Patents

Literature

30results about How to "Easy to recoat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental-friendly diatom ooze inner wall latex paint and preparation method thereof

InactiveCN106752430AGood balance and washableWell-balanced breathabilityEmulsion paintsEmulsionDefoaming Agents

The invention discloses an environmental-friendly diatom ooze inner wall latex paint which is prepared from the following components by weight percent: 12-18% of benzene acrylic emulsion, 10-15% of kieselguhr, 3-6% of titanium dioxide, 0.1-0.5% of a dispersing agent, 0.1-0.5% of a wetting agent, 0.5-1% of a thickening agent, 25-38% of packing, 0.2-0.4% of a defoaming agent, 1-1.5% of ethanol, 0.5-1% of a surfactant, 0.3-0.6% of an anti-molding agent and 25-40% of water, wherein the total percentage of the component is 100%. The invention further discloses a preparation method of the latex paint. Due to the addition of the kieselguhr and controlling the addition amounts of additives of the latex paint, the scrubbing resistance and the air permeability of the latex paint can be in optimal balance, the source of VOC (Volatile Organic Compounds) in the latex paint is reduced, and a prepared coating is safe and environmentally friendly, stable in property, soft and uniform in coating quality and good in adhesive property with a base material.

Owner:ZHONGSHAN MOORE CHEM IND CO LTD

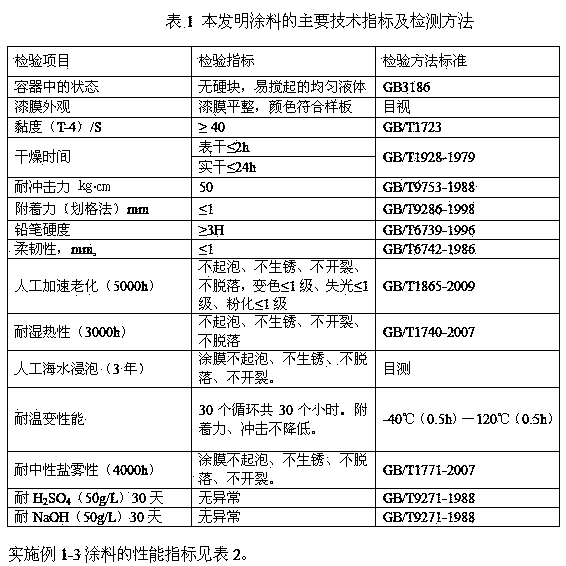

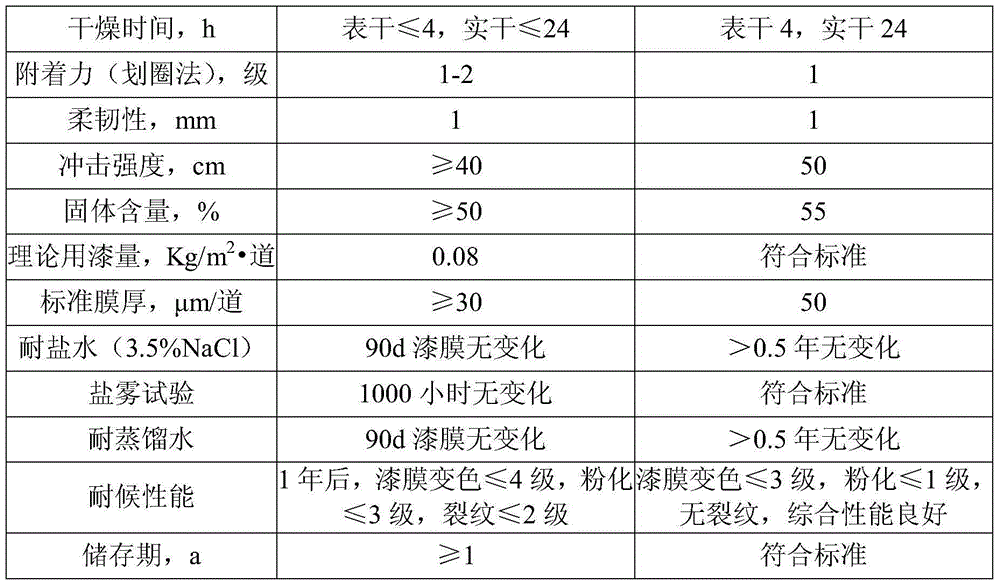

Waterborne epoxy resin cabin coating and preparation method thereof

InactiveCN110982380AStrong adhesionImprove impact resistanceAnti-corrosive paintsEpoxy resin coatingsPolymer scienceFirming agent

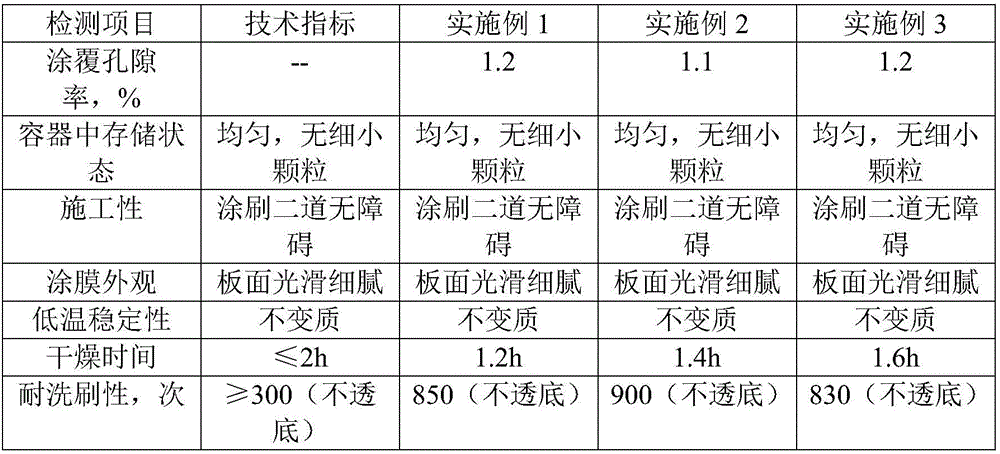

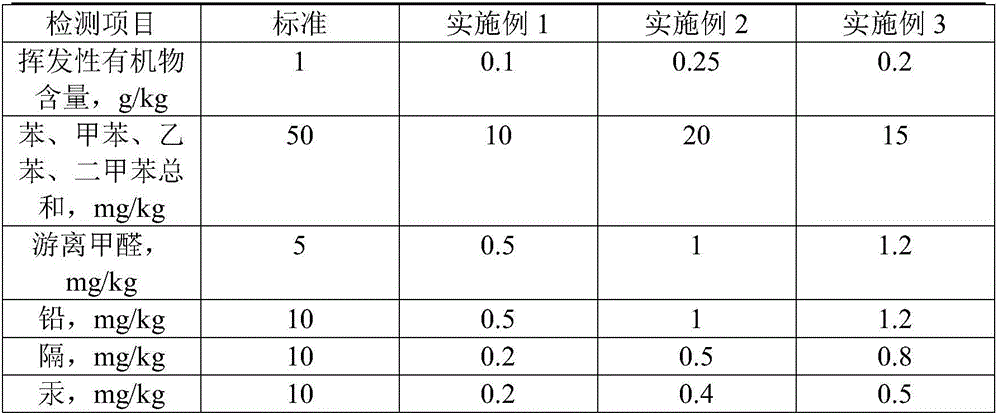

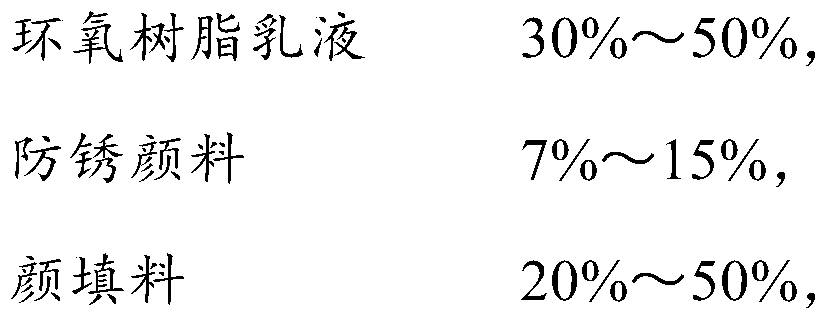

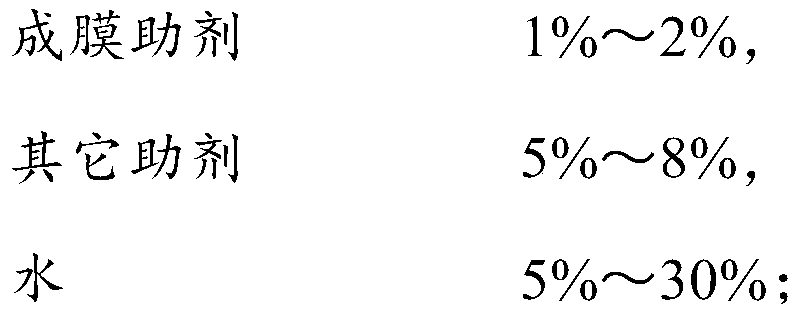

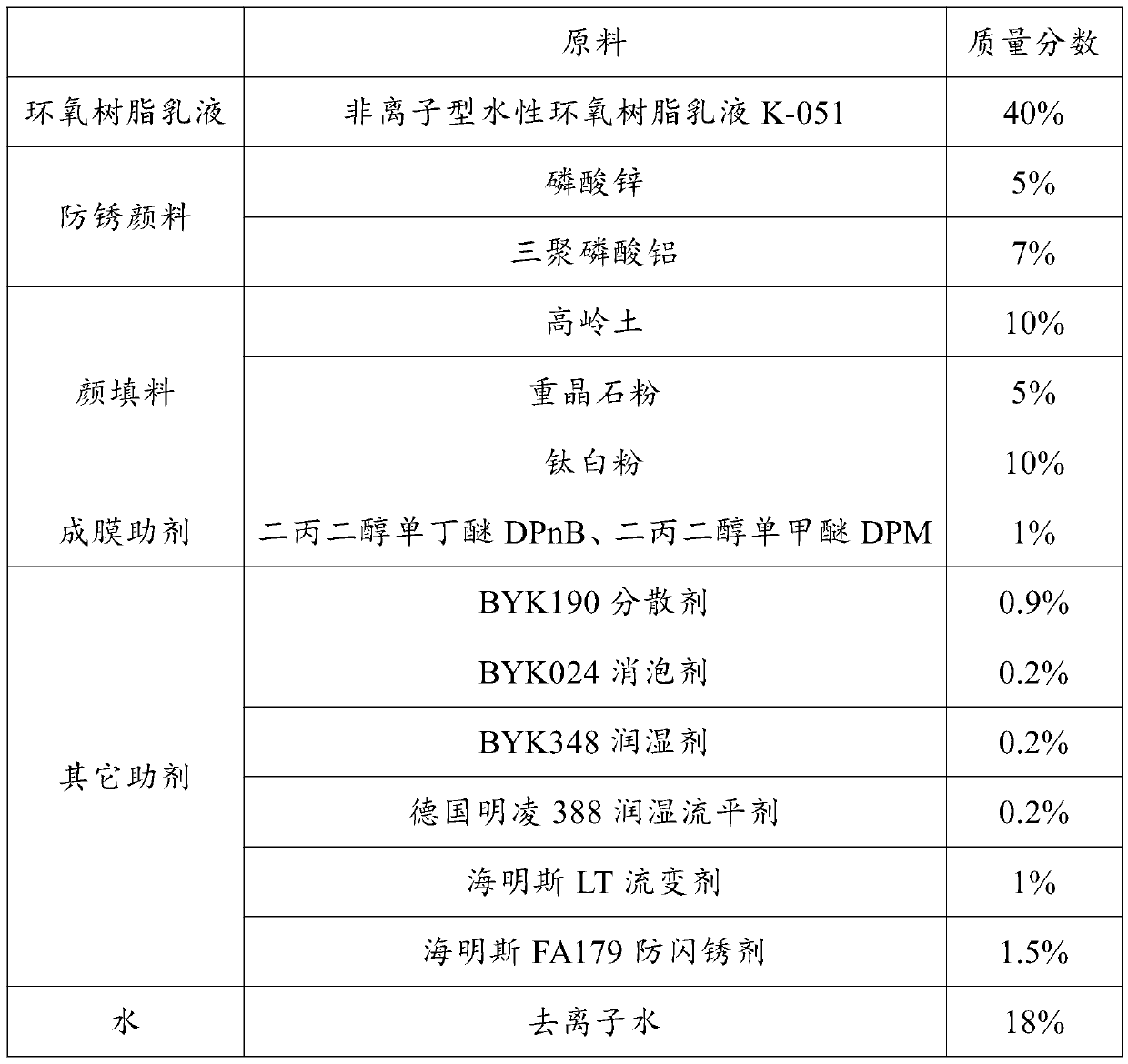

The invention provides a waterborne epoxy resin cabin coating. The coating comprises a component A and a component B in a weight ratio of (8-5): 1. The component A comprises the following components in percentage by mass: 30%-50% of an epoxy resin emulsion, 7%-15% of an antirust pigment, 20%-50% of a pigment filler, 1%-2% of a coalescing agent, 5%-8% of other auxiliaries and 5%-30% of water. The component B is a water-based epoxy amine curing agent with a solid content of 45-55% and with a solvent being water. According to the waterborne epoxy resin cabin coating, the VOC content of a cured paint film meets the environmental protection standard that the VOC content is smaller than or equal to 80 g / L, the adhesive force between the paint film and a substrate is larger than or equal to 5 MPa, the water contact angle of the paint film reaches 100 degrees or above and is kept stable, and recoating is easy; and the waterborne epoxy resin cabin coating has excellent salt spray resistance andcorrosion resistance.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

