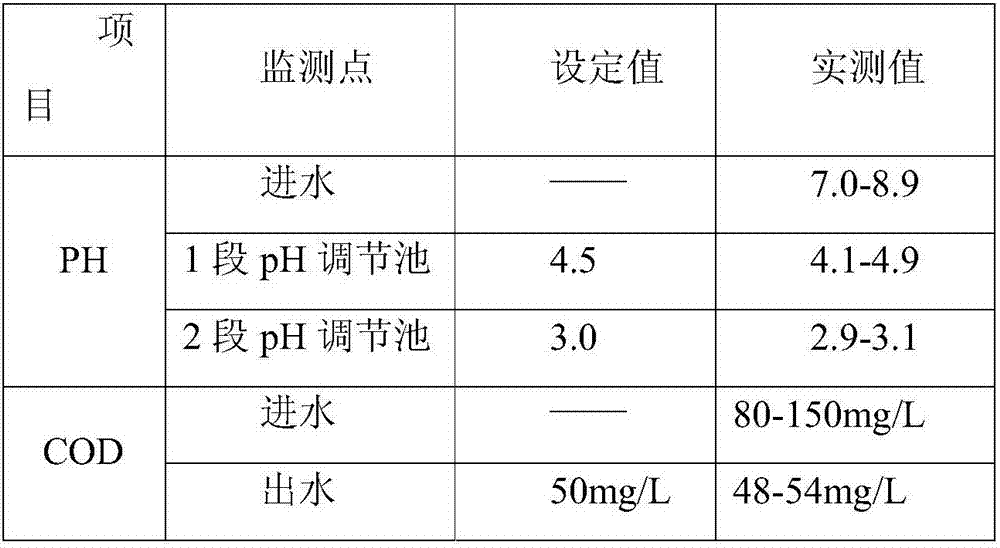

Fenton's reagent oxidation wastewater treatment method and device thereof

InactiveCN107473361AEasy to handleReduce processing costsWater treatment parameter controlWater treatment compoundsSulfatePh regulation

The invention belongs to the field of wastewater treatment technology and specifically relates to a Fenton's reagent oxidation wastewater treatment method and a device thereof. Wastewater to be treated enters a 1-stage pH regulating tank, and concentrated acid is extracted from a concentrated acid storage tank through an acid adding pump to carry out first-step pH regulation; an effluent from the 1-stage pH regulating tank enters a 2-stage pH regulating tank, and diluted acid is extracted from a diluted acid storage tank through an acid adding pump to carry out second-step pH regulation; an effluent from the 2-stage pH regulating tank enters an oxidation reaction tank, hydrogen peroxide and ferrous sulfate are added into an inlet of the oxidation reaction tank through a dosing pump, and a reaction is conducted after mechanical agitation or air agitation and mixing of the materials and wastewater; after pH regulation of an effluent from the oxidation reaction tank is achieved by addition of alkali, the effluent enters a sedimentation tank, and the effluent from the oxidation tank undergoes solid-liquid separation in the sedimentation tank and finally discharging is followed. Dosage of the oxidizer is controlled precisely so as to avoid less or excessive dosage of the drug. It is ensured that the treatment effect is stable, and treatment cost is effectively reduced. Degree of automation is high, and manual operation difficulty is reduced.

Owner:CHINA PETROLEUM & CHEM CORP

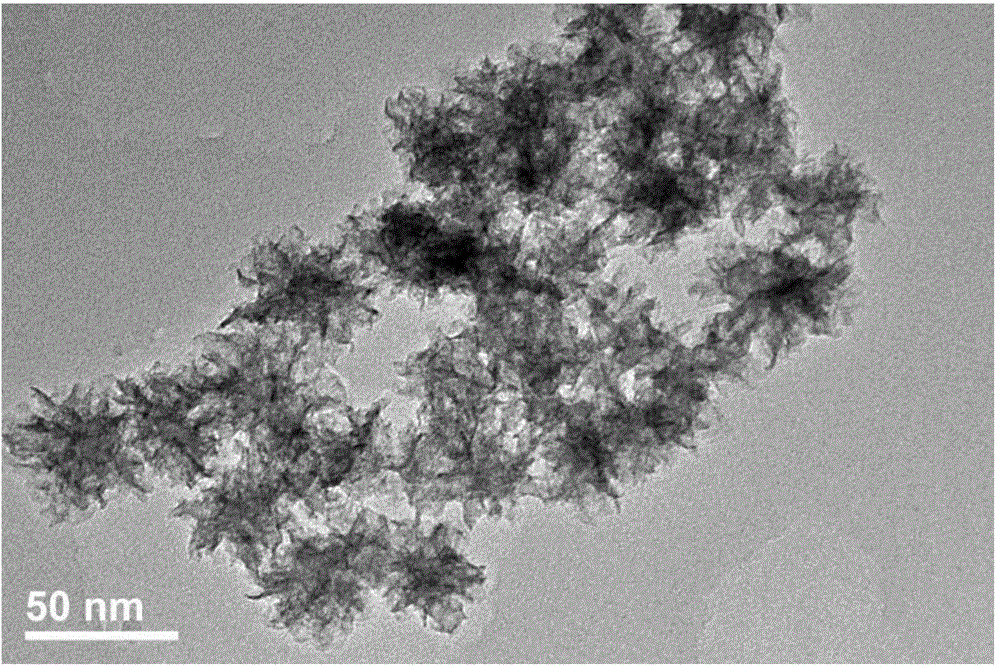

Environment-friendly preparation method of nano manganese oxide composite material

InactiveCN104671287ASimple processSimple and fast operationMaterial nanotechnologyManganese oxides/hydroxidesOrganic solventManganese oxide

The invention discloses an environment-friendly preparation method of a nano manganese oxide composite material. The environment-friendly preparation method comprises the following steps: (1) dissolving a certain amount of potassium permanganate into deionized water; (2) dispersing nano-conducting materials into a mixed solution of water and an organic solvent, and adding acid or alkali to regulate the pH value; (3) mixing the two solutions at a stirring or ultrasonic condition; and (4) drying to obtain manganese oxide composite powder after reaction for a period of time at a certain temperature. The prepared nano manganese oxide composite material has the characteristics that the particle size distribution is uniform, the shapes of products are regular and various, and the particle size is easily controlled. The preparation method has the beneficial effects that the preparation speed is high, the technological process is simple, the operation is convenient, the controllability is strong, the cost is low, the environmental pollution is avoided, and the application value is extremely high.

Owner:BEIHANG UNIV

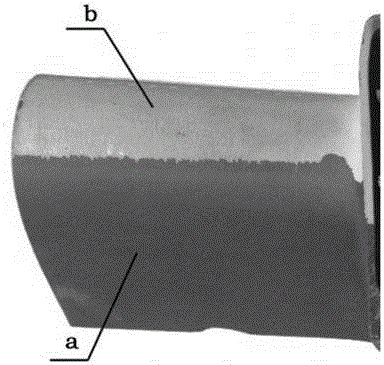

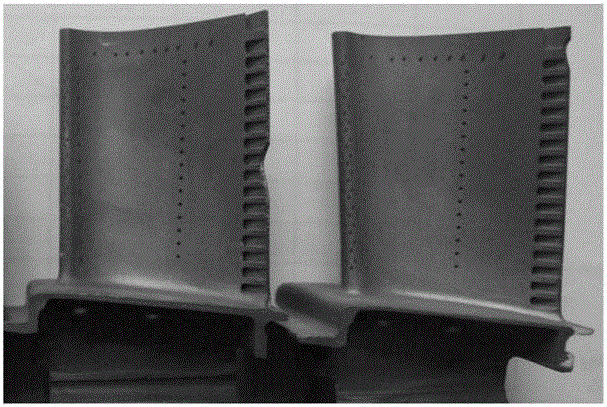

Method for removing ceramic layers of thermal barrier coating

InactiveCN106269648AEfficient removalGood removal effectCleaning using liquidsReciprocating motionSand blasting

The invention discloses a method for removing ceramic layers of a thermal barrier coating. The method includes the steps that (1) a turbine working blade is clamped on a tool fixture; (2) a nozzle is mounted in a spray gun; (3) under the condition of soft limiting control, the spray gun with the nozzle is slowly moved to the current surface, where one ceramic layer is to be removed, of the turbine working blade, and the target distance is kept; (4) an eddy current pulse water jet switch is turned on, and the nozzle is made to reciprocate line by line in the axial direction of the turbine working blade; (5) after the ceramic layer on the current surface of the turbine working blade is completely removed, the blade is rotated by 180 degrees through a rotating shaft on the tool fixture; and (6) the step (3) and the step (4) are conducted to remove the ceramic layer on the other face. When the method is used for removing the ceramic layers, the ceramic layers are continuously stripped off layer by layer, a metal bottom layer is not damaged, the metal bottom layer does not need to be coated supplementarily, the procedures are simple, and re-coating of the ceramic layers is facilitated; and compared with a traditional mechanical sand blasting method, process parameters are accurately controlled in the method, and product quality consistency is high.

