Environmental-friendly diatom ooze inner wall latex paint and preparation method thereof

A technology for interior wall latex paint and diatom mud, applied in latex paint, coating and other directions, can solve problems such as difficulty in ensuring the environmental protection performance of diatom mud interior wall latex paint, and achieve stable coating performance, strong adhesion, and convenience. repaint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

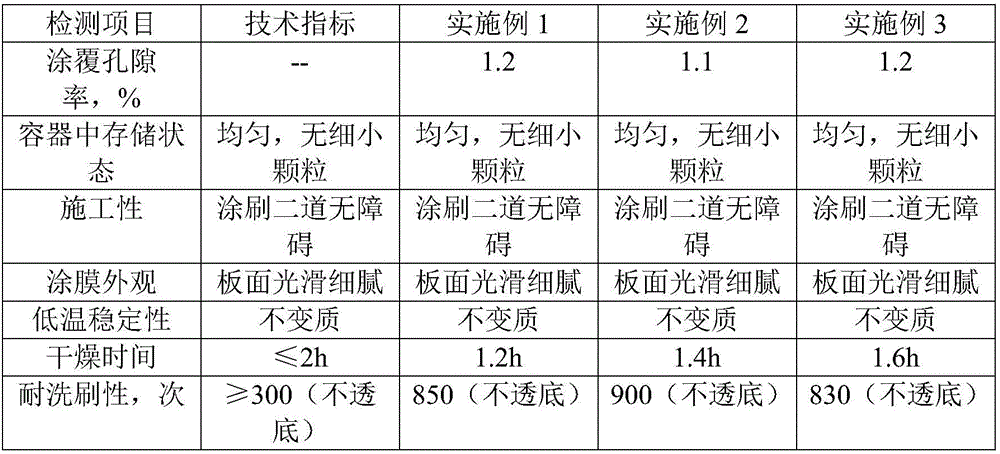

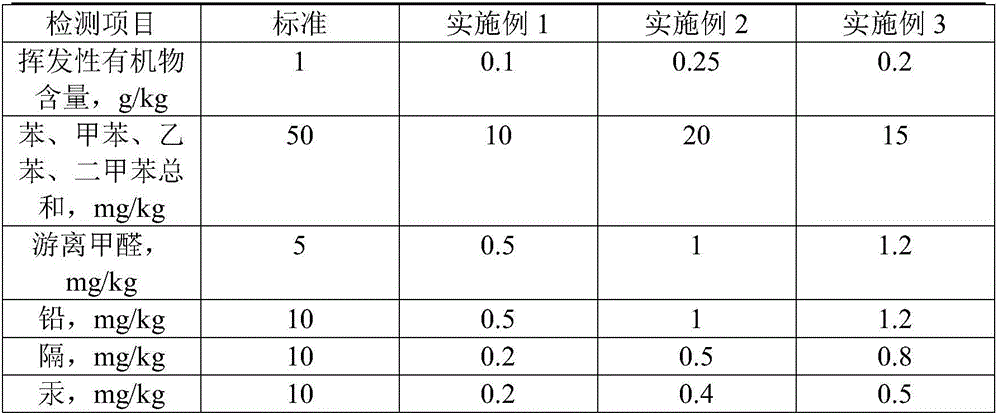

Examples

Embodiment 1

[0030] An environmentally friendly diatom mud latex paint for interior walls, prepared from the following components in weight percent: 12% styrene-acrylic emulsion, 15% diatomaceous earth, 6% titanium dioxide, Dow chemical wetting and dispersing agent CF-10 0.1 %, polyurethane 0.5%, thickener 1%, filler 38%, defoamer 0.4%, ethanol 1%, alkoxy acid sodium salt 0.5%, antifungal agent 0.3%, water 25.2%. The thickener in the present embodiment is the mixture of hydroxyethyl cellulose, hydroxymethyl cellulose, polyurethane thickener; The filler in the present embodiment is silicon dioxide, talcum powder, heavy calcium powder, light calcium powder The mixture; the defoamer in this embodiment is a mixture of silicone and mineral oil.

Embodiment 2

[0032] A diatom mud environment-friendly interior wall latex paint, which is prepared from the following components in weight percentage: 18% styrene-acrylic emulsion, 10% diatomaceous earth, 3% titanium dioxide, and Dow chemical wetting and dispersing agent CF-100.5% , acrylate 0.1%, thickener 0.5%, filler 25%, defoamer 0.2%, ethanol 1.5%, alkoxy acid sodium salt 1%, antifungal agent 0.6%, water 39.6%. The thickener in the present embodiment is the mixture of hydroxyethyl cellulose and hydroxymethyl cellulose; the filler in the present embodiment is the mixture of silicon dioxide, talcum powder, wollastonite, mica powder; in the present embodiment The best defoamer is a mixture of silicone and mineral oil.

Embodiment 3

[0034] A diatom mud environment-friendly interior wall latex paint, which is prepared from the following components in weight percentage: 15% styrene-acrylic emulsion, 13% diatomaceous earth, 5% titanium dioxide, and Dow chemical wetting and dispersing agent CF-100.4% , polyester 0.3%, thickener 0.8%, filler 32.5%, defoamer 0.3%, ethanol 1.3%, alkoxy acid sodium salt 0.9%, antifungal agent 0.5%, water 30%. The thickener in the present embodiment is the mixture of hydroxyethyl cellulose and polyurethane thickener; the filler in the present embodiment is the mixture of silicon dioxide, wollastonite, heavy calcium powder, and light calcium powder; The defoamer in the example is a mixture of silicone and mineral oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com