Synthetic latex diatom inner wall emulsion paint and preparation method thereof

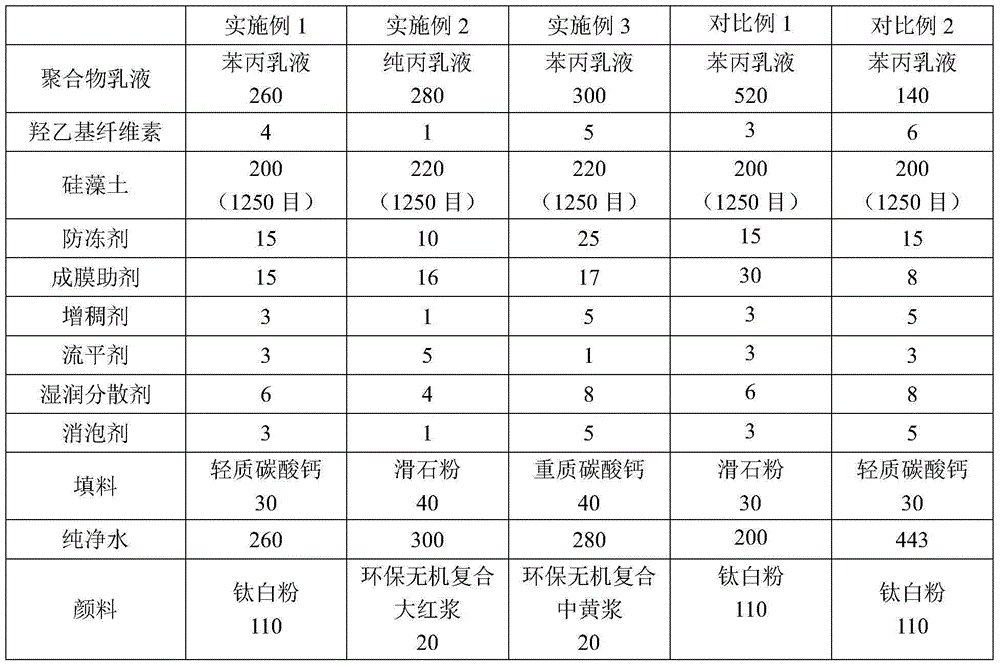

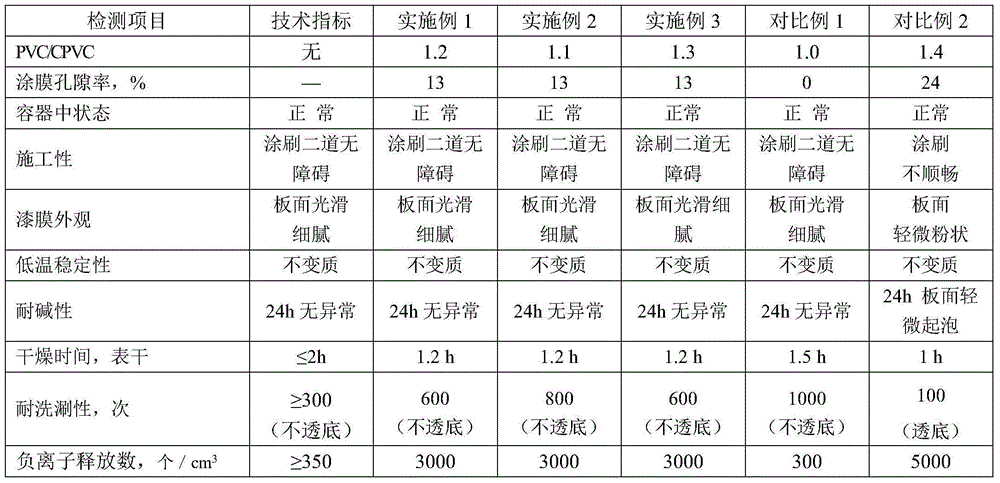

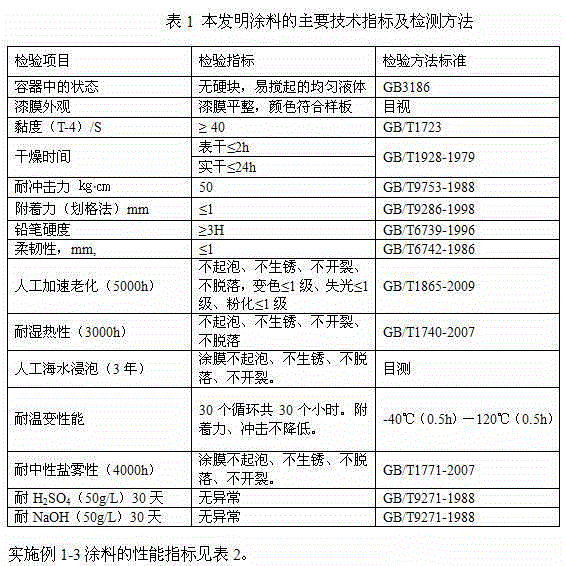

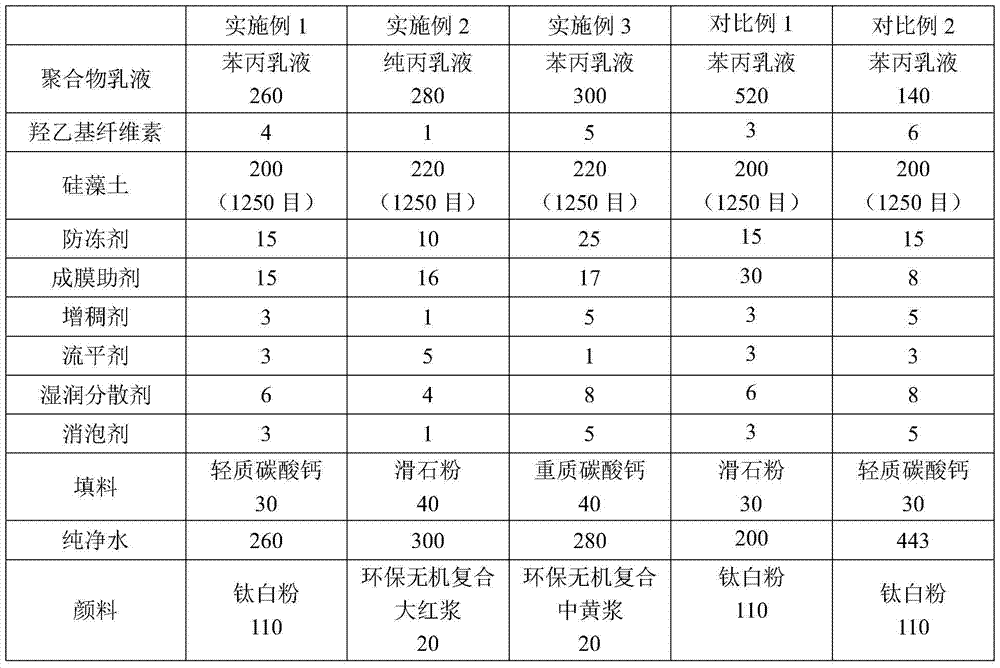

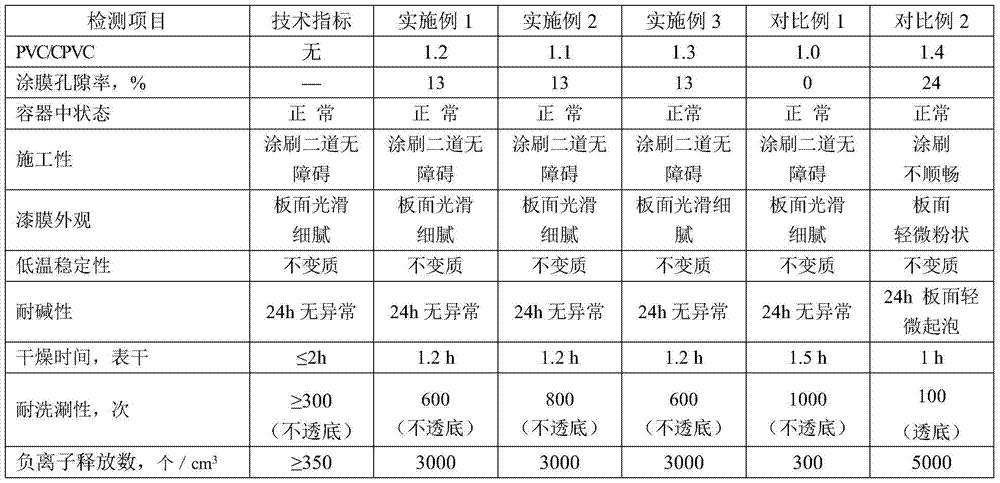

ActiveCN105176220AEasy constructionReduce construction costsAnti-corrosive paintsEmulsion paintsAnti freezingEmulsion

The invention discloses synthetic latex diatom inner wall emulsion paint and a preparation method thereof. The inner wall emulsion paint is prepared from, by weight, 260-300 parts of polymer emulsion, 1-5 parts of hydroxyethyl cellulose, 200-220 parts of diatomite, 10-25 parts of anti-freezing agents, 15-17 parts of film-forming auxiliaries, 1-5 parts of thickeners, 1-5 parts of flatting agents, 4-8 parts of wetting dispersants, 1-5 parts of defoaming agents, 60-120 parts of filler and 300-315 parts of water. The PVC / CPVC of the emulsion paint is 1.1-1.3. The PVC is the pigment size concentration of the emulsion paint, and the CPVC is the critical pigment volume concentration of the emulsion paint. The inner wall emulsion paint has water resistance, washability and air permeability at the same time, and the diatomite can effectively release anions.

Owner:ZHANG ZHOU SAN PAINTS +1

Low-temperature quick-drying water road sign coating and preparation method thereof

InactiveCN101125997AEasy to useGood osmotic wettabilityTraffic signalsEmulsion paintsHigh rateTitanium oxide

The invention relates to a low temperature resistant and quick drying waterborne road mark paint and a preparation method thereof. The component weight proportion of the white paint of the invention is of 30-45 percent of organosilicon-acrylic acid polymer emulsion, 0.5-2.5 percent of dispersion agent, 5-10 percent of titanium oxide, 40-55 percent of filler, 2-6 percent of film-forming additive, 0.2-1 percent of anti-foam agent, 0.2-1 percent of pH regulator and the rest proportion of water. The yellow paint of the invention is based on the white paint components which are added with yellow pigment of 2.0-5.0 percent and the preparation method thereof comprises the steps that: (1) dispersion agent is added to the organosilicon-acrylic acid polymer emulsion; (2) filling and titanium oxide are added to mixed solution of the emulsion and the dispersion agent and then are sheared or grinded at high rate; (3) the anti-foam agent and next the film-forming additive are added, pH value is adjusted and water is added to adjust balance. The paint is applicable to low temperature and dries quickly, and has the advantages of environmental friendliness, energy conservation, safety and reliability, being easy to be recoated, simple preparation technique and short preparation time, thereby being applicable to industrial production.

Owner:姜鲁锡 +2

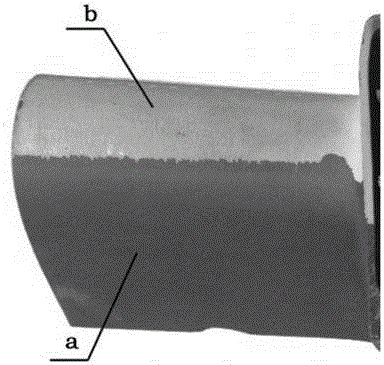

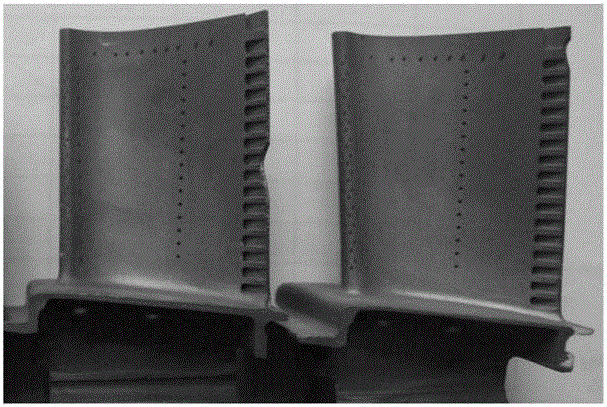

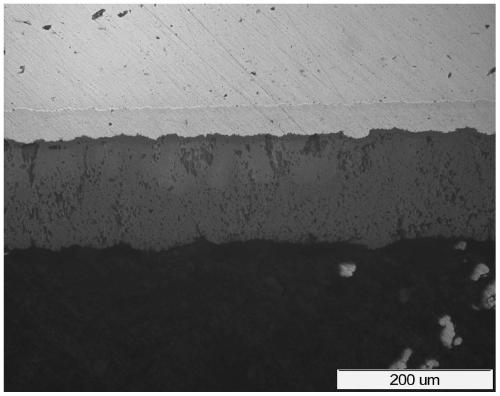

Method for removing ceramic layers of thermal barrier coating

InactiveCN106269648AEfficient removalGood removal effectCleaning using liquidsReciprocating motionSand blasting

The invention discloses a method for removing ceramic layers of a thermal barrier coating. The method includes the steps that (1) a turbine working blade is clamped on a tool fixture; (2) a nozzle is mounted in a spray gun; (3) under the condition of soft limiting control, the spray gun with the nozzle is slowly moved to the current surface, where one ceramic layer is to be removed, of the turbine working blade, and the target distance is kept; (4) an eddy current pulse water jet switch is turned on, and the nozzle is made to reciprocate line by line in the axial direction of the turbine working blade; (5) after the ceramic layer on the current surface of the turbine working blade is completely removed, the blade is rotated by 180 degrees through a rotating shaft on the tool fixture; and (6) the step (3) and the step (4) are conducted to remove the ceramic layer on the other face. When the method is used for removing the ceramic layers, the ceramic layers are continuously stripped off layer by layer, a metal bottom layer is not damaged, the metal bottom layer does not need to be coated supplementarily, the procedures are simple, and re-coating of the ceramic layers is facilitated; and compared with a traditional mechanical sand blasting method, process parameters are accurately controlled in the method, and product quality consistency is high.