Owner:AECC AVIATION POWER CO LTD

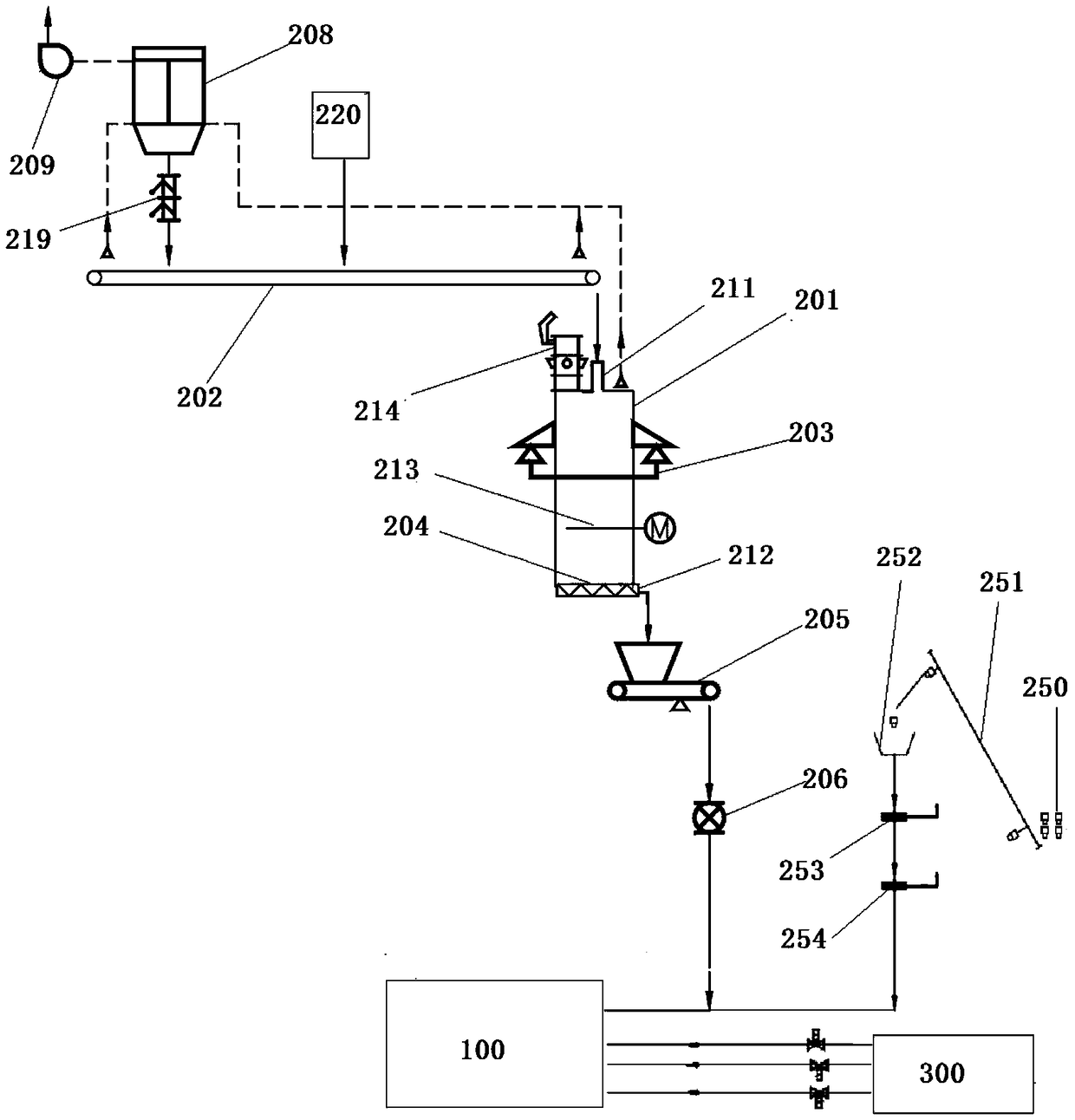

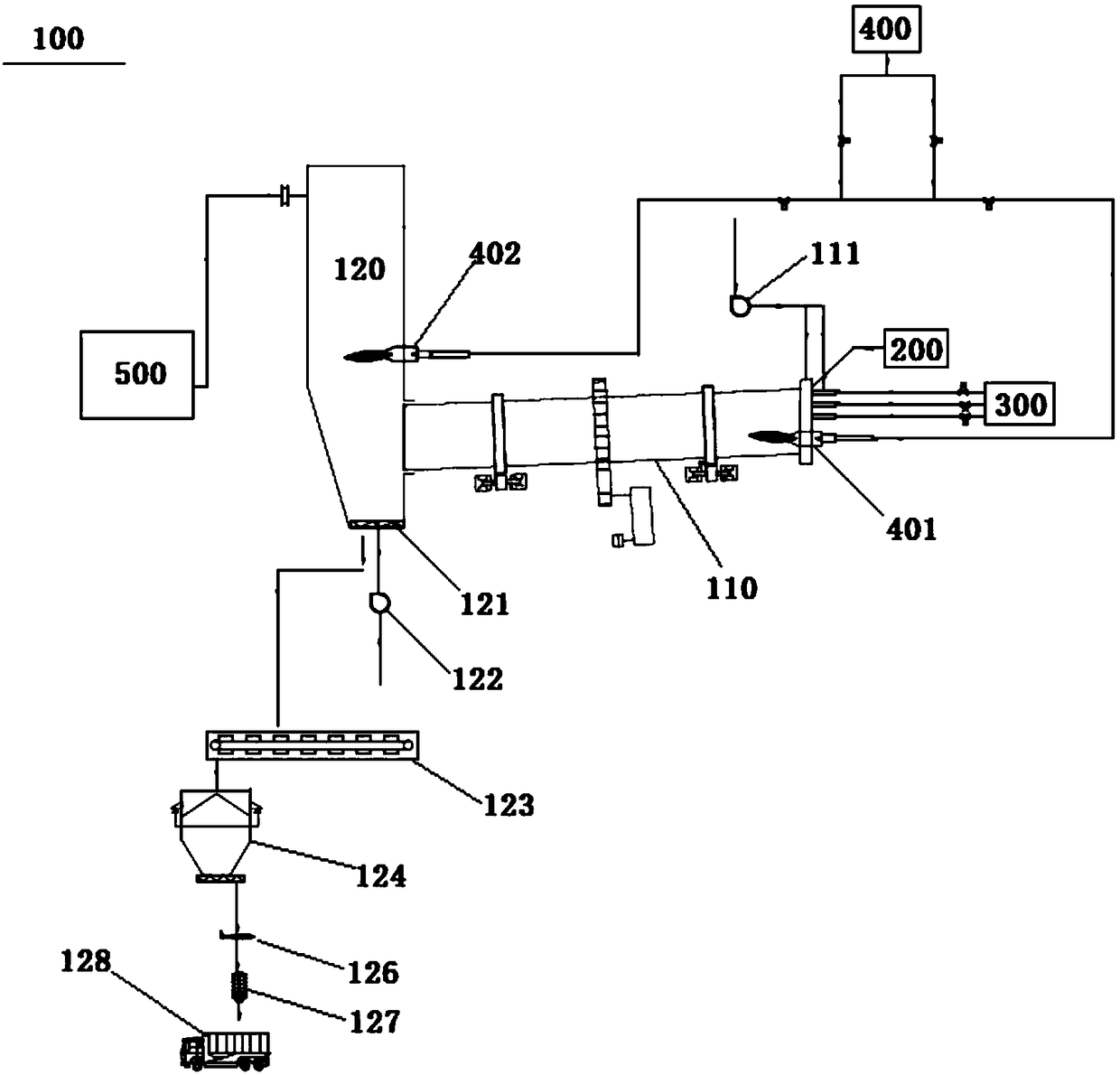

Hazardous waste incineration system and process

ActiveCN106247345ABurn completelyGuaranteed uptimeEmission preventionIndirect carbon-dioxide mitigationSlagChemical compatibility

The invention discloses a hazardous waste incineration system and process. The hazardous waste incineration system comprises feeding systems, an incineration device and a tail gas treatment system, wherein the feeding systems comprise a bulk material feeding system, a bagged material feeding system and a liquid material feeding system which convey bulk hazardous waste, bagged hazardous waste and liquid hazardous waste to the incineration device continuously and airtightly respectively. With adoption of the hazardous waste incineration system and process, through heat value and chemical compatibility of various types of hazardous waste, process parameters of the incineration device are controlled accurately, safe, stable and efficient operation of the incineration system is guaranteed, the hazardous waste is thoroughly incinerated, and tail gas and slag are treated efficiently without pollution.

