Anti-fatigue manufacturing method of spiral bevel gear

A manufacturing method and technology of bevel gears, which are applied in the field of gear manufacturing, can solve problems such as heavy pollution, elimination, and high energy consumption, and achieve the effects of reduced production costs, reduced energy consumption, and improved fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Below in conjunction with accompanying drawing, the 9-step operation specific embodiment of the curved bevel gear anti-fatigue manufacturing method of the present invention is described in detail:

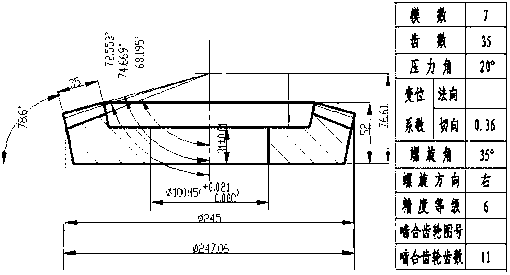

[0084] 1. Attached figure 1 The part drawing of the given curved bevel gear is prepared, the material is 42Cr2Mo, the forging ratio should be ≥ 3, and the one-time forming die forging process is adopted.

[0085] 2. After the blank is removed from the mold, it enters the isothermal normalizing process with waste heat from forging, and its heat treatment process curve is according to the attached figure 2 Process curve implementation in Zone I. The isothermal temperature for 42Cr2Mo steel is 680 ±5 ℃, the hardness value is 180-190HB, and the average grain size is grade 6.

[0086] 3. After the rough turning of the gear blank, it is transferred to the CNC lathe for finishing turning, and all parts meet the process requirements.

[0087] 4. The tooth blank is semi-finish-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com