Owner:AECC AVIATION POWER CO LTD

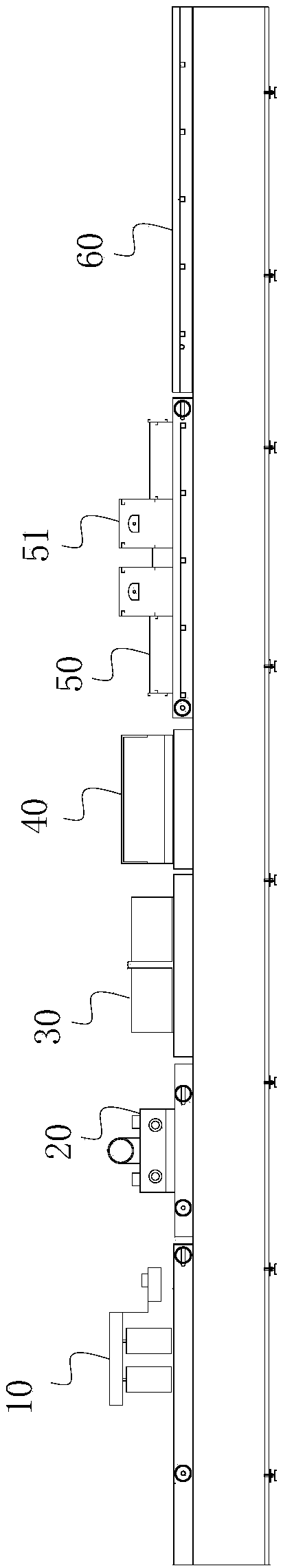

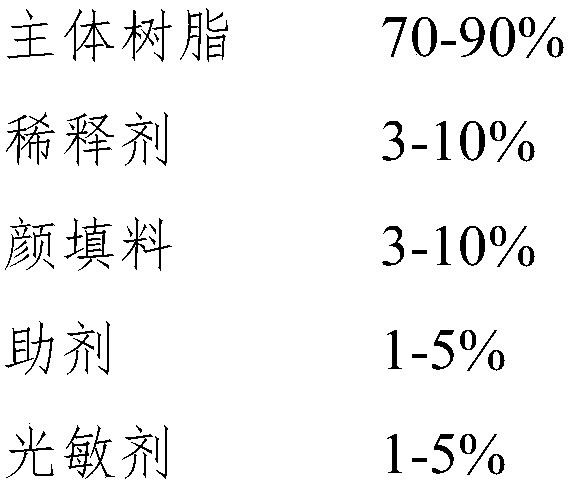

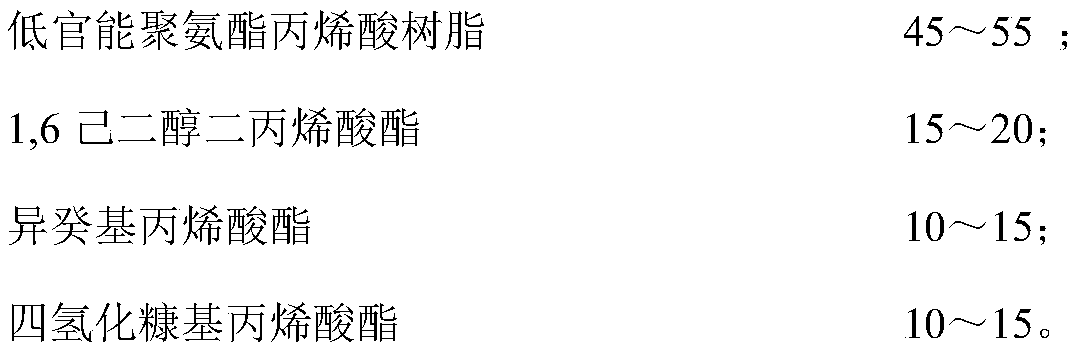

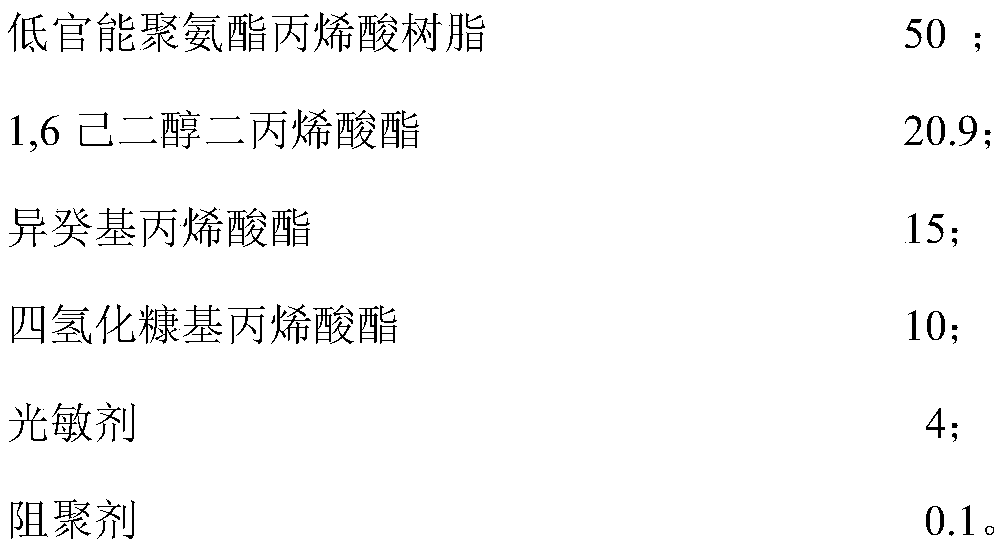

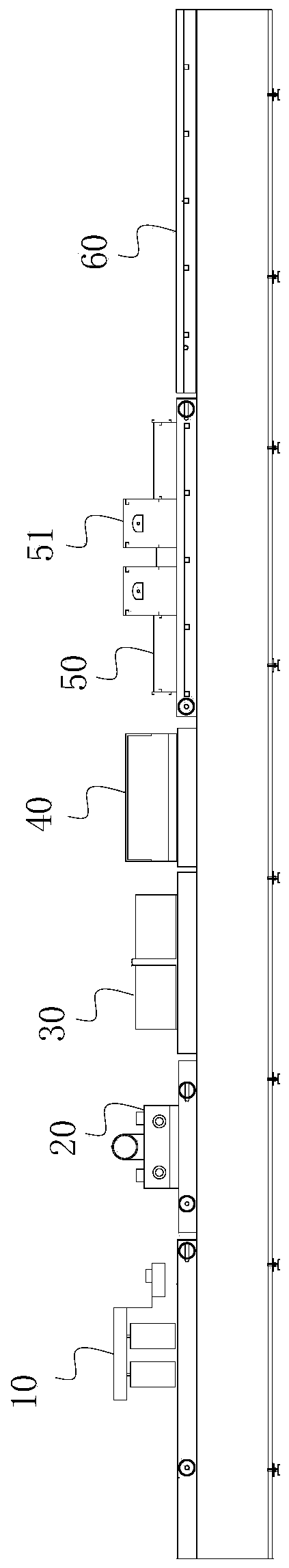

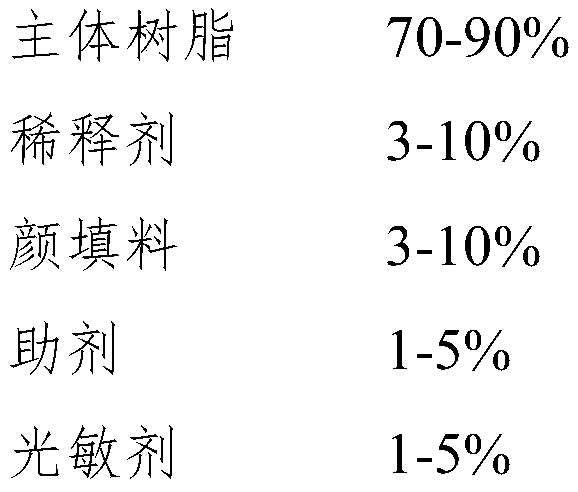

Metal template coating, preparation method thereof and coating production line thereof

ActiveCN107652871ANo side effectsImprove bindingLiquid surface applicatorsAntifouling/underwater paintsTripropylene glycolSodium Bentonite

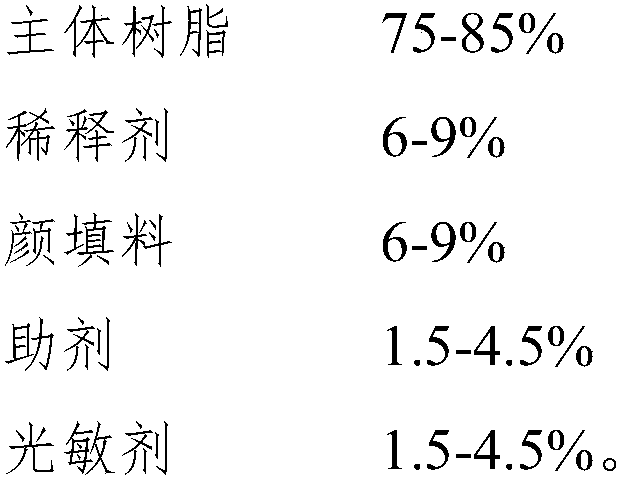

The invention discloses a metal template coating which is composed of, by weight, 70-90% of main resin, 3-10% of diluent, 3-10% of pigment and filler, 1-5% of auxiliary and 1-5% of photosensitive agent. The main resin is selected from one or multiple of aliphatic polyurethane acrylate, acrylate or aromatic methyl semi-acrylate, the diluent is selected from one or multiple of isobornyl acrylate, 1,6-hexanediol diacrylate or tripropylene glycol diacrylate, the pigment and filler comprises 20-30% of zinc stearate, 20-30% of bentonite, 20-30% of calcium carbonate and 20-30% of talcum powder, theauxiliary is selected from one or multiple of polysiloxane, unsaturated polyamide and hydroxyl acid salt or propylene glycol methyl ether, and the photosensitive agent is selected from one or multipleof 1-hydroxy cyclohexylphenyl ketone, 2-isopropyl thioxanthone or 2-benzyl-dimethyl amino-1-(4-morpholine phenyl) butanone.The preparation method does not need a curing agent, and momentary drying within 10s can be realized through ultraviolet curing. The metal template coating is powerful in bonding with an aluminum alloy template and less prone to shedding.

Owner:BEIJING GREEN CHINA TECHNOLOGIC DEV

Corrosion-resistant coating for metal lamp post and preparation method of corrosion-resistant coating

InactiveCN103773148ASuitable for paintingImprove anti-corrosion performanceAnti-corrosive paintsPolyester coatingsPhosphorous acidAcrylic resin

The invention provides a corrosion-resistant coating for a metal lamp post and a preparation method of the corrosion-resistant coating. The coating contains the following components in parts by mass: 8-18 parts of petroleum resin, 0.5-2 parts of alkyd resin, 10-18 parts of acrylic resin, 3-12 parts of dibutyl phthalate, 0.5-1.1 parts of triphenyl phosphite, 10-20 parts of dimethylbenzene, 23-35 parts of ethyl acetate, 3-5 parts of talcum powder, 0.2-0.4 part of maleic acid, 8.7-15 parts of pigment, 3-9 parts of kaolin, 5-13 parts of aluminum oxide and 1.5-4 parts of ultraviolet light absorber. The coating provided by the invention has excellent corrosion resistance, waterproofness, salt fog resistance, wear resistance, rustproofness and aging resistance and is good in recoating and repairing performances, convenient to maintain and very suitable for coating the metal lamp post.

Owner:南通钰成光电科技有限公司

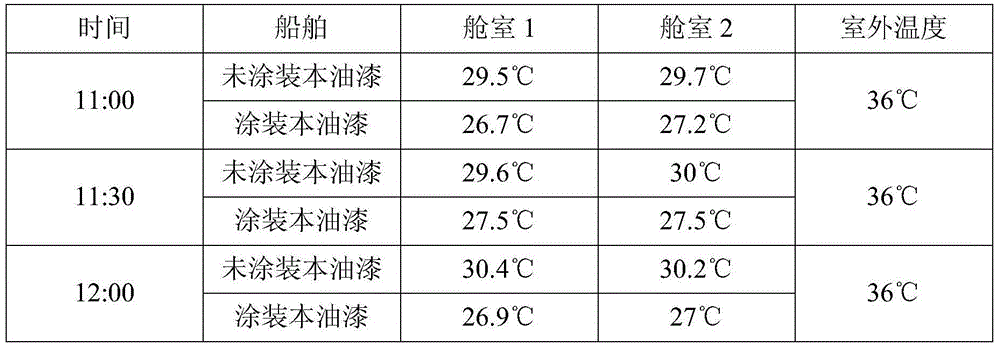

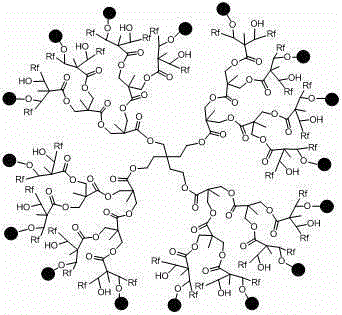

High-corrosion-resistant coating prepared from nano-silica loaded hyperbranched fluroresin

ActiveCN103897572AHigh hardnessExcellent resistance to seawater immersionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

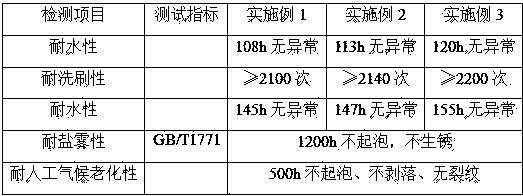

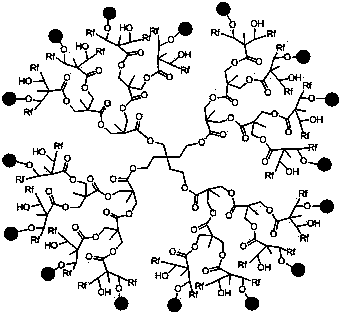

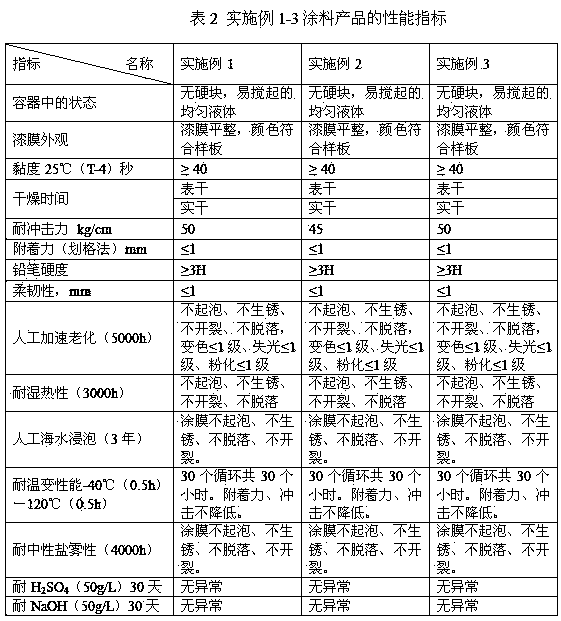

The invention discloses a high-corrosion-resistant coating prepared from nano-silica loaded hyperbranched fluroresin. The coating is prepared by mixing a component A and a component B according to the mass ratio of (8-11):1, wherein the component A is formed by mixing a main material and auxiliary materials, the main material is nano-silica loaded hyperbranched fluroresin, and the auxiliary materials include a mixed solvent, a flatting agent, a catalyst, pigment and filler; the component B is one of a mixture of HDI (Hexamethylene Diisocyanate) biuret and HDI tripolymer. The coating disclosed by the invention has excellent performances such as weather resistance, seawater soaking resistance, damp and hot resistance, temperature change resistance, salt fog resistance, pollution resistance and the like and can resist to the corrosion of a marine environment for a long term; in addition, the service life of a film can be up to more than 25 years after the coating is coated. The preparation method of the high-corrosion-resistant coating disclosed by the invention is simple in operation and low in equipment cost.