Owner:北控安耐得环保科技发展常州有限公司

Antibacterial stainless steel and preparing method thereof

The invention particularly relates to antibacterial stainless steel and a preparing method thereof. According to the technical scheme of the antibacterial stainless steel and the preparing method thereof, stainless steel obtained after surface pretreatment is put into a dopamine buffer solution to be deposited for 0.1 h to 72 h under the condition with the temperature ranging from -5 DEG C to 40 DEG C; then the obtained stainless steel is put into a solution containing titanium ions to be deposited for 0.1 h to 6 h; and finally the obtained stainless steel is put into a solution containing silver ions to be deposited for 0.1 h to 6 h, and therefore the antibacterial stainless steel is obtained. The concentration of the dopamine buffer solution ranges from 0.01 mol / L to 1 mol / L, the concentration of the solution containing the titanium ions ranges from 0.001 mol / L to 1 mol / L, and the concentration of the solution containing the silver ions ranges from 0.001 mol / L to 1 mol / L. By means of the antibacterial stainless steel and the preparing method thereof, the technology is simple, environment friendliness is achieved, and the cost is low; the surface antibacterial nanometer film layer structure of the antibacterial stainless steel prepared through the method is well-defined and orderly, is firmly combined with a base material, is high in corrosion resistance and hardness and has good antibacterial performance both under the illumination condition and the non-illumination condition.

Owner:WUHAN UNIV OF SCI & TECH

Method for making automobile headlamp aspheric lens

InactiveCN1664642AGuaranteed accuracyLow precision, low surface smoothness, guaranteed production efficiencyGlass furnace apparatusGlass transportation apparatusAspheric lensOptical glass

This invention discloses one automobile before lamp non-sphere lens process method, which is characterized by the following: the lens is processed through heating, mode heating, shaping, cooling, taking out and annealing. The invention uses fine pressure optical glass method to process the lens to solve the traditional problem of low lens accuracy.

Owner:SHANDONG KANGYOU GLASS MATERIAL CO LTD

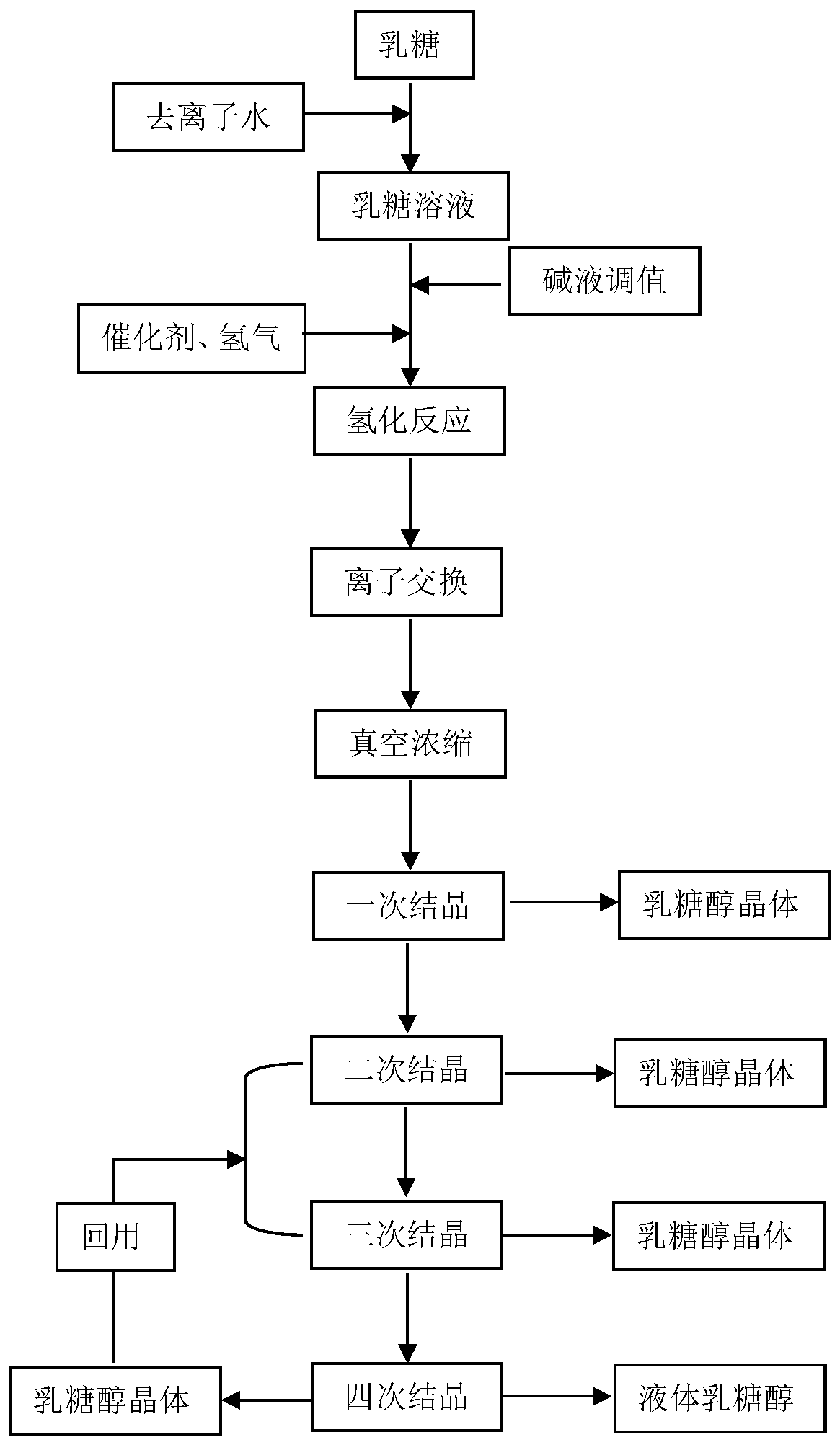

Production technology of lactitol

ActiveCN110818752AConvenient amountHigh activitySugar derivativesSugar derivatives preparationPtru catalystHydrogenation reaction

The present invention discloses a production technology of lactitol. Lactose is added into deionized water to prepare a lactose solution, pH is adjusted, a certain amount of a catalyst is added, a hydrogenation reaction is conducted under high temperature and high pressure to obtain a lactose hydrogenation solution, after the catalyst is removed, a lactitol solution is obtained, the lactitol solution is then purified, and concentration, crystallization and drying are conducted to obtain lactitol crystals. A primary crystallization yield of the lactitol relative to the lactose raw material reaches 55.0%-68.0% and a total yield of the lactitol relative to the lactose raw material reaches 92.2%-96.5%. At the same time, the technology is simplified in processes, liable for production and operation and also relatively low in production cost.

Owner:FUTASTE PHARM CO LTD

Method for continuously synthesizing sucralose

PendingCN113004345AImprove reaction efficiencyShort reaction timeSugar derivativesChemical industrySodium acetatePtru catalyst

The invention discloses a method for continuously synthesizing sucralose, which comprises the following step: in the presence of a catalyst, reacting dehydrated sucralose-6-acetate and anhydrous low-carbon alcohol serving as raw materials in a reactive distillation tower to generate sucralose, wherein the dehydrated sucralose-6-ester and the anhydrous low-carbon alcohol are used as raw materials, so that the problem that the catalyst is inactivated due to the fact that sodium acetate is generated by hydrolysis in the transesterification process caused by water in the raw materials is solved; and the ester exchange reaction and the methyl acetate separation process are combined in one device, and the product methyl acetate is timely moved out of the reaction zone from the tower top during the ester exchange reaction, so that the reaction can be promoted. The method makes full use of the advantages of the reactive distillation column, can effectively improve the reaction conversion rate and the equipment efficiency, reduces the energy consumption, reduces the production cost, and has a good application prospect.

Owner:FUZHOU UNIV

Low-temperature diffusion bonding method for adding quasi-crystal interlayers to aluminum-steel-aluminum

InactiveCN104191085APrecise control of process parametersLow costWelding/soldering/cutting articlesNon-electric welding apparatusParacrystallineAlloy

The invention discloses a low-temperature diffusion bonding method for adding quasi-crystal interlayers to aluminum-steel-aluminum. The method includes the main steps that quasi-crystal aluminum silicon copper middle transition alloy foil sheets are arranged between contact interfaces to be welded of aluminum plates and contact interfaces to be welded of a low-carbon steel plate, vacuum diffusion bonding is conducted, processing parameters are that the bonding temperature is controlled in the range of 420 degrees to 490 degrees, the heat preservation time under the bonding temperature ranges from 15 min to 25 min, the pressure ranges from 0.3 MPa to 0.9 MPa, and the vacuum degree is 1.33*10<-3> Pa-1.33*10<-2> Pa. By means of the method, low-temperature diffusion bonding of the aluminum and the low-carbon steel can be achieved, the diffusion interfaces of the formed aluminum-steel-aluminum composite structure is firm in combination, reliable in bonding quality and high in production efficiency. The low-temperature diffusion bonding method for adding the quasi-crystal interlayers to aluminum-steel-aluminum has the advantages of being precise in processing parameter control, low in cost and the like, and the bonding temperature can be reduced.

