Production method of moisture-absorption and air-permeation underwear for infants

A moisture-absorbing, breathable, production method technology, applied in the field of textile products, can solve problems such as easy to cause allergies, achieve excellent inhibition effect, increase supplementary effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

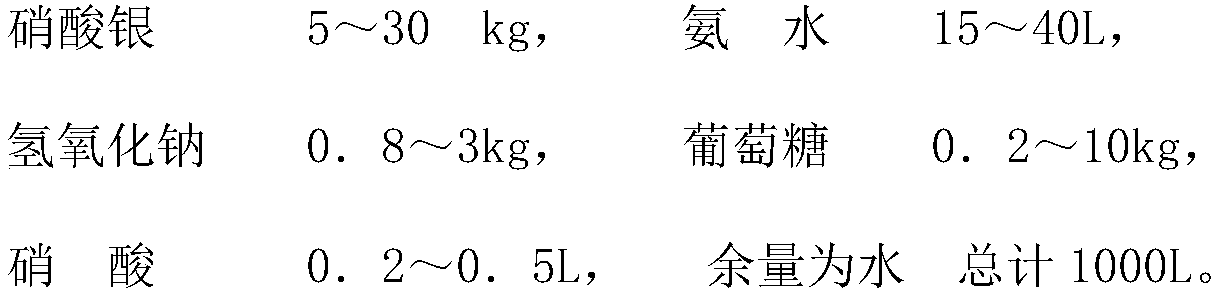

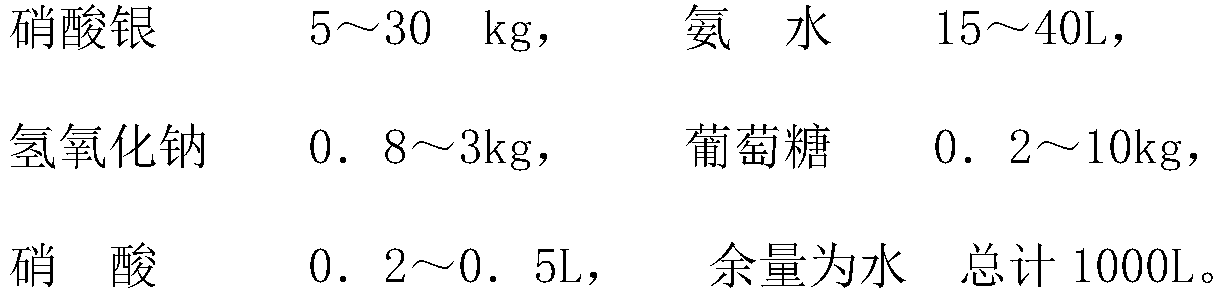

Method used

Image

Examples

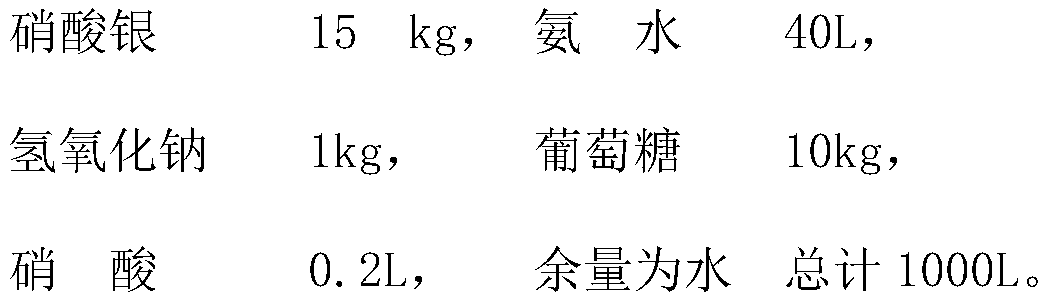

Embodiment 1

[0020] This embodiment provides a method for producing moisture-absorbing and breathable infant underwear, comprising the following steps:

[0021] Step 1: Treat the fabric in a hydrophilic finishing agent with a pH of 5 at a temperature of 38°C, gradually raise the temperature to 80°C and add disperse dyes formulated with silicone oil, and keep at this temperature for 10 minutes to obtain hydrophilic cotton fibers;

[0022] Step 2: Let the fabric be treated in a hydrophilic finishing agent with a pH of 5 at a temperature of 38°C, gradually raise the temperature to 80°C and add disperse dyes formulated with silicone oil, and keep at this temperature for 10 minutes to obtain hydrophobic cotton fibers;

[0023] Step 3: After washing the hydrophilic cotton fiber and the hydrophobic cotton fiber, they are both dried at 150°C;

[0024] Step 4: Put the dried hydrophilic cotton fiber and hydrophobic cotton fiber on the air permeability meter, and measure the rate at which the gas pas...

Embodiment 2

[0034] This embodiment provides a method for producing moisture-absorbing and breathable infant underwear, comprising the following steps:

[0035] Step 1: Treat the fabric in a hydrophilic finishing agent with a pH of 5.5 at a temperature of 40°C, gradually raise the temperature to 80°C and add disperse dyes formulated with silicone oil, and keep at this temperature for 10 minutes to obtain hydrophilic cotton fibers;

[0036] Step 2: Let the fabric be treated in a hydrophilic finishing agent with a pH of 5.5 at a temperature of 40°C, gradually raise the temperature to 80°C and add disperse dyes formulated with silicone oil, and keep at this temperature for 10 minutes to obtain hydrophobic cotton fibers;

[0037] Step 3: After washing the hydrophilic cotton fiber and the hydrophobic cotton fiber, both are dried at 170°C;

[0038] Step 4: Put the dried hydrophilic cotton fiber and hydrophobic cotton fiber on the air permeability meter, and measure the rate at which the gas pass...

Embodiment 3

[0048] This embodiment provides a method for producing moisture-absorbing and breathable infant underwear, comprising the following steps:

[0049] Step 1: Treat the fabric in a hydrophilic finishing agent with a pH of 5 at a temperature of 41°C, gradually raise the temperature to 80°C and add disperse dyes formulated with silicone oil, and keep at this temperature for 10 minutes to obtain hydrophilic cotton fibers;

[0050] Step 2: Let the fabric be treated in a hydrophilic finishing agent with a pH of 5 at a temperature of 41°C, gradually raise the temperature to 80°C and add disperse dyes formulated with silicone oil, and keep at this temperature for 10 minutes to obtain hydrophobic cotton fibers;

[0051] Step 3: After washing the hydrophilic cotton fiber and the hydrophobic cotton fiber, they are both dried at 150°C;

[0052] Step 4: Put the dried hydrophilic cotton fiber and hydrophobic cotton fiber on the air permeability meter, and measure the rate at which the gas pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com