Owner:湘江涂料科技有限公司

Method for preparing solvent-type organosilicon waterproof liquid

InactiveCN1962805AImprove permeabilityEasy to recoatOther chemical processesSolventBuilding material

The invention discloses a preparing method of solvent-typed organic silicon water-proof liquid, which comprises the following steps: blending active organic silicane, active organic silicon oil and active organic silicon resin to stir evenly; aerating N2 for 20-40min; adding organic solvent under N2 to mix 20-40min; adding catalyst; forming pre-mixture; stirring the premixture for 0.5-1h to age; packing protected by nitrogen to obtain the product.

Owner:陈俊光

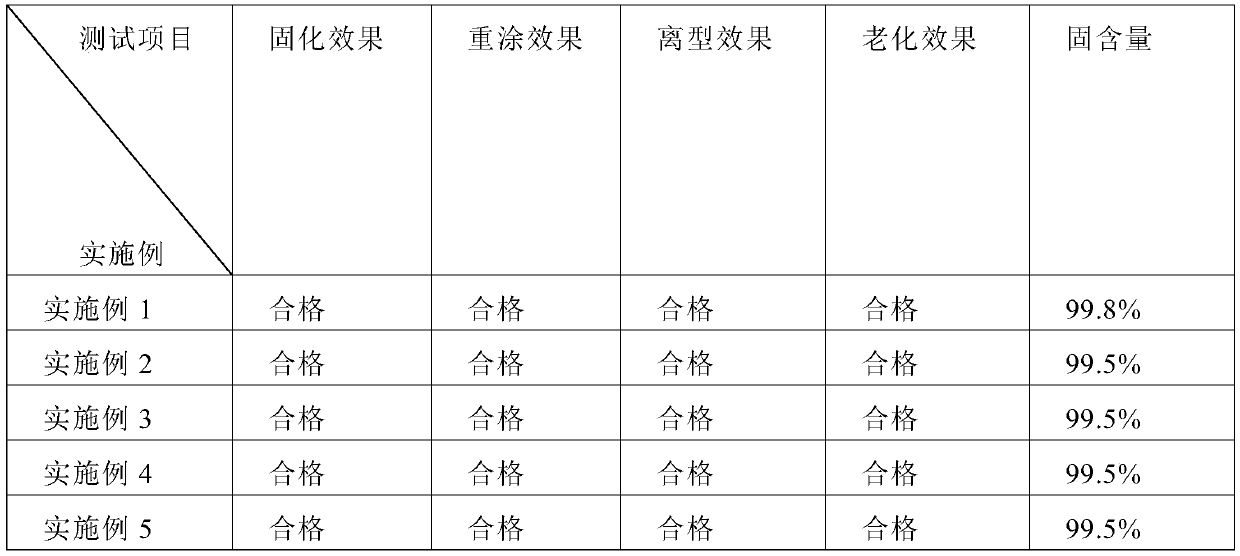

High-tensile UV transfer printing adhesive used for 3.5D and application thereof

InactiveCN111303826AStrong adhesionGood flexibilityPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsScreen printingAdhesive

The invention relates to the field of ink, specifically to a special UV transfer printing adhesive for transfer printing of nanometer fine lines on 3.5D high-tensile PC + PMMA composite boards and screen printing color ink of the 3.5D high-tensile PC + PMMA composite boards and an application of the special UV transfer printing adhesive. The objective of the invention is to provide a high-tensileUV transfer printing adhesive used for 3.5D and an application thereof. The high-tensile UV transfer printing adhesive is a UV light-cured transfer printing adhesive which is UV light-cured, easy to recoat, excellent in toughness, high in tensile strength and good in resistance, and aims to solve the problem that a conventional UV transfer printing adhesive is incapable of being used for the high-tensile requirement of post-processing of 3.5D due to low tensile strength. The UV transfer printing adhesive provided by the invention has a viscosity of 300-600 CPS at a room temperature of 25 DEG C, is high in adhesive force and excellent in flexibility, can realize transfer printing of various nanometer fine lines according to the requirements of customers, and gives people beautiful texture and rich visual effects.

Owner:东莞市瑞辉新材料技术有限公司

UV gloss oil as well as preparation method and application thereof

InactiveCN111171705AGood release effectGood recoatabilityPolyurea/polyurethane coatingsTripropylene glycolPolymer science

The invention relates to UV gloss oil as well as a preparation method and application thereof. The gloss oil is prepared from the following raw materials in percentage by weight: 25-50% of oligomer, 39%-60% of a monomer, 5-8% of a leveling agent, and 3-6% of a photoinitiator; wherein the number of functionalities of the oligomer is 2-3, the leveling agent is selected from a cellulose acetate leveling agent, and the monomer is selected from one or more of trimethylolpropane triacrylate, tripropylene glycol diacrylate and 1,6-hexanediol diacrylate. In the UV gloss oil provided by the invention,the oligomer is used as one of main film-forming raw materials, wherein the functionality number of the oligomer is adjusted, and the oligomer is matched with the monomer for use, so that a paint filmformed by the prepared gloss oil has a relatively good release effect and a relatively good recoating effect; in addition, cellulose acetate substances are used as the leveling agent, so that the gloss oil has a good leveling effect, and the release effect of a paint film formed by the gloss oil can be further improved.