Owner:SHANDONG UNIV

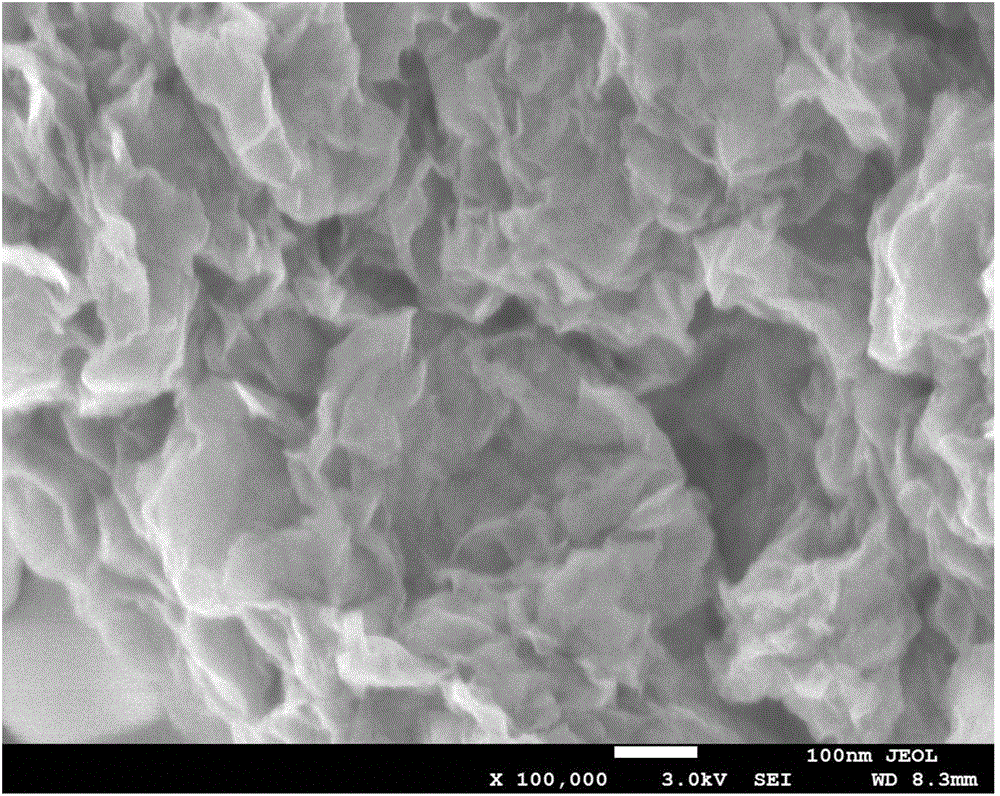

Preparation method for mixed powder of graphene and titanium alloy

The invention belongs to the field of powder titanium alloy materials and relates to a preparation method for mixed powder of nanometer materials and titanium alloy, in particular to the preparation method for mixed powder of graphene and titanium alloy. Firstly, spherical titanium alloy powder is prepared by the method of argon atomization or plasma rotation electrode atomization; then, accurately weighed graphene nanosheets are added to absolute ethyl alcohol, dispersion treatment is conducted by a high-speed dispersion stirrer and an ultrasound cell pulverizer, and a graphene solution is prepared; finally, the spherical titanium alloy powder and the graphene solution are stirred and mixed in a quantitative burdening tin of a temperature-controlled mechanical stirring device, mixed powder slurry of the graphene and the titanium alloy is prepared, and the mixed powder of the graphene and the titanium alloy is obtained after drying treatment and vacuum degassing. According to the preparation method for the mixed powder of the graphene and the titanium alloy, the dispersion performance of the graphene nanosheets in the titanium alloy powder is improved, the operation method is easy, the technological parameters are accurately controlled, the preparation method is suitable for batch preparation of the mixed powder of the graphene and the titanium alloy, and the application prospect is wide.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

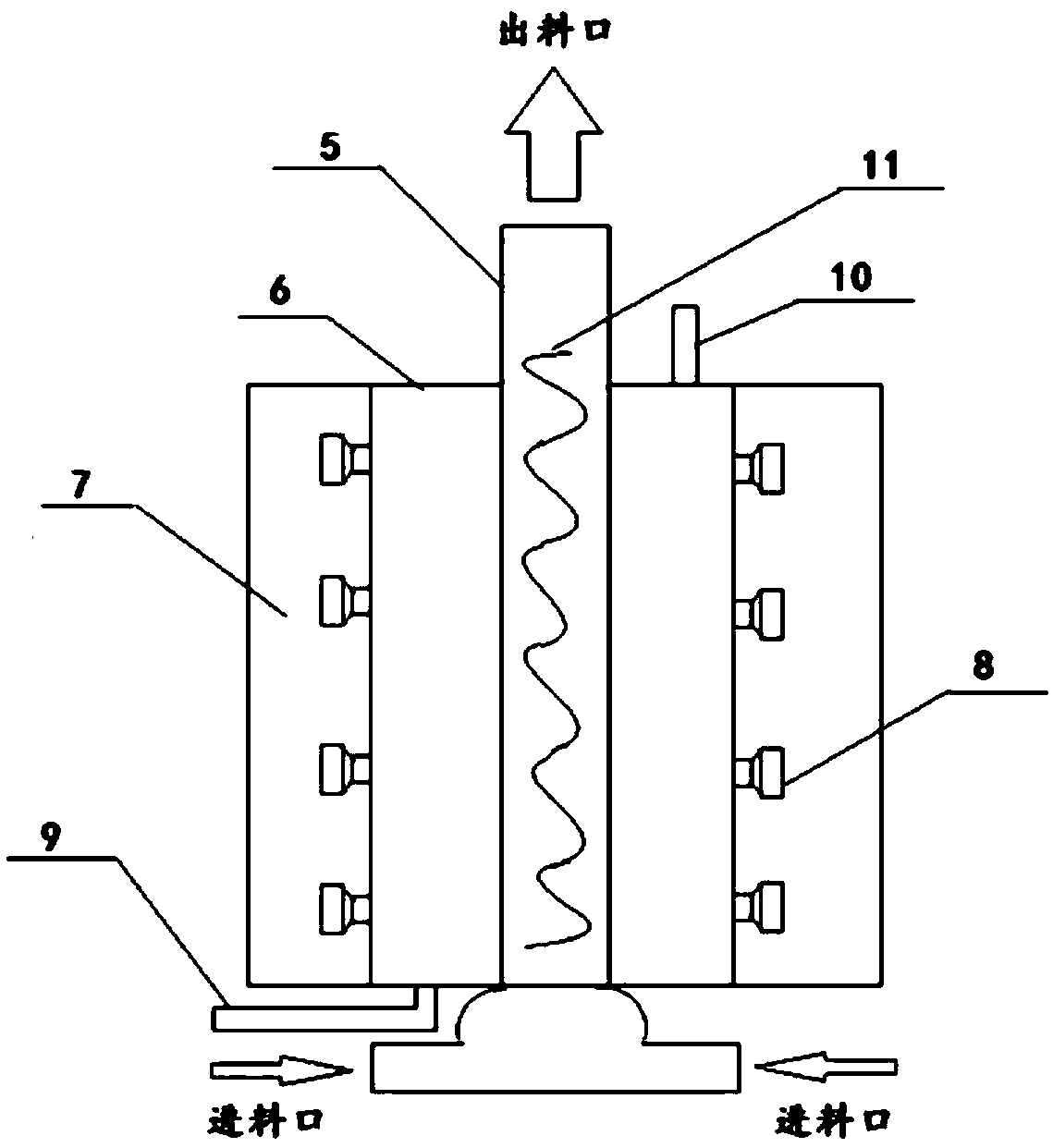

Continuous pressure sintering device and process for high-speed heavy-load brake pad

InactiveCN103673612AIncrease productivityReduce the number of layersFurnace typesHigh energyMetallic materials

The invention belongs to a technology for preparing metal powder and a composite material of a metal material, and provides a continuous pressure sintering device and process for a high-speed heavy-load brake pad. The device comprises an upper computer, a half-open furnace body, a scaffold car and a horizontal type long-barrel-tunnel-shaped high-temperature alloy furnace tube, wherein the upper computer is used for controlling, the half-open furnace body is used for achieving the heat insulation and preservation functions, and the section of the high-temperature alloy furnace tube is rectangular. By the adoption of the device, multiple kinds of metal powder, alloy powder and graphite powder or oxide powder or carbide powder can be prepressed into parison and then pressure sintering is conducted on the parison, and meanwhile the parison and steel backing substrates are welded, and then various high-speed heavy-load brake materials or components can be made. The technology and the device are suitable for automatic, continuous and massive production of the brake materials or components of high-speed walking machines such as airplanes, railway high-speed trains and superior quality cars. Compared with a bell jar type furnace, the device is high in automation level, low in energy consumption, high in product quality, uniform and stable in performance and high in production efficiency, and the production environment is greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

Hazardous waste incineration process

ActiveCN108800153ABurn completelyGuaranteed uptimeEmission preventionIndirect carbon-dioxide mitigationCombustion chamberSlag

The invention discloses a hazardous waste incineration process. The hazardous waste incineration process comprises the following steps: (1) proportioning a bulk material, a bagged material and a liquid substance according to a preset heat value and chemistry compatibility, and separately feeding the bulk material, the bagged material and the liquid substance in a continuous and airtight mode through a bulk material feeding system, a bagged material feeding system and a liquid substance feeding system; (2) incinerating the fixed carbon part of the hazardous waste in a rotary kiln, wherein volatile combustible gas and fine carbon particles generated in a pyrolysis process into a secondary combustion room to be burned out at a high temperature; and (3) feeding hot slag generated in the rotarykiln and the secondary combustion room into an air cooled slag extractor for heat exchange, and directly conveying the cooled slag to a slag cabin. By adopting the hazardous waste incineration process disclosed by the invention, process parameters in an incineration device are controlled accurately by means of heat value and chemistry compatibility of various hazardous wastes, so that an incineration system is safe, stable and efficient to operate.

