Synthetic latex diatom inner wall emulsion paint and preparation method thereof

A technology of interior latex paint and synthetic emulsion, applied in the field of interior wall latex paint, can solve the problems of blocked adsorption and release of negative ions, incompatibility of latex paint with scrub resistance, poor air permeability, poor environmental protection and safety, etc., to achieve Good washing resistance, natural environmental sustainability, and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

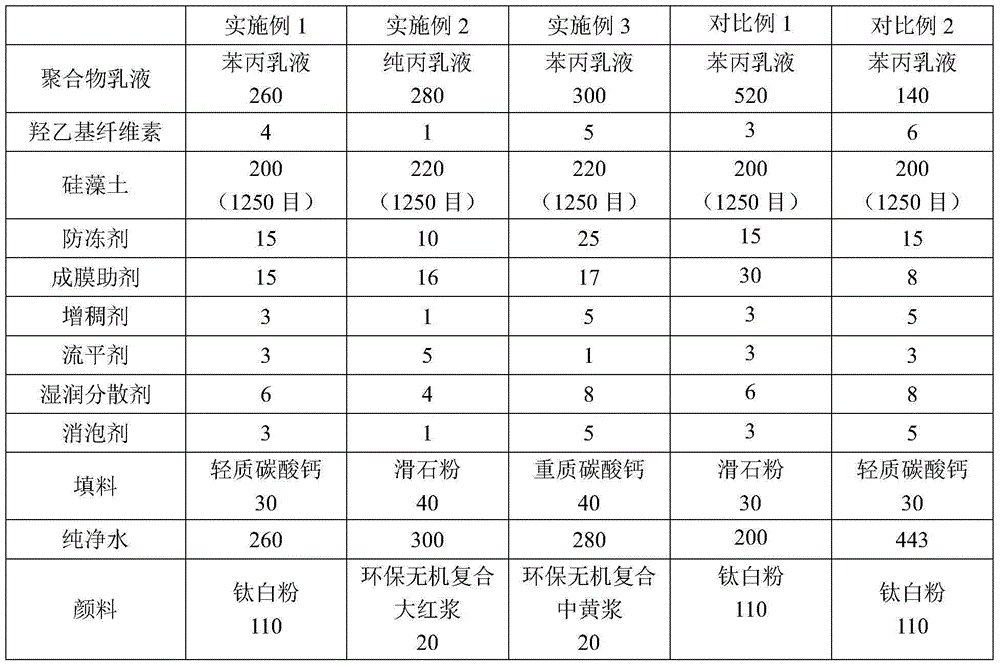

[0046] Prepare synthetic emulsion diatom white interior wall latex paint by the formula weight part of table 1, comprise the following steps:

[0047] a) Prepare raw materials according to the weight parts set by the formula, put hydroxyethyl cellulose, purified water, antifreeze, titanium dioxide, diatomaceous earth, calcium carbonate, and talcum powder into the container in turn and stir at a high speed of 1400-1600 rpm, After stirring evenly, grind on a horizontal sand mill until the fineness is ≤30μm, then transfer it to a mixing container, reduce the speed to 800 rpm, add polymer emulsion, film-forming aids, and leveling agents , add a thickener to adjust the viscosity required by the customer.

[0048] b) Test-filter-package-sample retention.

Embodiment 2

[0050] The adjustment of the formula ratio of this embodiment is shown in Table 1. The specific implementation process is basically the same as that of Example 1, the only difference being that the high-speed stirring speed is 1200-1400 rpm, and the stirring time is 30 minutes.

Embodiment 3

[0052] The adjustment of the formula ratio of this embodiment is shown in Table 1. The specific implementation process is basically the same as that of Example 1, the only difference being that the high-speed stirring speed is 1200-1400 revolutions per minute, and the stirring time is 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com