Owner:山东布瑞特油墨有限公司

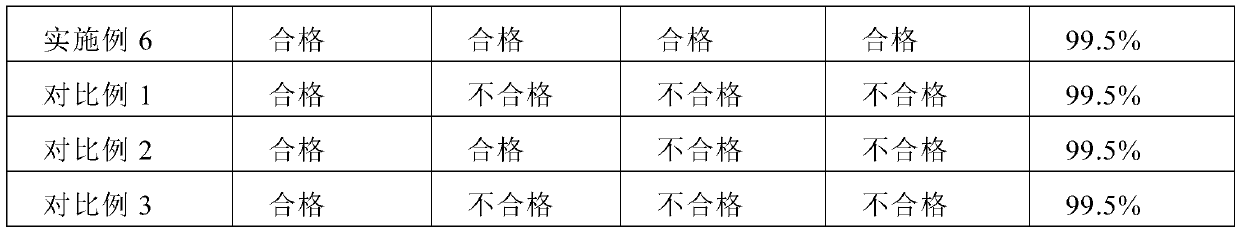

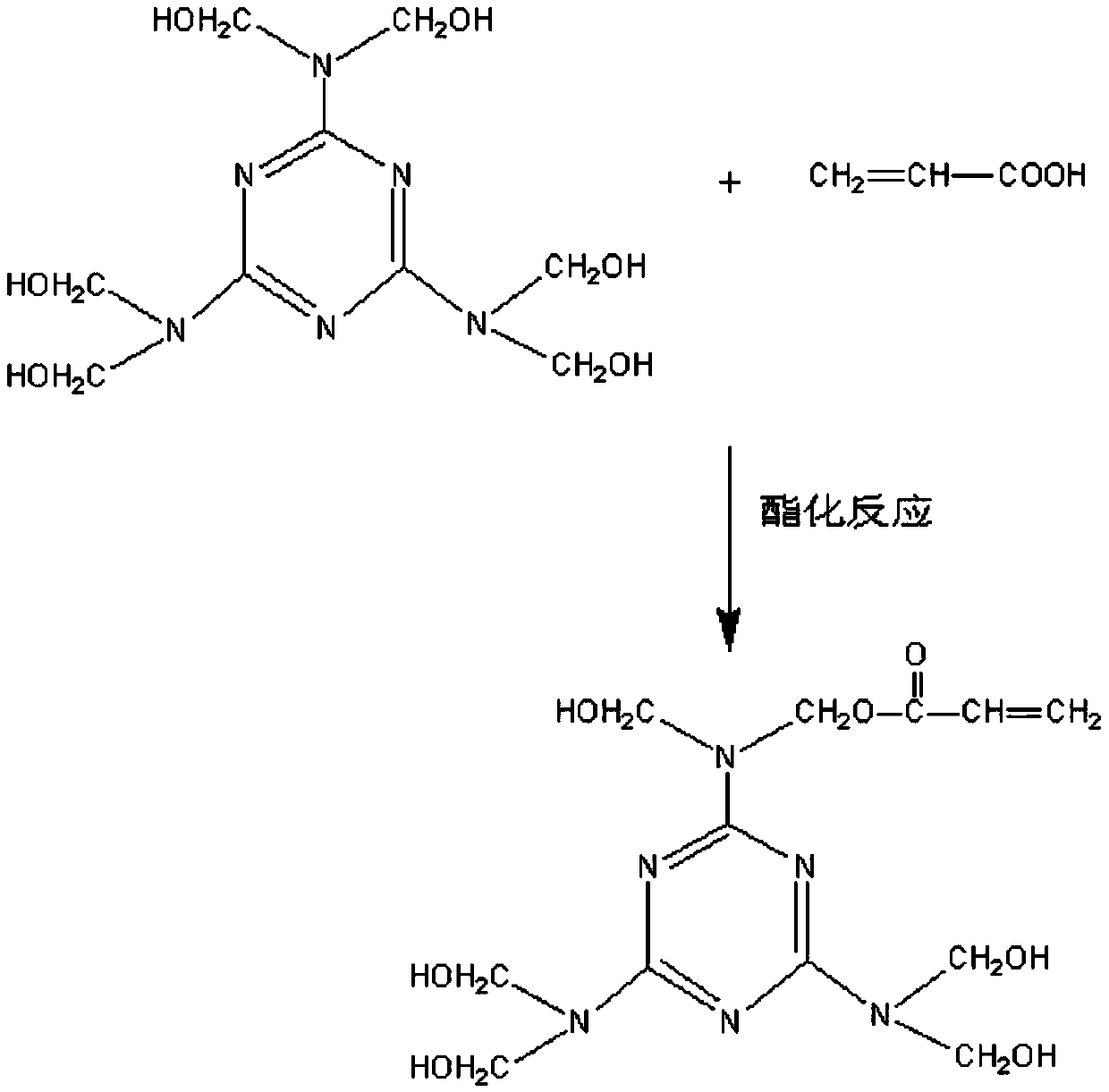

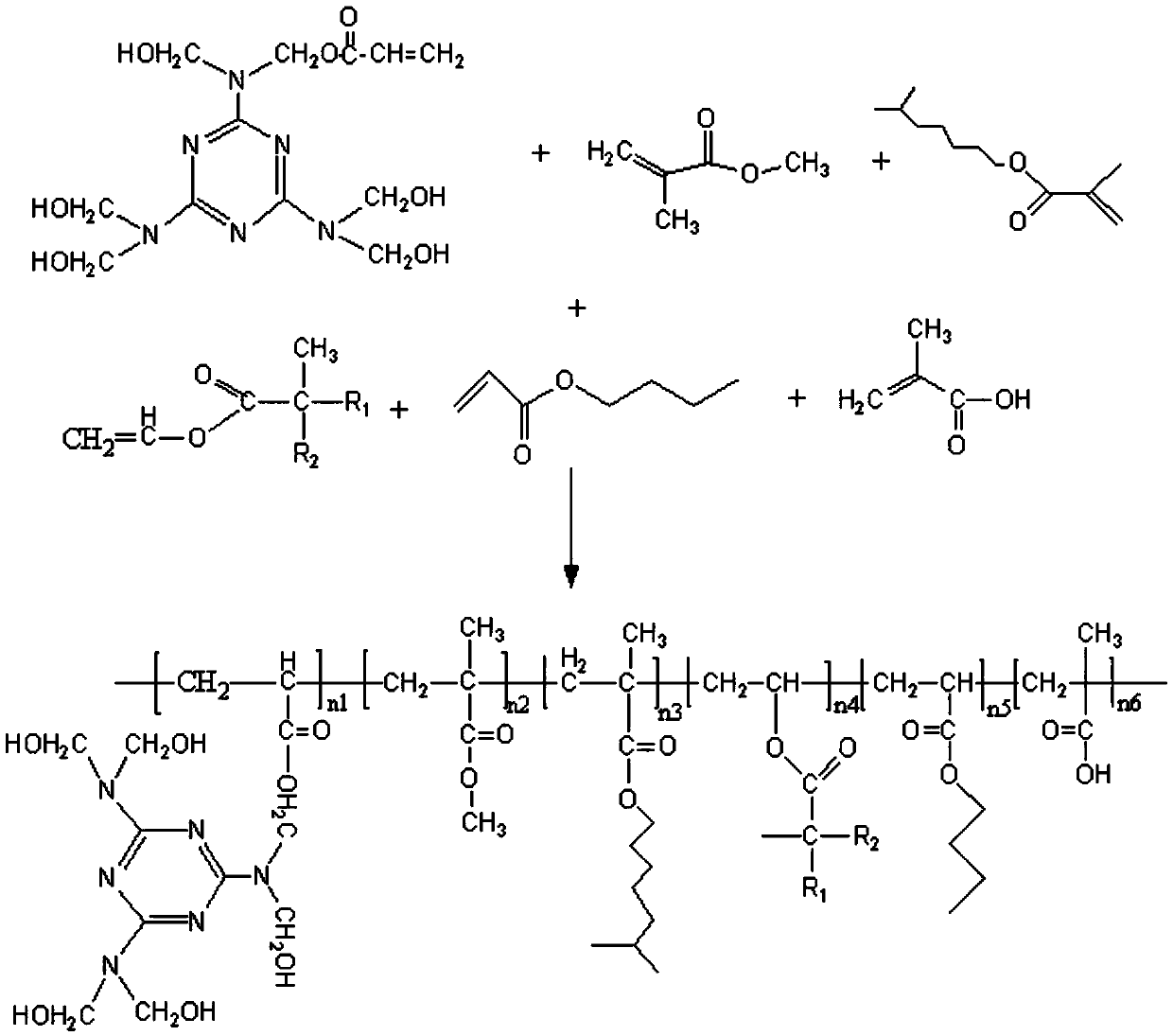

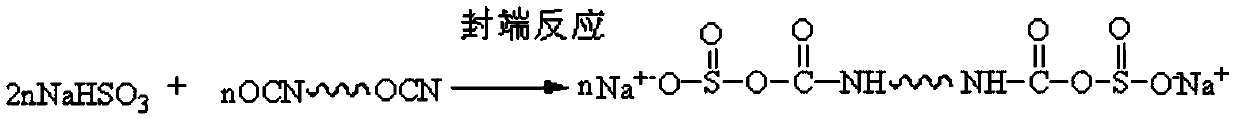

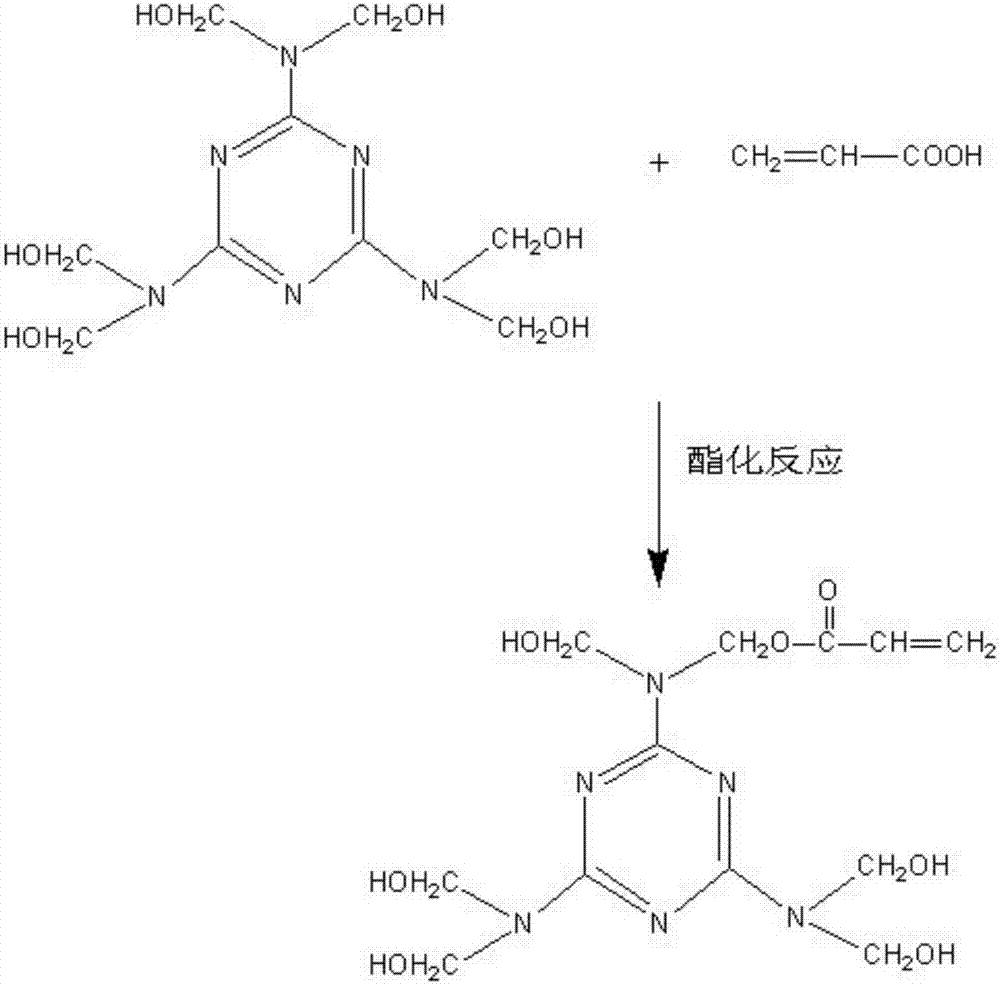

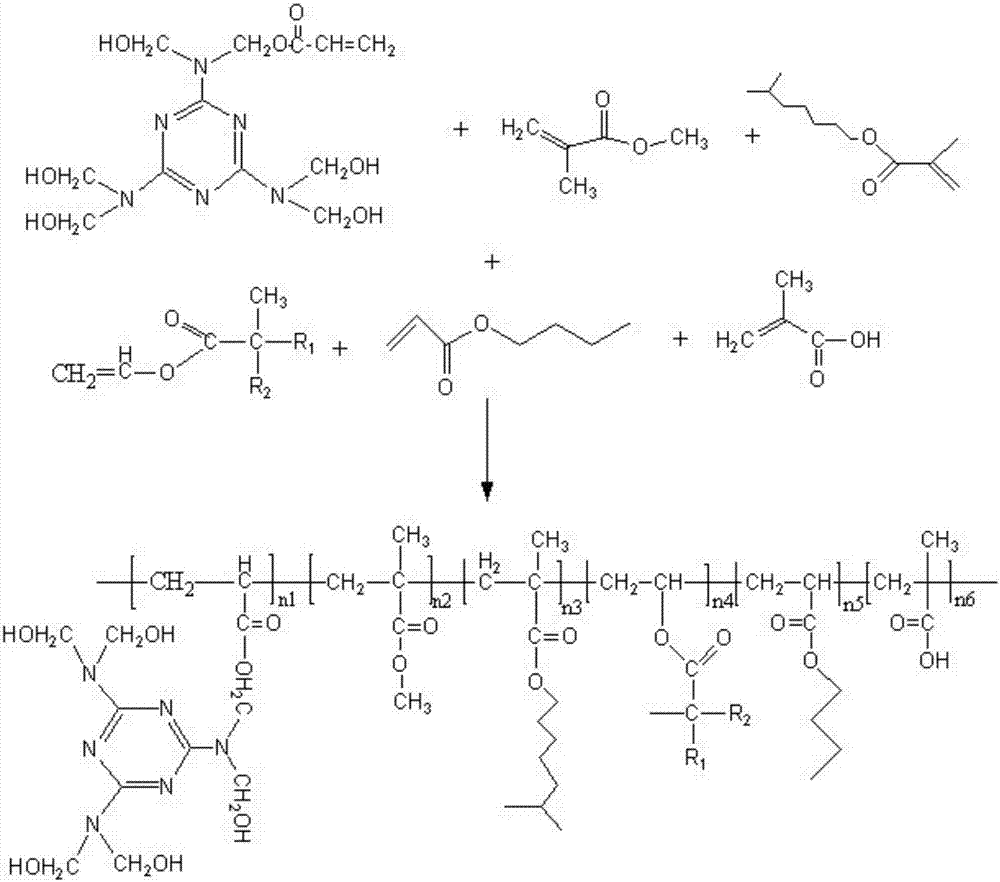

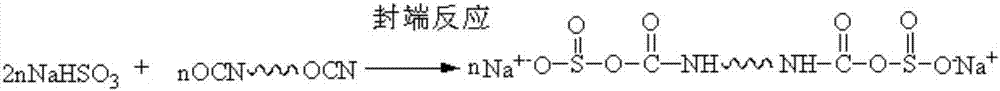

Preparation method of low-temperature curing type waterborne amino acrylic resin

InactiveCN105504145ACorrosion resistanceLow curing temperatureAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinLow temperature curing

The invention discloses a preparation method of low-temperature curing type waterborne amino acrylic resin. The preparation method comprises the following steps of performing esterification reaction on melamine formaldehyde resin and acrylic acid to obtain an amino acrylic ester macromonomer; mixing the amino acrylic ester macromonomer into an acrylic monomer emulsion, and polymerizing to obtain a polyamino acrylic ester emulsion; mixing the polyamino acrylic ester emulsion and water-soluble blocked isocyanate, so as to prepare the low-temperature curing type waterborne amino acrylic resin. The preparation method has the advantages that the melamine formaldehyde resin is mixed into the acrylic acid to prepare the amino acrylic ester, and multiple types of acrylic ester are mixed into the amino acrylic ester, so that the properties of the emulsion and a rubber film are improved, the anti-scratching and anti-corrosive properties of a coating film are improved, and the service life of the coating film is prolonged; after the isocyanate which is blocked by sodium bisulfite is used, the self disadvantages are overcome by the advantages of the isocyanate and the acrylic ester, and the coating film has the water-proof, anti-aging and anti-corrosive properties of the amino acrylic ester, and also has the property of low curing temperature of the isocyanate.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