Owner:BEIJING BEIKONG ENVIRONMENTAL PROTECTION ENG TECH CO LTD

Preparation method of magnesium-zinc-tricalcium phosphate composite material by powder hot pressed sintering

The invention discloses a preparation method of a magnesium-zinc-tricalcium phosphate composite material by powder hot pressed sintering, which comprises the following steps: evenly mixing 55-98 wt% of magnesium powder, 1-15 wt% of zinc powder and 1-30 wt% of tricalcium phosphate at room temperature; putting the mixed powder in a die, and carrying out press forming at room temperature; putting the formed composite material blank in a die, and carrying out pressed sintering in a nitrogen protective atmosphere; after the thermal insulation of the sintering is completed, relieving the pressure, and naturally cooling to room temperature; stripping, taking out the sintered composite material, and carrying out heat treatment at 200-400 DEG C for 1-8 hours in a nitrogen protective atmosphere; and finally, forging the composite material blank at 300-500 DEG C under the pressure of 50-100MPa. The invention has the characteristics of short production technique process and high technical implementation feasibility; and the prepared magnesium-zinc-tricalcium phosphate composite material has the characteristics of accurate component control and excellent comprehensive properties.

Owner:CENT SOUTH UNIV

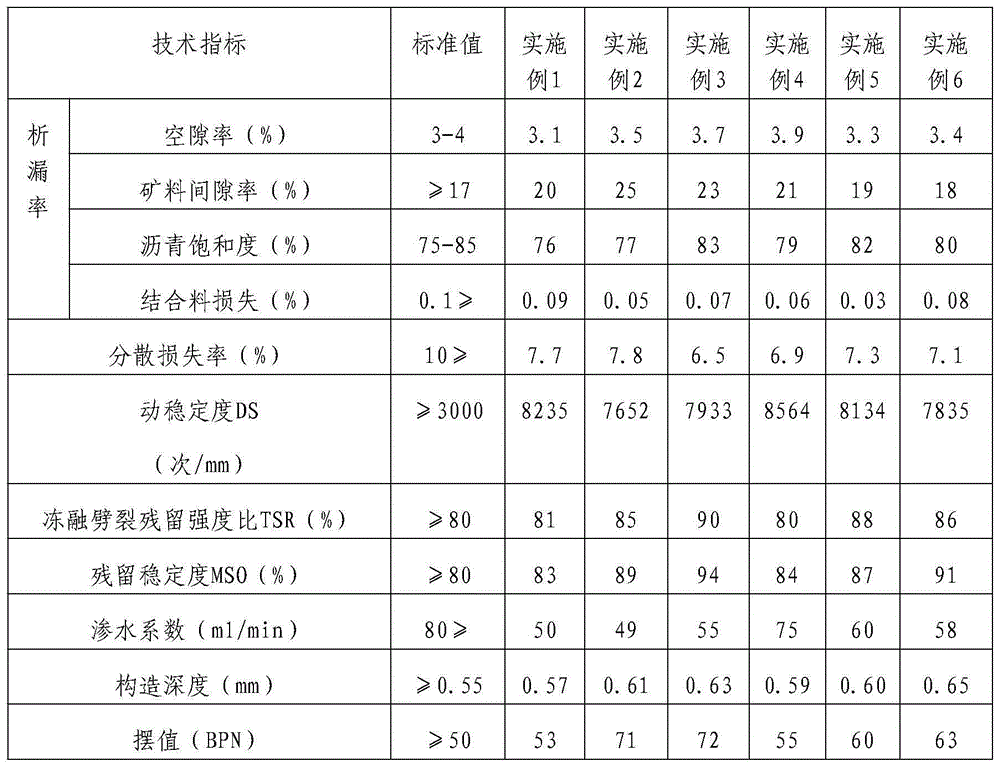

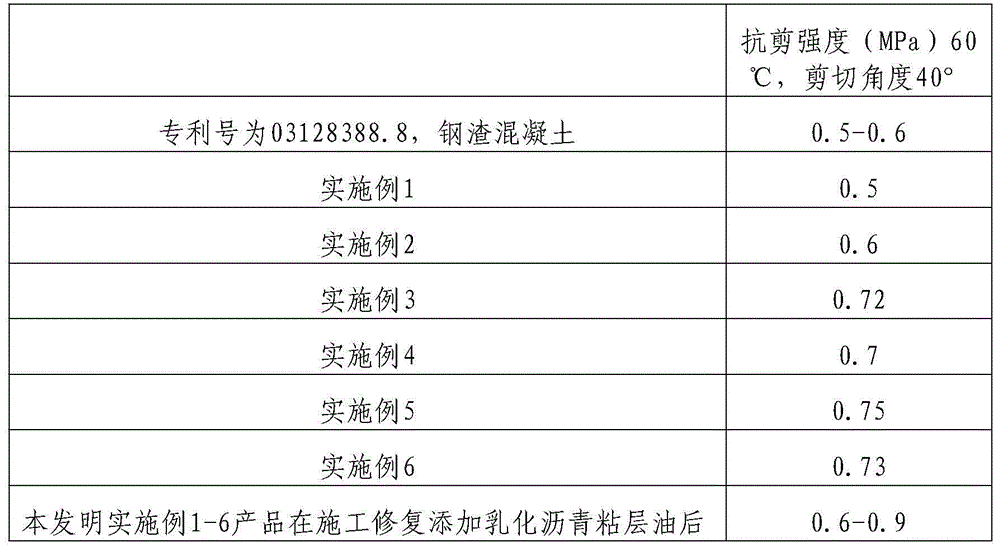

SMA mixture, and preparation method and application thereof

The invention relates to the field of rapid restoration materials for disease asphalt pavements and application of the rapid restoration materials, and especially relates to an SMA mixture, and a preparation method and application thereof. The SMA mixture is composed of, in parts by weight, 7-8 parts of aggregate, 2-4 parts of mineral powder, 0.35-0.45 part of fiber and 2-3 parts of additives. The additives comprise resin, modified asphalt, heavy traffic paving asphalt, an asphalt regenerant and a milling material. The preparation method of the SMA mixture comprises: preparing a primary finished product of the additive, preparing a semi-finished product of the additive, adding mineral powder, adding other raw materials and stirring and performing detection, so as to obtain the SMA mixture. By combining a construction method for the asphalt disease pavement and accurately controlling the technological parameters of steps, rapid appropriate fusion among joints can be realized, the step of adding modified asphalt for filling joints in the conventional technology is avoided, the cost is reduced and the construction period is shortened.

Owner:GUANGSHA CONSTR GROUP

Pesticide emulsion water preparation method, and emulsion water prepared based on method, and applications thereof

InactiveCN110651784ASmall particle sizeNarrow distributionBiocidePlant growth regulatorsEmulsionInsect pest

The invention relates to a pesticide emulsion water preparation method, and emulsion water prepared based on the method, and applications thereof. The preparation method comprises: (1) preparing a dispersed oil phase and a continuous water phase; and (2) treating the dispersed oil phase and the continuous water phase in a micro-reaction system to obtain oil-in-water emulsion water. The invention further relates to applications of the pesticide emulsion water in prevention and treatment of diseases, insect pests and weeds in crop protection. According to the invention, the pesticide emulsion water with good stability is prepared by selecting the micro-reaction technology.

