Supplementary coating device for metal tank welding lug

A technology for metal cans and welding lugs, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of low production efficiency, poor control and low efficiency, and achieve product quality improvement and easy repainting. amount, the effect of controlling the amount of replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

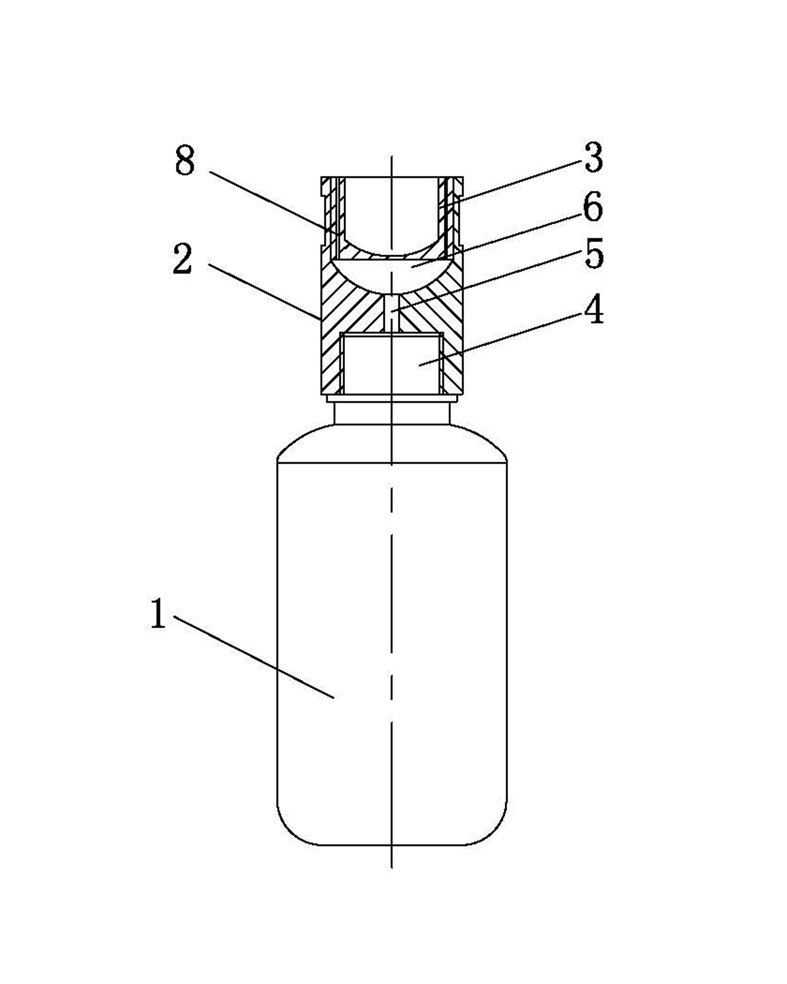

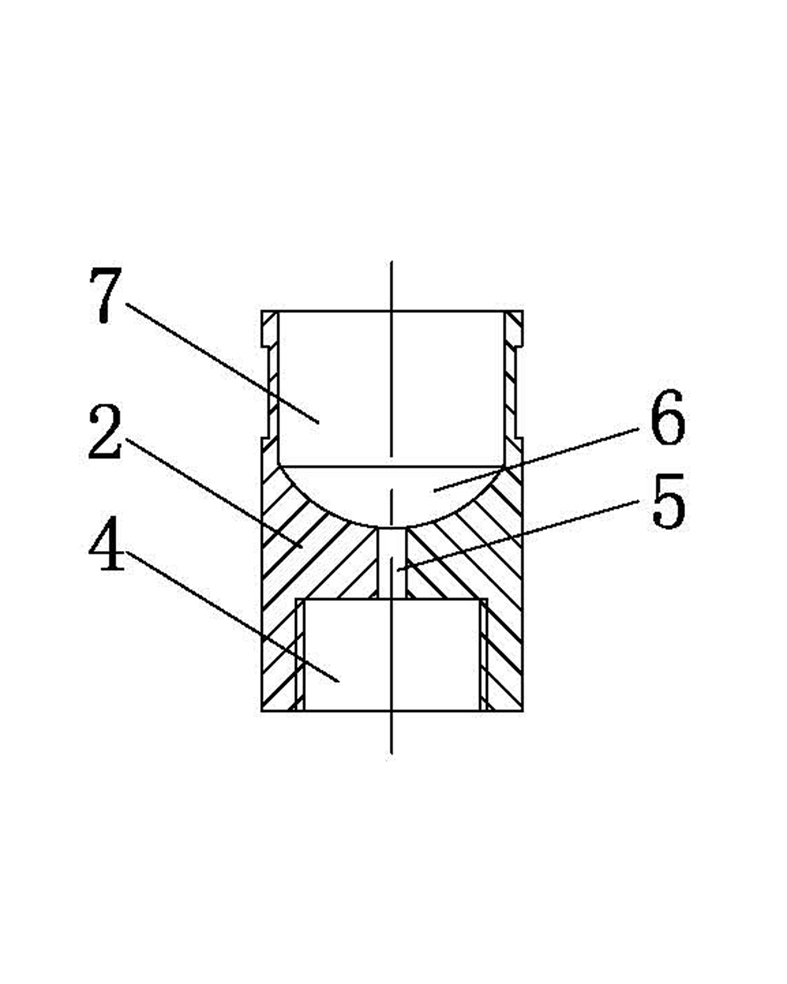

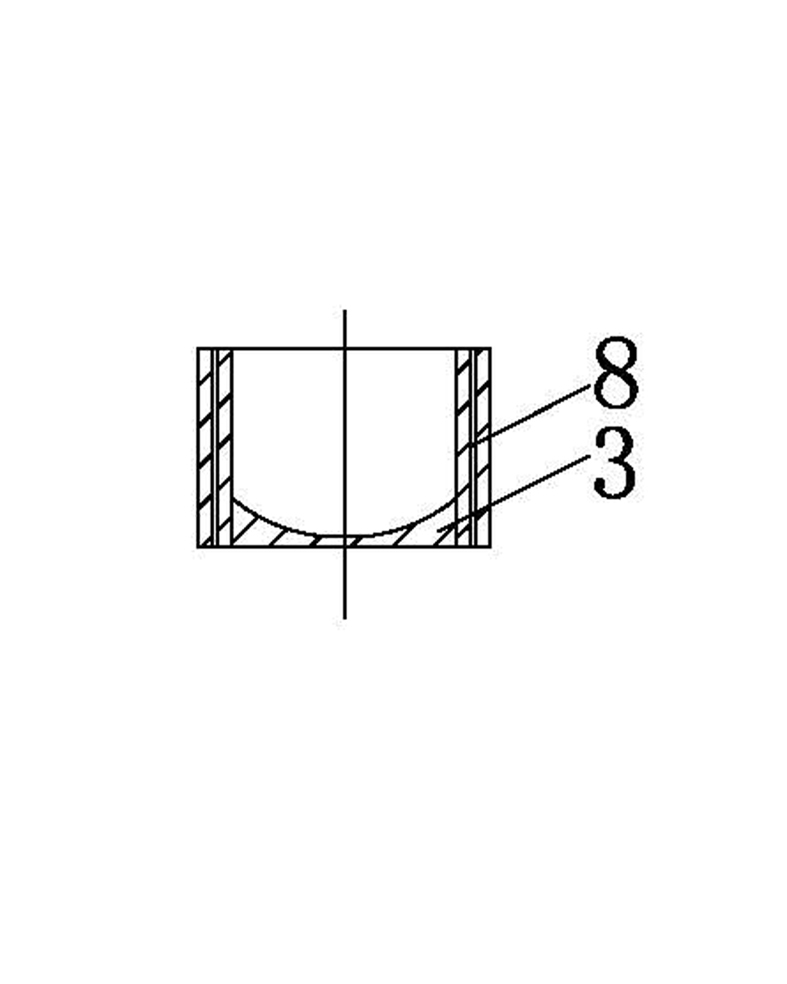

[0019] Such as figure 1 A recoating device for weld lugs of metal cans shown includes an elastic bottle body 1 , a connecting piece 2 installed on the upper part of the elastic bottle body 1 , and a cover body 3 installed on the upper part of the connecting piece 2 . The elastic bottle body 1 can utilize common plastic products with a certain degree of elasticity in daily life; the lower part of the connector 2 has an interface 4 that matches the mouth of the elastic bottle body 1, and the middle part of the connector 2 has a U-shaped hollow part 6, The upper part of the connector 2 has a receiving portion 7, and the inside of the connector 2 is provided with a diversion hole 5, and the diversion hole 5 communicates the interface 4 with the hollow part 6, such as figure 2 Shown; On the upper wall of cover body 3, paint hole 8 is opened, as image 3 , 4 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com