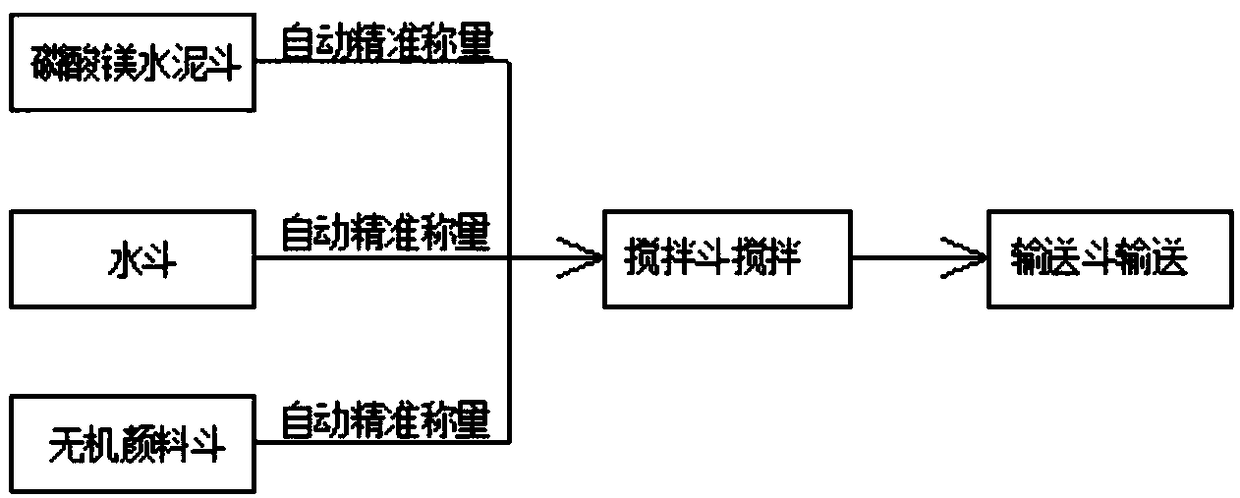

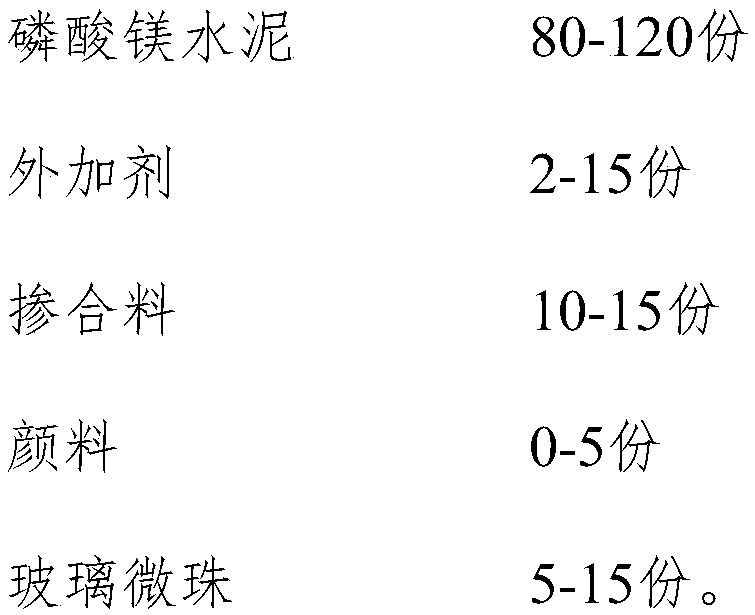

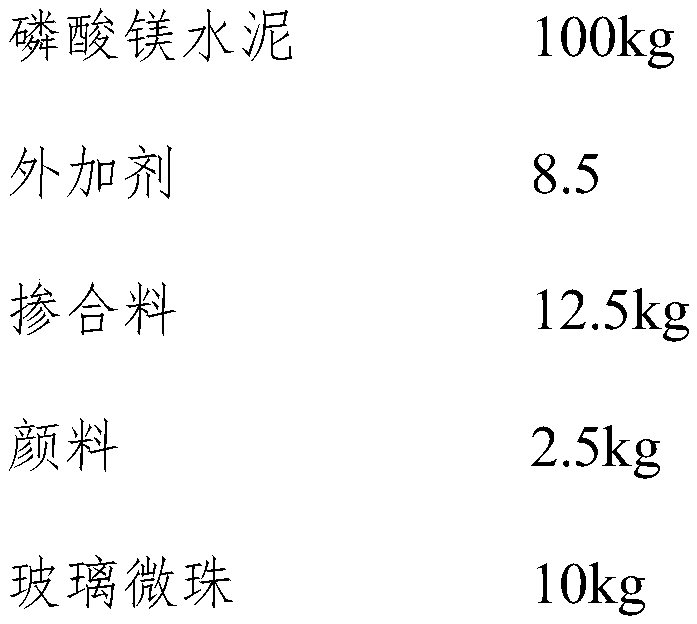

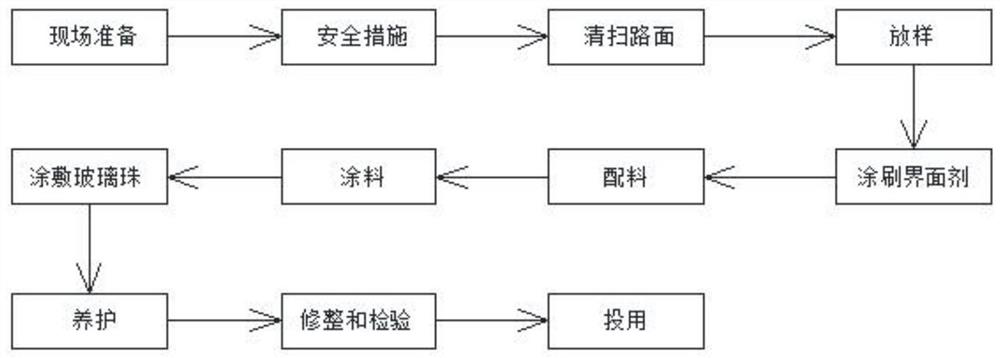

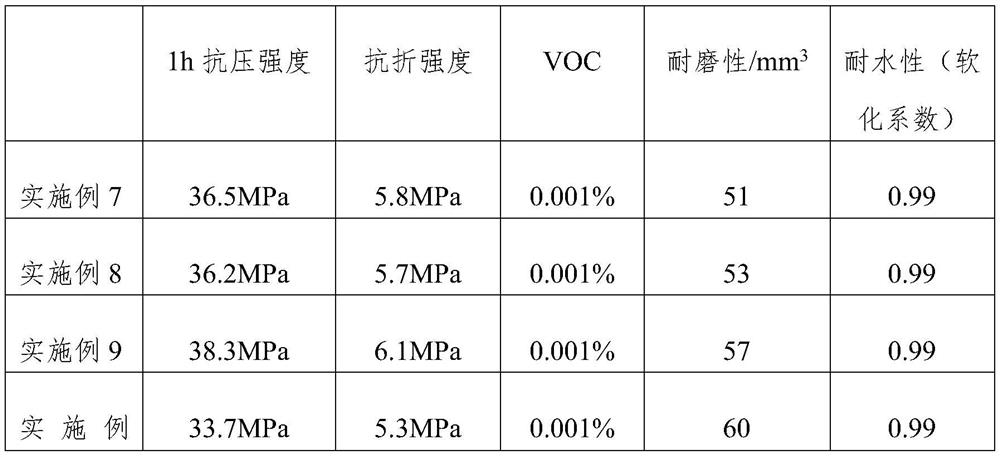

Road lineating material based on phosphorus and magnesium material and preparation method thereof

The invention relates to the technical field of materials, in particular to a road lineating material based on a phosphorus and magnesium material and a preparation method thereof. The road lineatingmaterial based on the phosphorus and magnesium material is prepared by mixing magnesium phosphate cement, an additive, a mixture, a pigment and glass beads in a special proportion. The road lineatingmaterial constructed and coated to a pavement has the comprehensive advantages of excellent permeating wettability, high early strength, high closed adhesive force, quick drying and wear resistance, water logging resistance and solarization resistance, non-slip and convenience in construction, construction at a relatively low temperature, low cost, easy re-coating and the like, and the VOC value of the material is nearly zero. The main body of the material is a water base which is non-combustible and non-explosive and non-toxic and harmless. The road lineating material based on the phosphorusand magnesium material is suitable for low-temperature construction, high in drying speed, high in strength, high in adhesive force and durability, has the advantages of environmental protection, energy conservation, safety and reliability and easy re-coating, and is simple in preparation process and short in consumed time.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

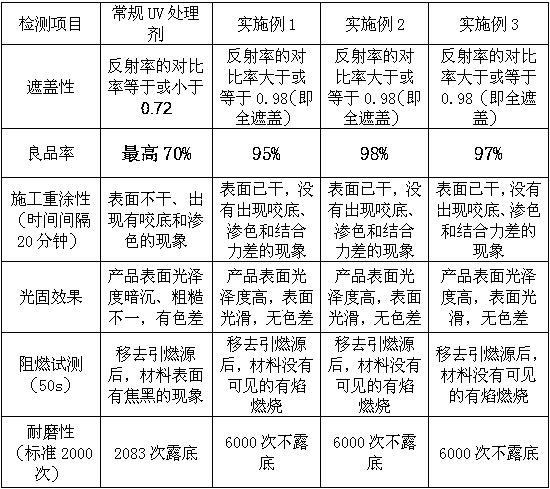

High-shielding UV treatment agent and treatment process thereof

InactiveCN109810627AGuaranteed to be smoothGood dispersion effectPolyurea/polyurethane coatingsPolyester coatingsChemistryPolyester

The invention relates to a high-shielding UV treatment agent and a treatment process thereof. The high-shielding UV treatment agent is prepared from special modified acrylic ester, urethane acrylate,polyester acrylate, modified silicon dioxide, TMP3EOTA, HDDA, Ciba184, TPO, BASF819, leveling agents, butyl cellosolve, methylbenzene, isopropanol, ethyl acetate, butyl acetate and organic silicon leveling agents. A product obtained by using the formula and being treated by the treatment process has the advantages of high shielding performance, high wear performance, easy re-coating, high surfacedrying speed, high curing speed, fast film forming and the like; the problems of bottom hinging, color seepage and poor combination power do not occur after the re-coating; the treated coating surfacehas high smoothness, high luster degree, good smoothness and high qualified product rate, and solves the problems of nonuniform roughness degree, poor shielding performance, poor re-coating effect, construction inconvenience, low qualification product rate and the like of the surface coating of a product treated by the existing conventional UV treatment agent.

Owner:陈建平

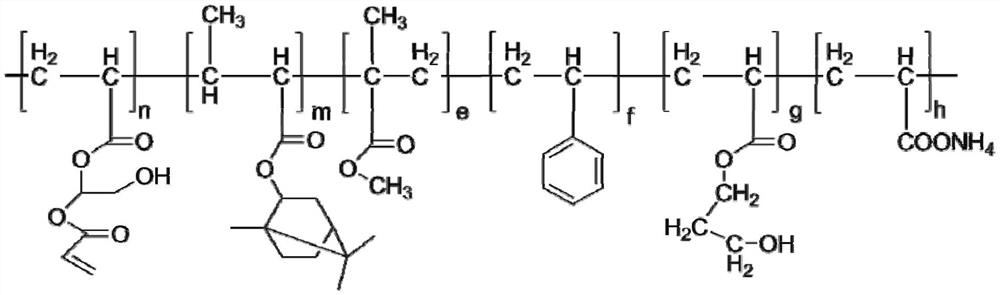

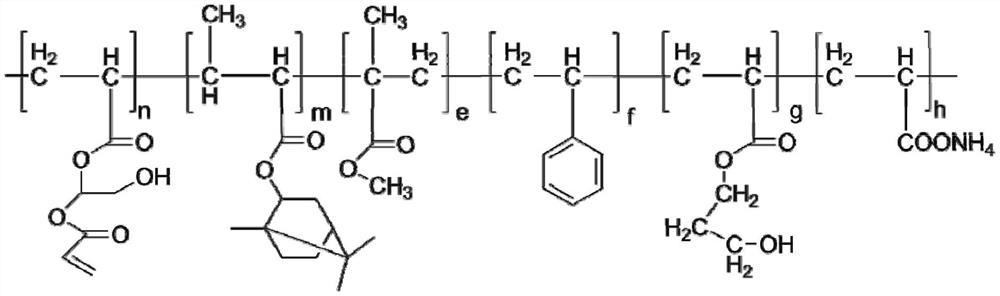

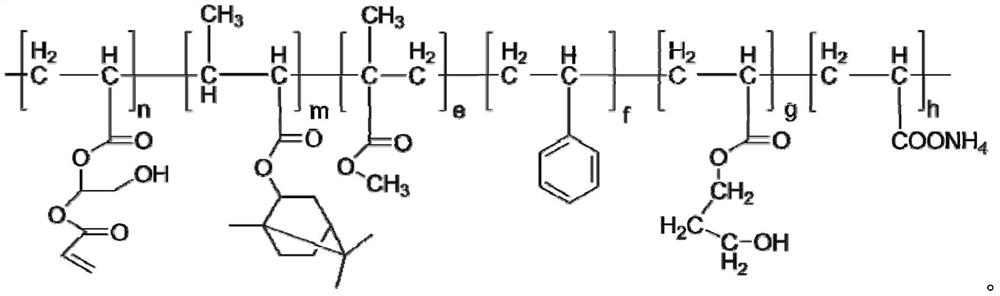

Dual-curing acrylic resin as well as preparation method and application thereof

ActiveCN112920307AImprove performanceIncrease TG valuePolyurea/polyurethane coatingsPolymer scienceGlycidyl methacrylate

The invention discloses dual-curing acrylic resin as well as a preparation method and application thereof. The dual-curing acrylic resin is prepared from the following raw materials: isobornyl methacrylate, acrylic acid, methyl methacrylate, styrene, hydroxyethyl acrylate, an initiator I, a phosphine catalyst, glycidyl methacrylate, a neutralizer and dipentaerythritol pentaacrylate. According to the invention, the dual-curing acrylic resin is formed under the action of the phosphine catalyst through matching of the raw materials; the content of double bonds and hydroxyl groups in the resin is high, and a paint film formed after ultraviolet curing is good in hardness; and the performance of the paint film is further improved through thermocuring.

Owner:湖南松井先进表面处理与功能涂层研究院有限公司

Polysiloxane heat-reflective topcoat and preparation method thereof

InactiveCN104946129AOutstanding resistance to atmospheric agingOutstanding resistance to UV degradationAnti-corrosive paintsReflecting/signal paintsWeather resistanceThermal insulation

The invention provides a polysiloxane heat-reflective topcoat and a preparation method thereof. The polysiloxane heat-reflective topcoat comprises a component A and a component B, and the weight ratio of the component A to the component B is 8:(1-1.5); the component A comprises the following ingredients by weight: 30-40 parts of polysiloxane resin, 3-8 parts of a thermal insulation material, 0.6-0.9 part of a stabilizer, 25-48 parts of a mixed solvent, 0.2-0.5 part of a dispersant, 17-33 parts of an anti-aging pigment and an anti-aging filler, and 0.2-0.5 part of an anti-settling agent; the component B comprises the following ingredients by weight: 60-70 parts of a curing agent and 18-35 parts of a curing agent solvent. The polysiloxane heat-reflective topcoat is high in ageing-resistant performance, weather resistance and chemical resistance, has a heat reflection function, can be suitable for various construction methods, and is good in recoatability and excellent in cost performance; besides, external corrosion protection of the surface of coated steel is achieved, a lot of coating expenditures can be reduced, and the service life is prolonged.

Owner:上海海悦涂料有限公司

A kind of dual curing acrylic resin and its preparation method and application

ActiveCN112920307BImprove performanceIncrease TG valuePolyurea/polyurethane coatingsPolymer scienceGlycidyl methacrylate

The invention discloses a dual-curing acrylic resin and a preparation method and application thereof. The dual-curing acrylic resin comprises the following raw materials: isobornyl methacrylate, acrylic acid, methyl methacrylate, styrene, hydroxyethyl acrylate, initiator Agent I, phosphine catalyst, glycidyl methacrylate, neutralizer and dipentaerythritol pentahexaacrylate. The invention forms a dual-curing acrylic resin under the action of a phosphine catalyst through the combination of various raw materials; the double bond and hydroxyl content in the resin are relatively high, and the hardness of the paint film formed after curing by ultraviolet light is good; Further improved film performance.

Owner:湖南松井先进表面处理与功能涂层研究院有限公司

A kind of high anti-corrosion coating prepared with loaded nano-silica hyperbranched fluororesin

ActiveCN103897572BHigh hardnessExcellent resistance to seawater immersionAnti-corrosive paintsPolyurea/polyurethane coatingsWeather resistancePtru catalyst

A high anti-corrosion coating prepared by loading nano silicon dioxide hyperbranched fluororesin. The coating is composed of component A and component B mixed at a mass ratio of 8 to 11:1; component A is composed of main raw materials loaded with nano-silica hyperbranched fluororesin and auxiliary materials mixed solvent, leveling agent, catalyst, pigment The filler is mixed; the second component is one of HDI biuret, HDI trimer or their mixture. The coating of the invention has excellent performances such as weather resistance, seawater immersion resistance, heat and humidity resistance, temperature change resistance, salt spray resistance and stain resistance, and can resist corrosion of marine environment for a long time, and the life of the coating film after one coating can reach more than 25 years. The preparation method of the high anticorrosion paint of the invention has simple operation and low equipment cost.

Owner:湘江涂料科技有限公司

A fast and highly oil-absorbing oil canvas

ActiveCN109403053BEasy to dryHigh oil absorptionOther artistic work equipmentsTextiles and paperMethacrylateGlycerol

The invention provides a fast oil-absorbing oil canvas. The specific steps are: (1) dissolving the glue with deionized water; wherein, the glue is transparent acrylic glue or animal glue; (2) adding titanium dioxide, polymethacrylic acid ten Hexaester, polycarboxylic acid and its salt, ammonium bicarbonate, mixed evenly; among them, the mass ratio of titanium dioxide, polyhexadecyl methacrylate, polycarboxylic acid and its salt to water is 0‑0.1:0.5‑0.7 :0.2‑0.3: 1, (3) Brush the glue mixed solution evenly on the linen cloth, after drying, brush the next layer, the glue layer is 6‑10mm, and finally brush a layer of glycerin; (4) Dry at high temperature. The processing method is simple and convenient, with good oil absorption and no oil bleeding. After multiple times of painting, apply another layer of glycerin to ensure that the oil will not bleed in the later stage.

Owner:上官星

Rapid high-oil-absorbing painting canvas

ActiveCN109403053AGood workmanshipQuality is not affectedOther artistic work equipmentsTextiles and paperMethacrylateGlycerol

The invention provides a rapid high-oil-absorbing painting canvas prepared through the steps of: (1) dissolving gum in deionized water, the gum being transparent acrylic glue or animal glue; (2) adding TiO2, polyhexadecyl methacrylate, polycarboxylic acid and salt thereof, and ammonium bicarbonate to the glue, and uniformly mixing the components, wherein the mass ratio of the TiO2, polyhexadecyl methacrylate, polycarboxylic acid and salt thereof, and water is 0-0.1:0.5-0.7:0.2-0.3:1; (3) uniformly brushing a linen fabric with the mixed glue solution, after the present layer is dried, brushingthe linen fabric with the next layer, until the glue layer is 6-10 mm in thickness, and finally brushing the fabric with a layer of glycerol; (4) drying the fabric at high temperature. The preparationmethod is simple and convenient. The painting canvas has great oil absorbency and is free of seepage of oil, and is free of oil seepage in later period by brushing the painting canvas with a layer ofglycerol after painting for several times.