Owner:JIANGSU ROTAM CHEM

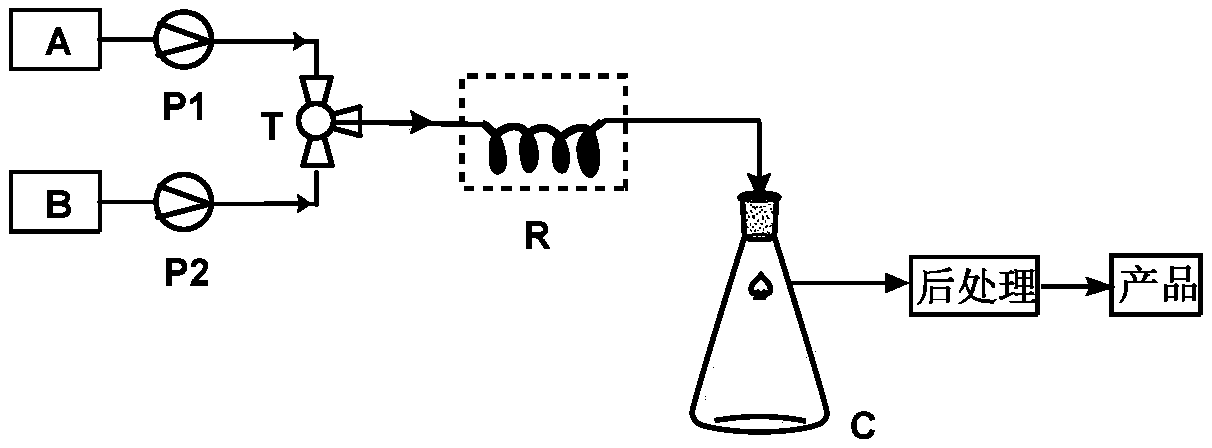

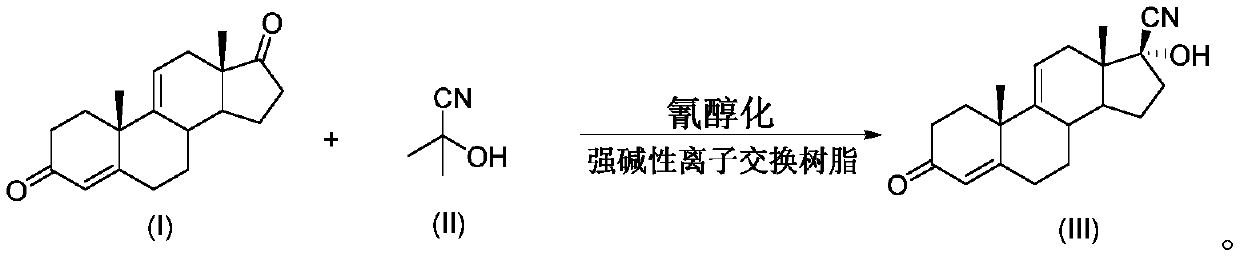

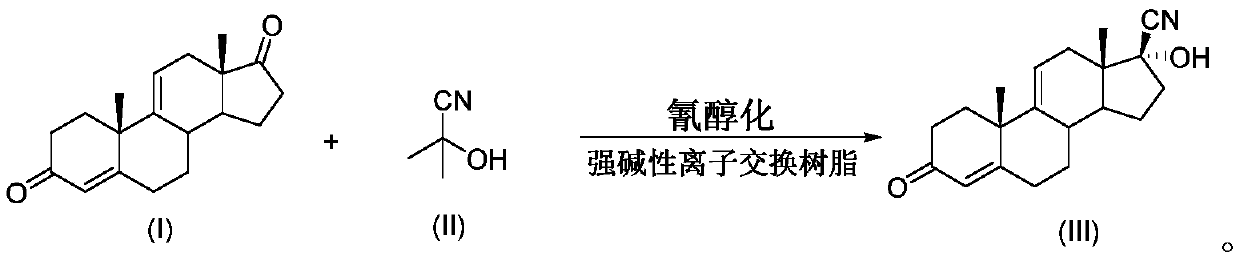

Method for preparing 17beta-cyano-17alpha-hydroxy-9-dehydroandrostenedione

InactiveCN111320665ASmall amount of online responseReduce backmixingSteroidsChemical/physical processesOrganic solventIon exchange

The invention discloses a method for preparing 17 beta-cyano-17 alpha-hydroxy-9-dehydroandrostenedione. The method comprises the following steps: (1) dispersing 9-dehydroandrostenedione (I) and acetone cyanohydrin (II) into an organic solvent; (2) carrying out a cyanohydrination reaction on the obtained mixed raw material liquid in a tubular reactor filled with strongly basic ion exchange resin, and (3) carrying out post-treatment on the material liquid after the cyanohydrination reaction to obtain 17beta-cyano-17alpha-hydroxy-9-dehydroandrostenedione (III), the reaction formula of which is shown in the specification.

