Method for removing ceramic layers of thermal barrier coating

A technology of thermal barrier coating and ceramic layer, applied in the direction of liquid cleaning method, chemical instrument and method, cleaning method and utensils, etc., can solve the problem of metal bottom layer thinning, etc., and achieve easy recoating and reasonable angle design , Improve the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

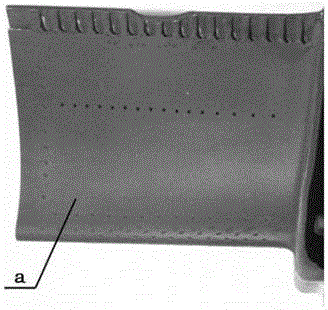

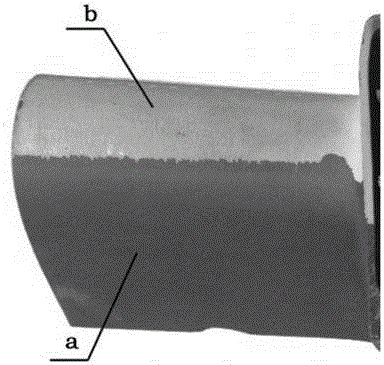

[0042] 1) First, tape the image 3 Protect the area 1 in order to verify the thinning of the metal bottom layer before and after the removal of the ceramic layer, and clamp the blade in the fixture;

[0043] 2) Install a nozzle with a diameter of 0.3mm in the spray gun;

[0044] 3) In the case of soft limit control, slowly move the spray gun with the nozzle to the corresponding blade surface, and set the target distance to 30mm;

[0045] 4) Set the pulse water pressure of the vortex pulse water jet to remove the ceramic layer to 40MPa, the nozzle moving speed to 0.02m / s, and the incident angle to 45°, turn on the vortex pulse water jet switch, and make the nozzle along the figure 1 The direction of the white arrow in figure 1 Change the line in the direction of the black arrow in to achieve the effect of continuous and layer-by-layer peeling of the ceramic layer.

[0046] 5) After the leaf basin of the blade is removed, the 180° rotation of the blade is realized through the...

Embodiment approach 2

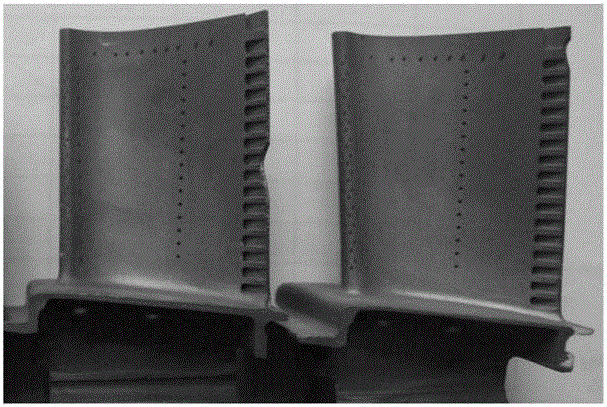

[0054] 1) First, clamp the two blades in the fixture;

[0055] 2) Install a nozzle with a diameter of 0.5mm in the spray gun;

[0056] 3) In the case of soft limit control, slowly move the spray gun with the nozzle to the corresponding blade surface, and set the target distance to 50mm;

[0057] 4) Set the pulse water pressure of the vortex pulse water jet to remove the ceramic layer to 60MPa, the nozzle moving speed to 0.05m / s, and the incident angle to 60°, turn on the vortex pulse water jet switch, and make the nozzle along the figure 1 reciprocate in the direction of the white arrow in ; at the same time, along the figure 1 Change the line in the direction of the black arrow in to achieve the effect of continuous and layer-by-layer peeling of the ceramic layer.

[0058] 5) After one side of the blade is removed, the 180° rotation of the blade is realized through the rotating shaft on the fixture;

[0059] 6) Utilize steps 3) and 4) to complete the removal of the ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com