Owner:上官星

Synthetic emulsion diatom interior wall latex paint and preparation method thereof

ActiveCN105176220BEasy constructionReduce construction costsAnti-corrosive paintsEmulsion paintsAnti freezingEmulsion

The invention discloses synthetic latex diatom inner wall emulsion paint and a preparation method thereof. The inner wall emulsion paint is prepared from, by weight, 260-300 parts of polymer emulsion, 1-5 parts of hydroxyethyl cellulose, 200-220 parts of diatomite, 10-25 parts of anti-freezing agents, 15-17 parts of film-forming auxiliaries, 1-5 parts of thickeners, 1-5 parts of flatting agents, 4-8 parts of wetting dispersants, 1-5 parts of defoaming agents, 60-120 parts of filler and 300-315 parts of water. The PVC / CPVC of the emulsion paint is 1.1-1.3. The PVC is the pigment size concentration of the emulsion paint, and the CPVC is the critical pigment volume concentration of the emulsion paint. The inner wall emulsion paint has water resistance, washability and air permeability at the same time, and the diatomite can effectively release anions.

Owner:ZHANG ZHOU SAN PAINTS +1

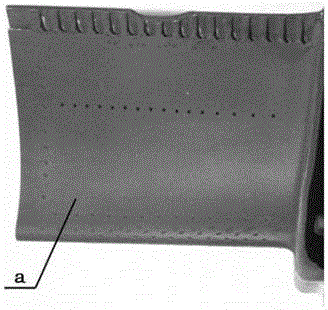

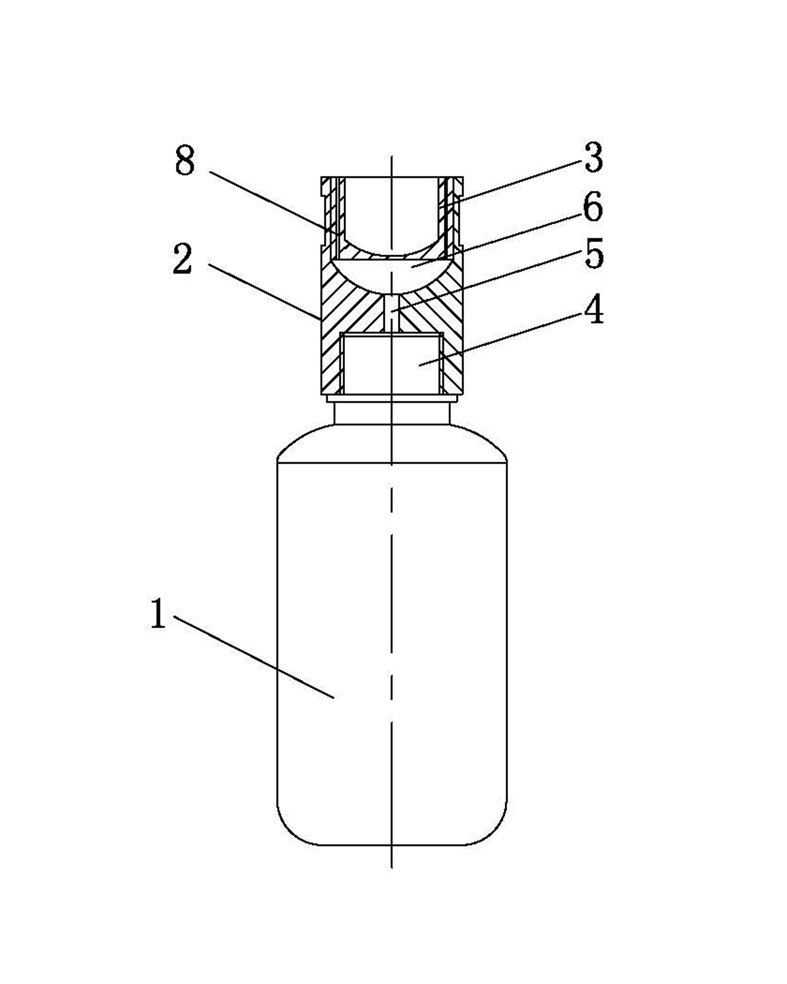

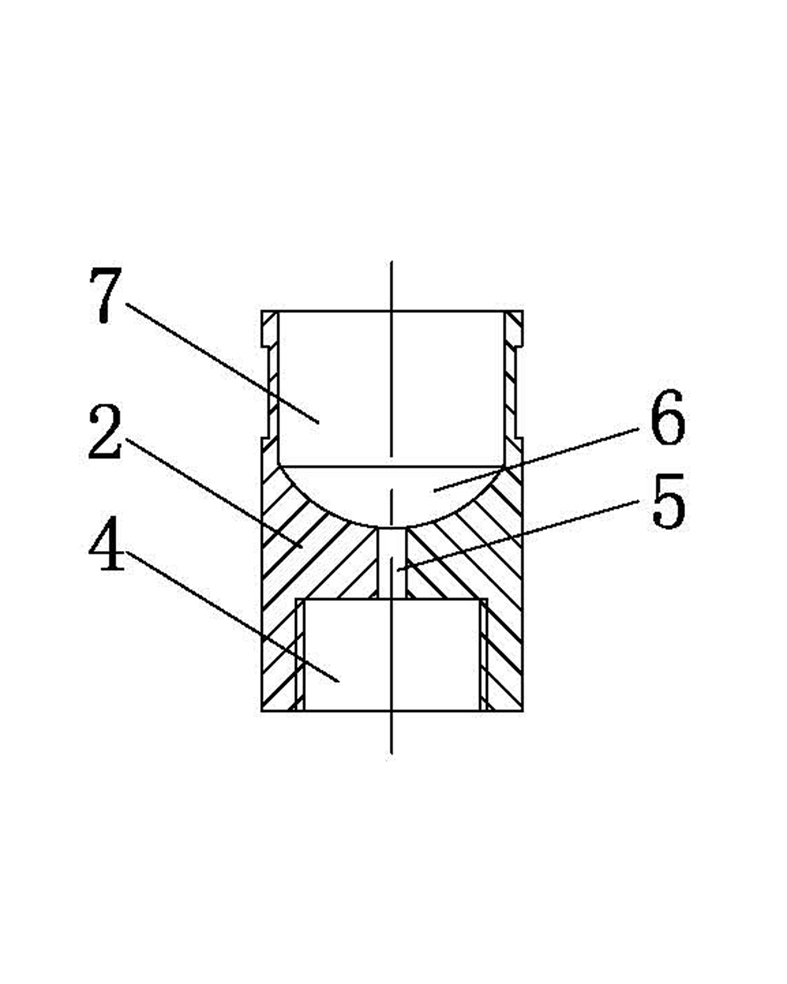

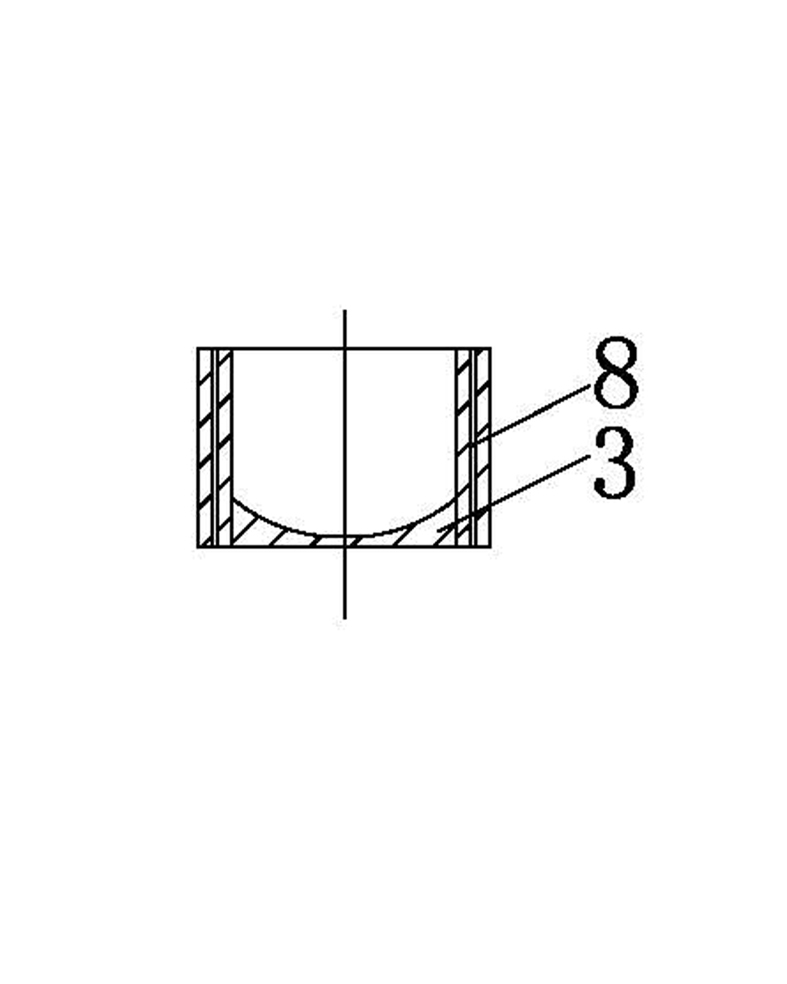

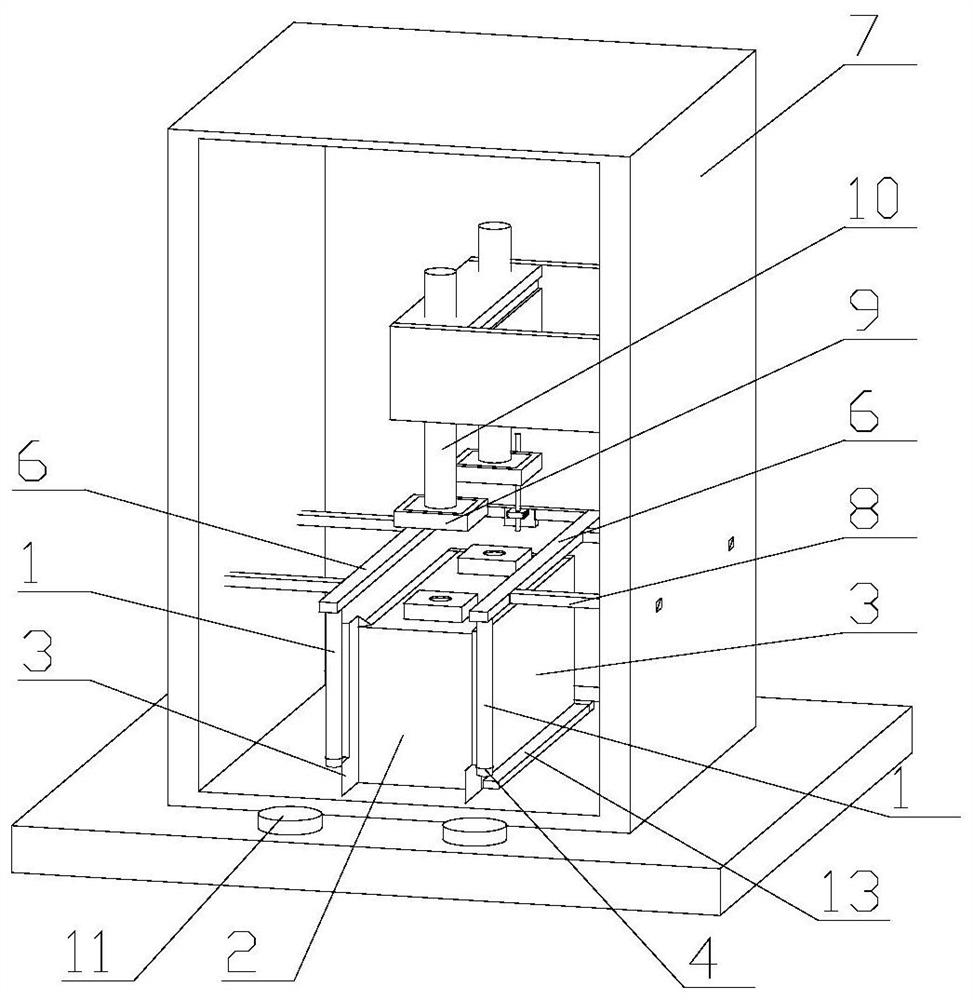

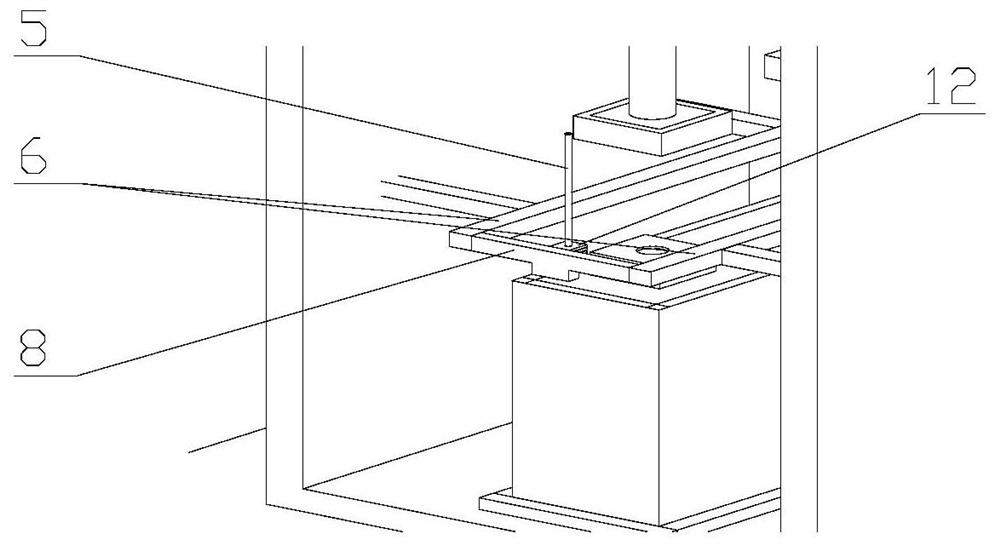

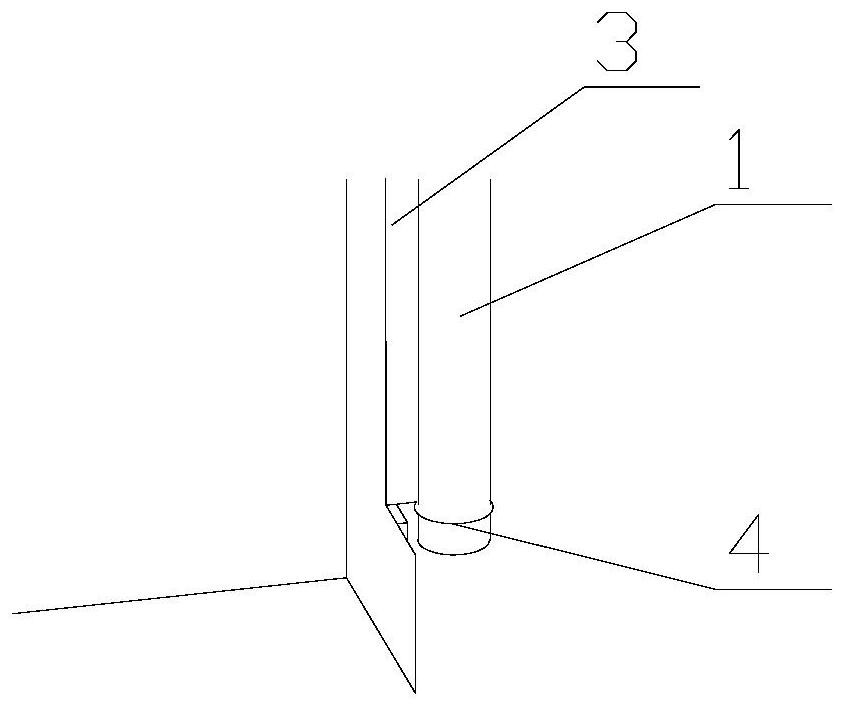

Supplementary coating device for metal tank welding lug

ActiveCN102019261AEasy to recoatControl the amount of recoatingLiquid surface applicatorsCoatingsEngineeringFiber

The invention relates to a supplementary coating device for a metal tank welding lug. The device comprises an elastic bottle body, a connecting piece and a cover, wherein the connecting piece is arranged on the upper part of the elastic bottle body; the cover is arranged on the upper part of the connecting piece; a flow guide hole is formed in the connecting piece; and a coating material hole is formed on the upper peripheral wall of the cover; the flow guide hole is communicated with the coating material hole; and the coating material hole is covered by a shielding member which is made of a material of fibrous tissue. Through the device, the problem of low supplementary coating speed of manual coating is solved, the supplementary coating amount can be more easily controlled in a supplementary coating process, and the difficulty of a subsequent drying step is reduced; meanwhile, the phenomenon that a dirty product occurs is effectively controlled, so the product quality is effectivelyimproved.

Owner:SUZHOU HYCAN HLDG CO LTD

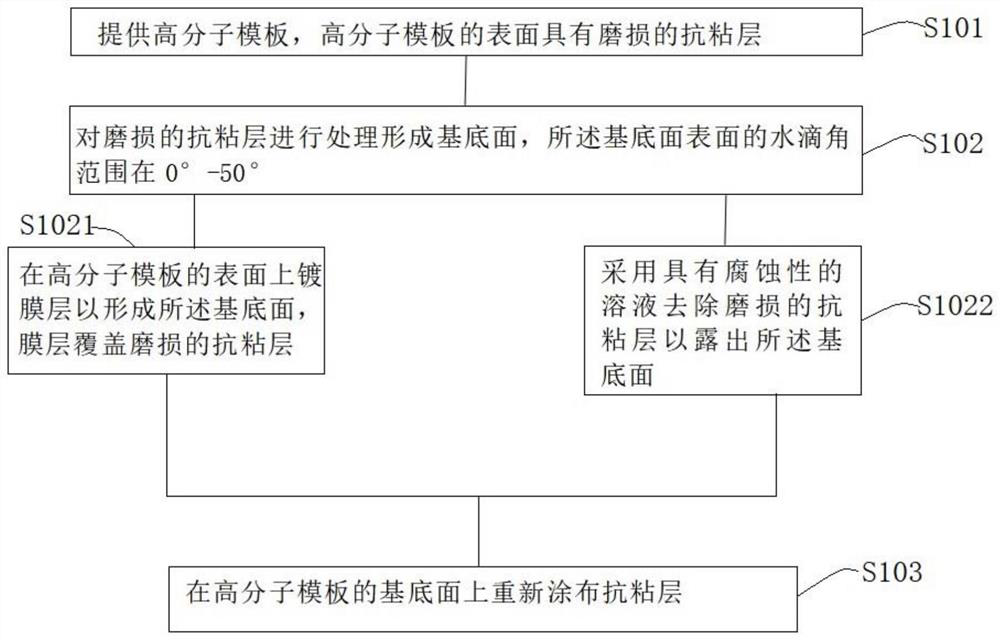

Polymer template surface treatment method

PendingCN114236963AEasy to recoatImprove wettabilityPhotomechanical apparatusPolymer scienceAqueous droplet

The invention discloses a polymer template surface treatment method. The polymer template surface treatment method comprises the following steps: providing a polymer template, wherein the surface of the polymer template is provided with a wear-resistant anti-sticking layer; the abraded anti-sticking layer is treated to form a substrate surface, and the water drop angle of the surface of the substrate surface ranges from 0 degree to 50 degrees; the method comprises the following steps: coating a film layer on the surface of a polymer template to form the substrate surface, and covering a worn anti-sticking layer with the film layer; or removing the abraded anti-sticking layer by adopting a corrosive solution so as to expose the substrate surface; and re-coating the anti-sticking layer on the substrate surface of the polymer template.

Owner:GOERTEK INC

Preparation method of low-temperature curing water-based aminoacrylic acid resin

InactiveCN105504145BCorrosion resistanceLow curing temperatureAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinLow temperature curing

The invention discloses a preparation method of low-temperature curing type waterborne amino acrylic resin. The preparation method comprises the following steps of performing esterification reaction on melamine formaldehyde resin and acrylic acid to obtain an amino acrylic ester macromonomer; mixing the amino acrylic ester macromonomer into an acrylic monomer emulsion, and polymerizing to obtain a polyamino acrylic ester emulsion; mixing the polyamino acrylic ester emulsion and water-soluble blocked isocyanate, so as to prepare the low-temperature curing type waterborne amino acrylic resin. The preparation method has the advantages that the melamine formaldehyde resin is mixed into the acrylic acid to prepare the amino acrylic ester, and multiple types of acrylic ester are mixed into the amino acrylic ester, so that the properties of the emulsion and a rubber film are improved, the anti-scratching and anti-corrosive properties of a coating film are improved, and the service life of the coating film is prolonged; after the isocyanate which is blocked by sodium bisulfite is used, the self disadvantages are overcome by the advantages of the isocyanate and the acrylic ester, and the coating film has the water-proof, anti-aging and anti-corrosive properties of the amino acrylic ester, and also has the property of low curing temperature of the isocyanate.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A road marking material and construction method based on phosphorus and magnesium materials

ActiveCN108751925BHigh strengthControllable solidification timeTraffic signalsRoad signsMagnesium phosphateMagnesium orthophosphate

The invention relates to the technical field of traffic and in particular relates to a road marking material based on a phosphorus magnesium material and a construction method. The road marking material is composed of a phosphorus magnesium material and glass beads, and comprises the following components in parts by weight: 80-120 parts of magnesium phosphate cement, 2-15 parts of an admixture, 10-15 parts of an additive, 0-5 parts of inorganic pigments and 5-15 parts of glass beads. The construction method comprises the following steps: brushing with an adhesion agent, batching, coating marking, applying the glass beads and curing. The material disclosed by the invention has the advantages of being excellent in penetrating wettability, high in early strength, high in sealing adhesion force, quick-drying, wear-resistant, water-resistant, sun-proof, difficult to skid, convenient in construction, low in cost, easy for re-coating, simple in preparation, energy-saving and energy-saving.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