Owner:台州仙琚药业有限公司

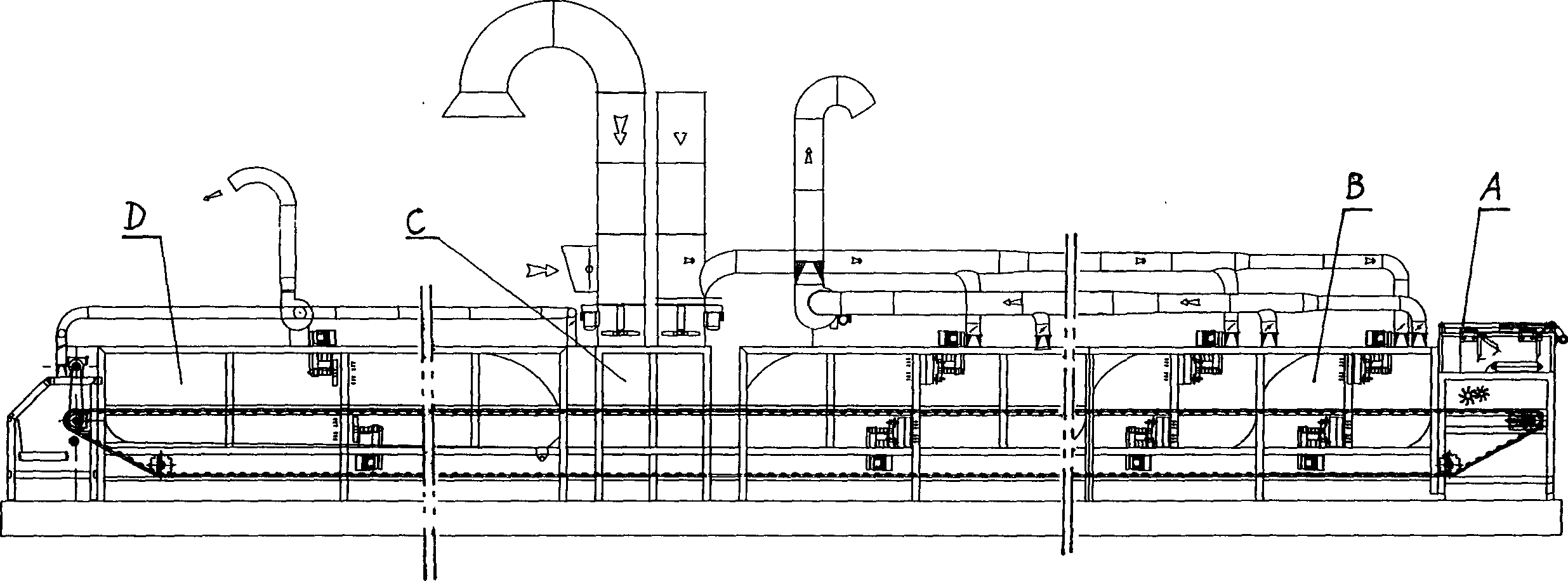

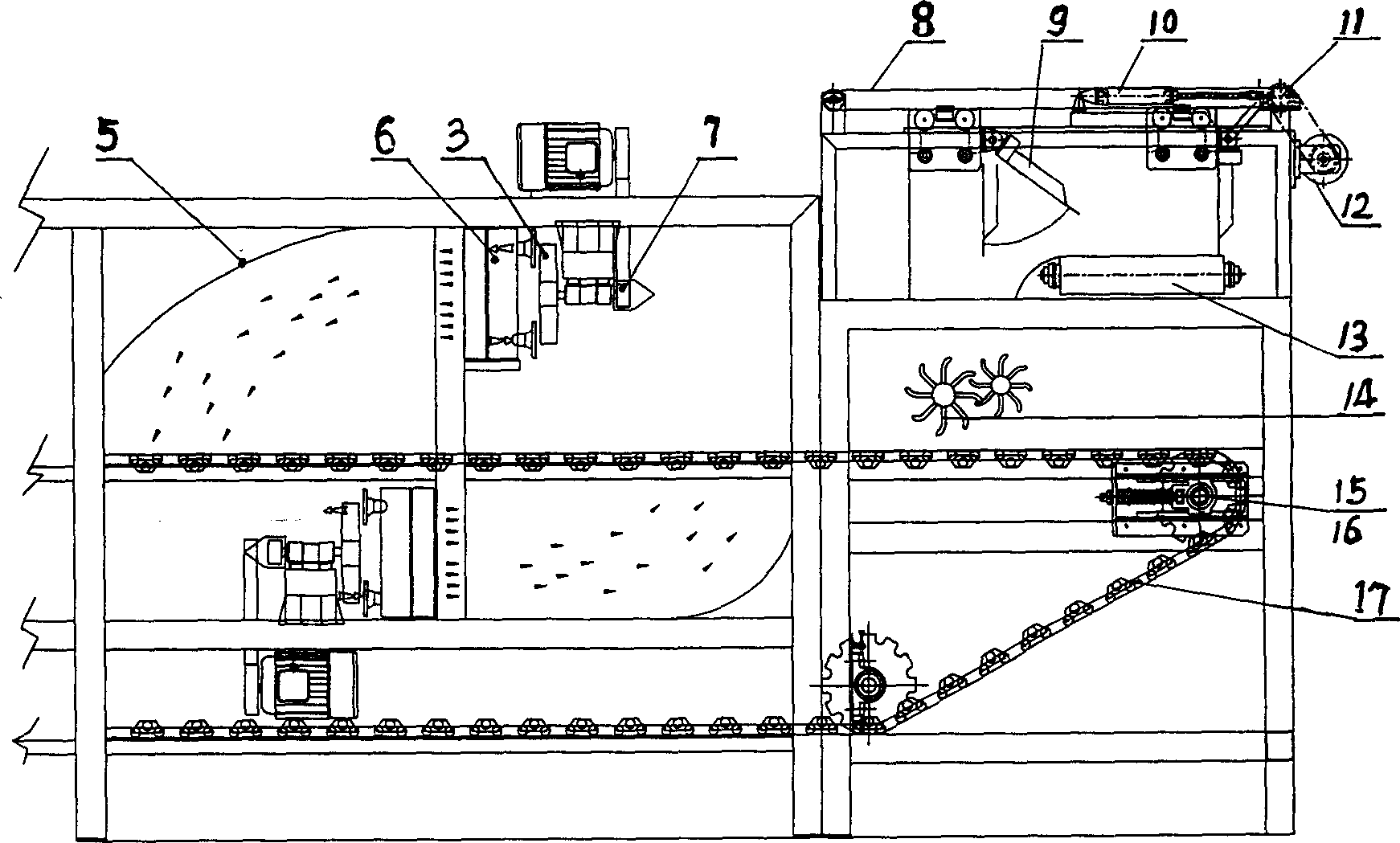

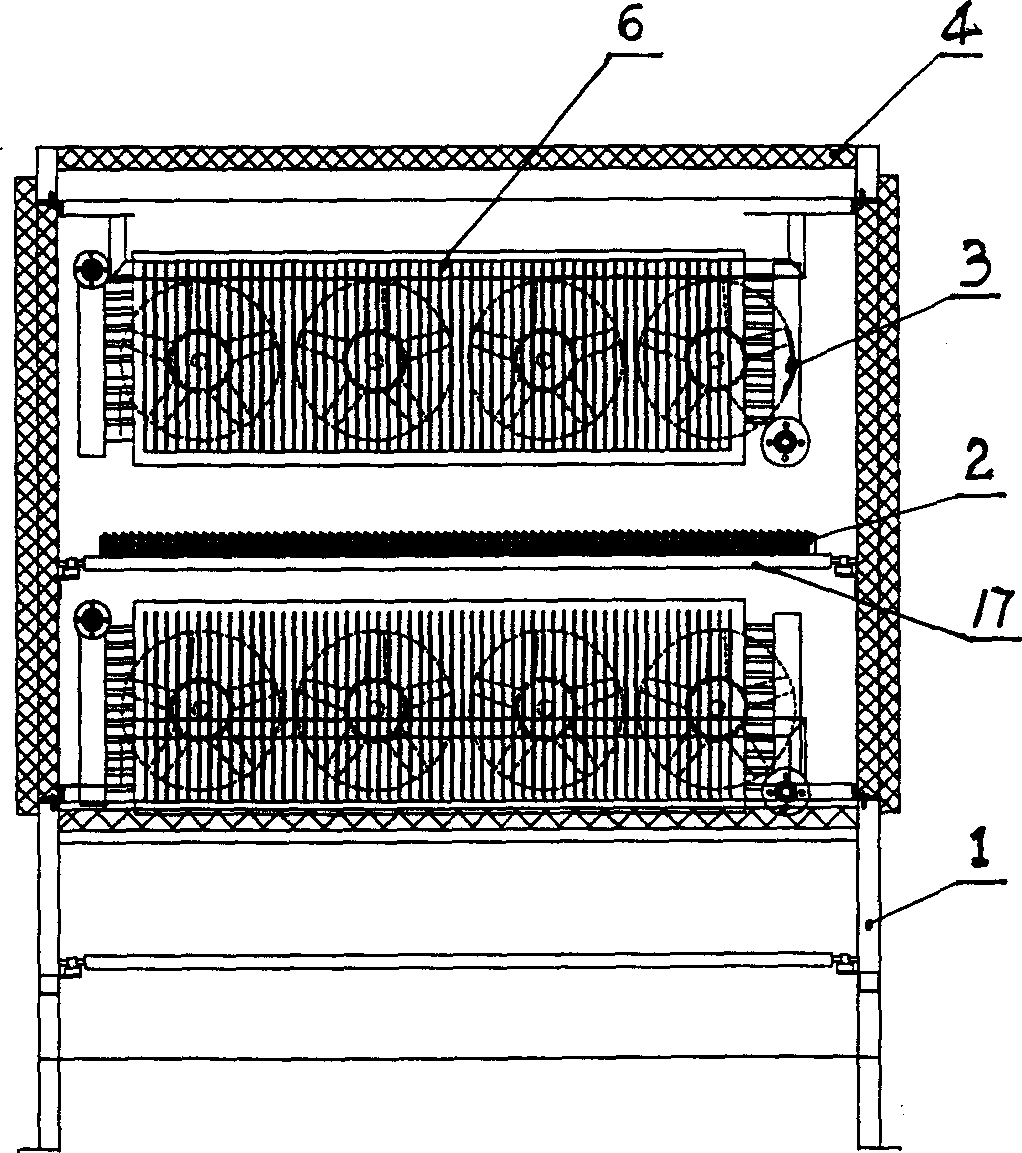

Symmetrical type white rib smoke dryer

InactiveCN1514197APrecise control of process parametersReduce consumptionDrying machinesAir heaterSmoke

A dryer is set with fan and air heater or air humidifier symmetrically at top and bottom position of net belt to make hot air or wet air directly form circulation at top and bottom of material layer in box based on existing machine so no need of drying side chamber and humidifying side chamber.

Owner:徐加贵

Kettle-pressure extrusion integrated micro-foaming extrusion forming device and kettle-pressure extrusion integrated micro-foaming extrusion forming method

InactiveCN108312413AImprove performanceRealize continuous extrusionFlat articlesMotor driveGas cylinder

The invention discloses a kettle-pressure extrusion integrated micro-foaming extrusion forming device and a kettle-pressure extrusion integrated micro-foaming extrusion forming method. The kettle-pressure extrusion integrated micro-foaming extrusion forming device mainly consists of a material feeding system, a gas feeding system and an extrusion system; the material feeding system is connected with a material feeding device of a machine barrel of the extrusion system; the gas feeding system provides the material feeding system with supercritical gas; and the material feeding system mainly consists of a storage hopper, a motor, a motor driving shaft, a gear, a key, a transmission piece, a pressure piece, a sealing barrel, a permeating kettle, a sealing gasket, a spring, a roller, a gas cylinder, a gas cylinder pull rod, a sealing plate, a limiting block and a pressure rod. A granular raw material is permeated, so that the penetrating time is shortened substantially, continuous extrusion of micro-foaming products is achieved, and the production efficiency is improved; the granular raw material is subjected to supercritical gas permeating through the permeating kettle, so that technological parameters are controlled accurately, the foaming quality is higher, and the property of the product is better; and the gas after being permeated can be recycled in a working process, so thata use ratio of the gas is increased compared with that in the traditional kettle-pressure foaming method.

Owner:BEIJING UNIV OF CHEM TECH

Colored stainless steel based on ion implantation and preparation method thereof

InactiveCN102021525BThe process steps are simpleProcess environment is cleanVacuum evaporation coatingSputtering coatingRoom temperatureHardness

The invention relates to a colored stainless steel based on ion implantation and a preparation method thereof. The technical scheme is as follows: placing a stainless steel to be colored in a vacuum chamber of an ion implantation apparatus, vacuumizing to 0.1-1*10<-5>Pa, and implanting ions on the surface of the stainless steel to obtain the colored stainless steel, wherein the accelerating voltage for ion implantation is 10-100kV, and the ion implantation amount is 1*10<17>-1*10<19> ions / cm<2>; or placing a stainless steel to be colored in a vacuum chamber of an ion implantation apparatus, vacuumizing to 0.1-1*10<-5>Pa, and implanting ions on the surface of the stainless steel, wherein the accelerating voltage for ion implantation is 10-100kV, and the ion implantation amount is 5*10<15>-5*10<19> ions / cm<2>; and taking out, carrying out heat treatment, and cooling to room temperature in the furnace to obtain the colored stainless steel. The invention has the advantages of simple process and clean environment, and the obtained colored stainless steel has the characteristics of multiple color varieties, high reproducibility, uniform color, beautiful appearance, high durability and no separation. Compared with the stainless steel prior to preparation, the surface hardness and the corrosion resistance are obviously improved.