Battery film tearing device and method

ActiveCN112249453AImprove convenienceReduce difficultyFinal product manufactureUnpacking by cuttingElectrical batteryMechanical engineering

The invention relates to the technical field of battery production equipment, and provides a battery film tearing device and method. The battery film tearing device comprises two film tearing units and a cutting unit, wherein the two film tearing units are arranged to be fixed to the first tearing end and the second tearing end of an insulating film torn from one end of a battery respectively so as to tear the insulating film on the side part of the battery from the two sides of the battery in the length direction of the battery respectively; and the cutting unit is arranged to be capable of cutting the insulating film in the film tearing process of the two film tearing units so as to separate the insulating film at the bottom of the battery from the insulating film on the side part of thebattery. According to the battery film tearing device and method, the film tearing speed and the film tearing efficiency can be effectively improved, the convenience of film tearing is realized, thedifficulty of manual film tearing is reduced, the problems of battery collision and shell scratching caused by manual film tearing at present are solved, the secondary rework efficiency is improved, and subsequent film re-coating is facilitated.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Metal stencil coating and preparation method thereof, metal stencil coating production line

ActiveCN107652871BNo side effectsImprove bindingLiquid surface applicatorsAntifouling/underwater paintsTripropylene glycolPolymer science

Owner:BEIJING GREEN CHINA TECHNOLOGIC DEV

Water-based alkyd amino high blackness and high gloss intermediate paint and preparation method thereof

The invention discloses a water-based alkyd amino high blackness and high gloss intermediate paint and a preparation method thereof. The intermediate paint comprises the following raw materials in percentage by weight: water-based alkyd resin 50-70%, dispersant 0.5-2%, defoam agent 0.2-0.5%, carbon black 1-3%, wetting agent 0.1-0.3%, level agent 0.1-0.4%, amino resin 10-16%, pH regulator 1.5-3.5%,cosolvent 3-5%, deionize water 10-20%. 30% of that water-based alkyd resin in the formula is taken, slowly added into a paint mix tank, pH adjustment is added according to 5% of the mass fraction ofthe added water-based alkyd resin under the stirring state of 300r / min, and the mixture is dispersed for 10-15min, 3% of cosolvent and 8% of deionized water are added under the stirring state of 300r / min, and and the mixture is dispersed for 10-15 min, then dispersant is added and a part of defoam agent is added, the stirring speed is increased slowly to 500r / min, and the stirring lasts for 30min. The coating is a single-component coating, and after coating, it is dried through 120-140 DEG C baking at medium and low temperature for about 60 minutes, finally a crosslinked network structure isformed, which is more than double the efficiency of solvent-based coatings currently used.

Owner:节昌澎

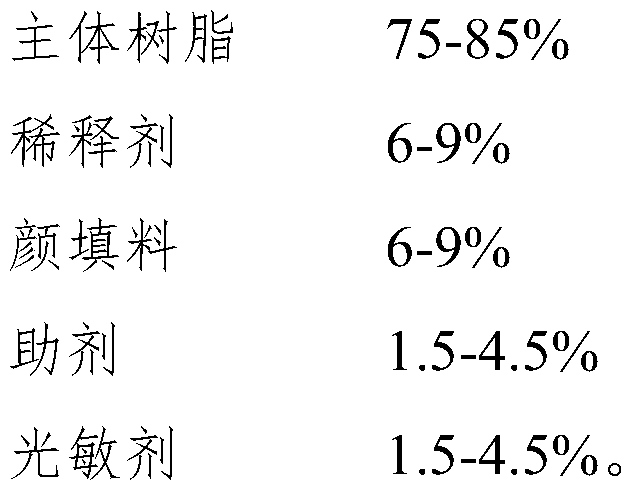

UV-cured high-surface-tension gloss oil and preparation method and application thereof

InactiveCN112552758AIncrease surface tensionImprove adhesionPaper coatingPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention provides UV-cured high-surface-tension gloss oil. The UV-cured high-surface-tension gloss oil comprises the following components in parts by weight: 50-60 parts of modified acrylic resin, 30-40 parts of polyurethane acrylic resin, 5-15 parts of benzyl acrylate, 5-10 parts of a photoinitiator and 0.5-2 parts of a wetting aid. According to the invention, the modified acrylic resin HC5110 is matched with the high-hardness resin HP6615, and then matched with the proper monomer and auxiliary additive, and after UV curing, an organic compound with large molecular weight is formed, andmeanwhile, the oil contains chemical bonds with extremely strong polarity, so that the oil has very high surface energy. Tests show that the dyne value of the cured coating is 40 dyn / cm or above, therequirement for high surface tension of the printed coating is met, adhesive force is promoted, and multi-layer recoating is facilitated. The invention further provides a preparation method and application of the UV-cured high-surface-tension gloss oil.

Owner:广东昊辉新材料有限公司

A kind of pressurized alkaline cooking method for removing ceramic layer in thermal barrier coating

The invention discloses a pressurization alkali-boiling method for removing a ceramic layer in a thermal barrier coating. According to the pressurization alkali-boiling method for removing the ceramiclayer in the thermal barrier coating, alkali liquor is used for removing the ceramic layer in the thermal barrier coating; when the ceramic layer is removed, an alpha-Al2O3 layer on the interface ofthe ceramic layer and a metal layer chemically reacts with an alkali solution under a high temperature and a high pressure, so that the ceramic layer is tripped, damage to the metal bottom layer is avoided, and the metal bottom layer does not need to be repaired, so that the procedures are simple, and re-coating of the ceramic layer is facilitated. The pressurization alkali-boiling method can be implemented conveniently and rapidly, the equipment structure is simple, and operation is easy. Compared with a traditional mechanical sand blasting method, the process parameters can be accurately controlled, and the consistency of the product quality is high. It is found through practice that a ceramic layer of a part treated through the method is completely removed and effectively stripped without damaging a metal layer; and the thickness of the metal bottom layer is not changed before and after the ceramic layer is removed.

Owner:AECC AVIATION POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com