Owner:WUHAN UNIV OF SCI & TECH

Double-skin milk and making process thereof

InactiveCN105454431AStrong tasteThe entrance is tenderMilk preparationAdditive ingredientOxalic acid

The invention discloses double-skin milk. The double-skin milk is made of, by weight, 10-15 parts of milk, 60-70 parts of cream, 6-10 parts of egg white, 2-5 parts of xylitol, 1-3 parts of stevia rebaudianum, 1-3 parts of sweet oxalic acid and 1-3 parts of aspartame. Milk and cream are adopted as raw materials, egg white, xylitol, stevia rebaudianum, sweet oxalic acid and aspartame are added, and the ingredients are mixed to form the double-skin milk. The made double-skin milk is fragrant in smell, smooth in taste, fine and smooth in taste, agreeably sweet, rich in level and particularly suitable for being eaten by people suffering from diabetes.

Owner:HUBEI SHENDAN HEALTHY FOOD

Method for removing medium and low-molecular-weight polysiloxane in silicone rubber

InactiveCN109467703APrecise control of process parametersLow Molecular Content ControlledPolymer scienceSealant

The invention belongs to the field of high polymer materials and relates to a method for removing medium and low-molecular-weight polysiloxane in silicone rubber. The method uses devices such as a vacuum oven, a film evaporator, a vacuum distiller and a short range distiller to remove the low-molecular-weight polysiloxane in the silicone rubber, and the required silicone rubber with the low-molecular-weight polysiloxane removed is obtained by controlling the temperature, the vacuum degree, the velocity of the silicone rubber, and the removing times. The used method for removing the low-molecular-weight polysiloxane is simple, the contents of the medium and low-molecular-weight polysiloxane in the obtained silicone rubber are controlled, and the method can be used in various fields such assilicone sealants, auto lamps, photoelectric components, and medical apparatuses and instruments.

Owner:南京天双辰新材料有限公司

A kind of preparation method of graphene and titanium alloy mixed powder

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

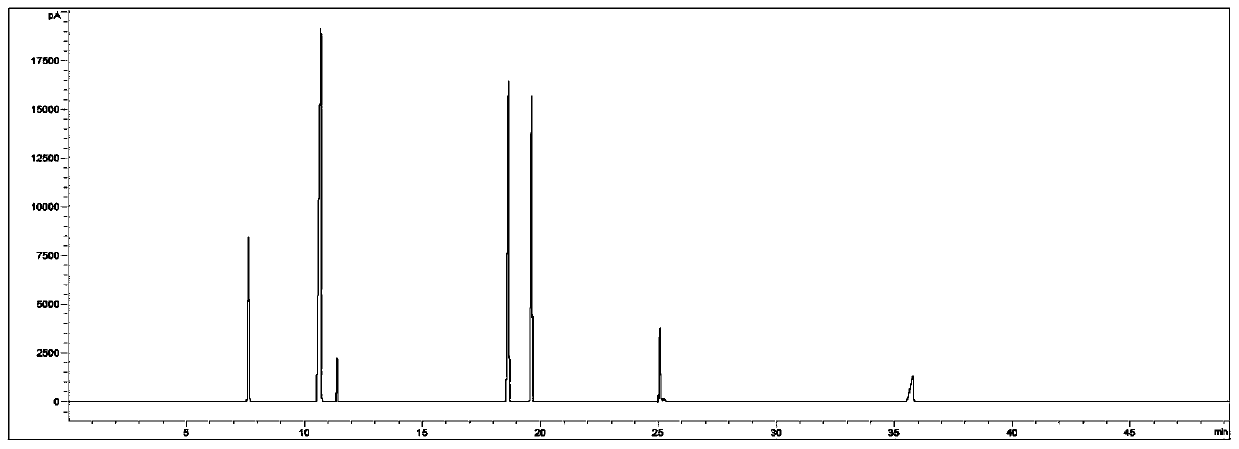

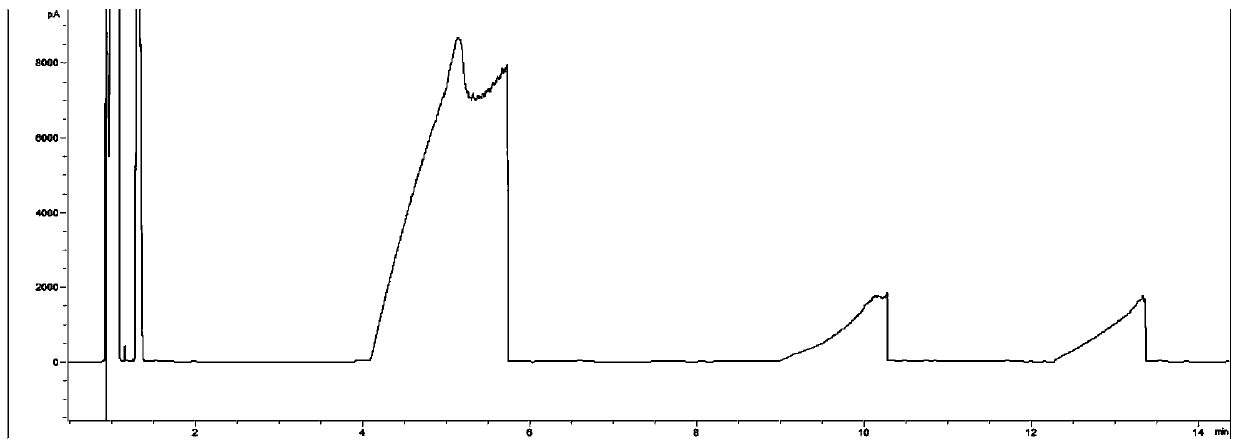

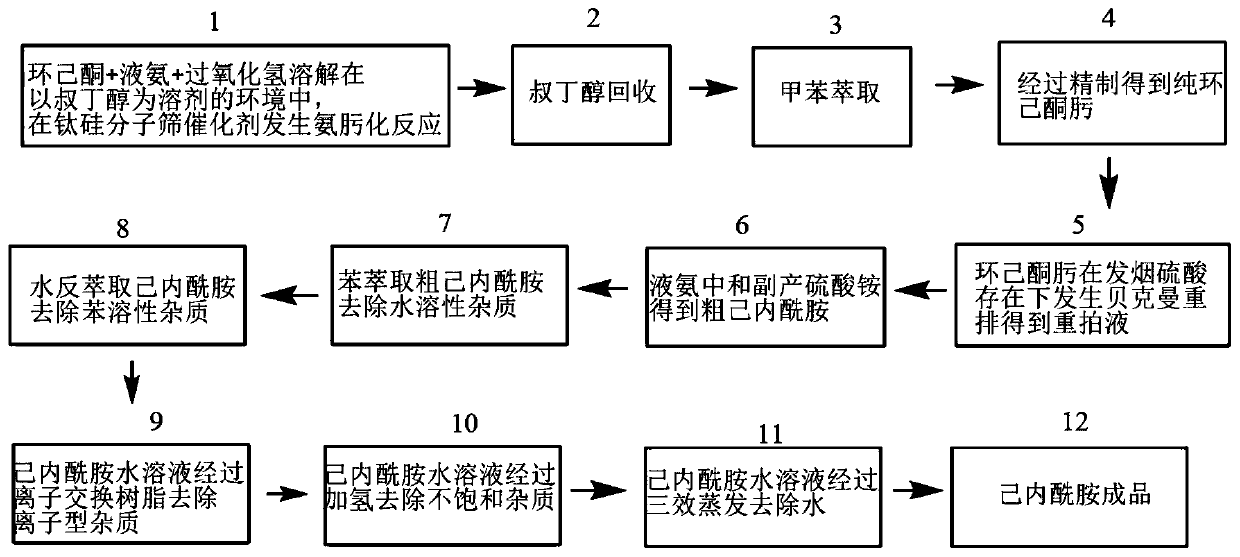

Gas chromatography detection method in caprolactam production process

ActiveCN111521723APrecise control of process parametersEasy to separateComponent separationBulk chemical productionGas liquid chromatographicPolyethylene glycol

The invention relates to a gas chromatography detection method in a caprolactam production process. The method uses gas chromatography to detect an intermediate product at a quality control point in caprolactam production, and the gas chromatography uses a strongly polar chromatographic column stationary liquid selected from at least one of bonded polyethylene glycol and cross-linked polyethyleneglycol. According to the gas chromatography detection method in the caprolactam production process, the separation effect is high, and the impurity detection capacity is good. The impurity analysis capability of each control point in the caprolactam production process is improved, and caprolactam production enterprises can be better guided to carry out lean production control.

Owner:沧州旭阳化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com