Metal template coating, preparation method thereof and coating production line thereof

A coating production line and metal template technology, which is applied in the field of materials, can solve problems such as metal template corrosion, and achieve the effects of less pollution, dense paint, and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

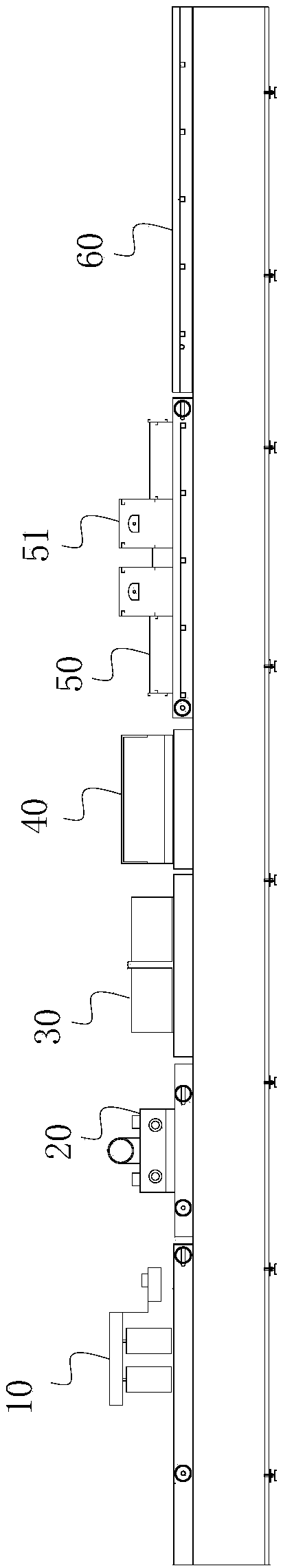

Image

Examples

Embodiment 1

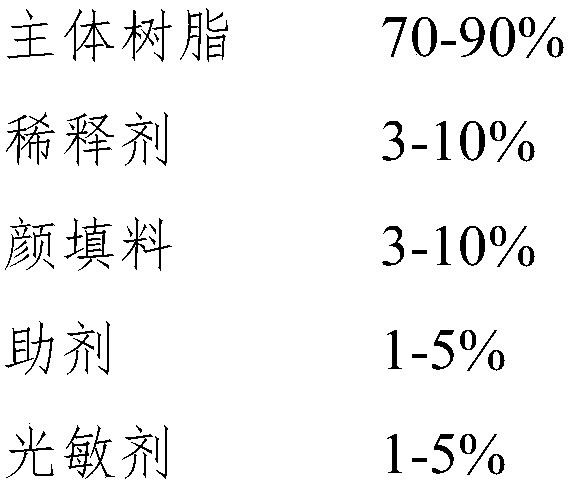

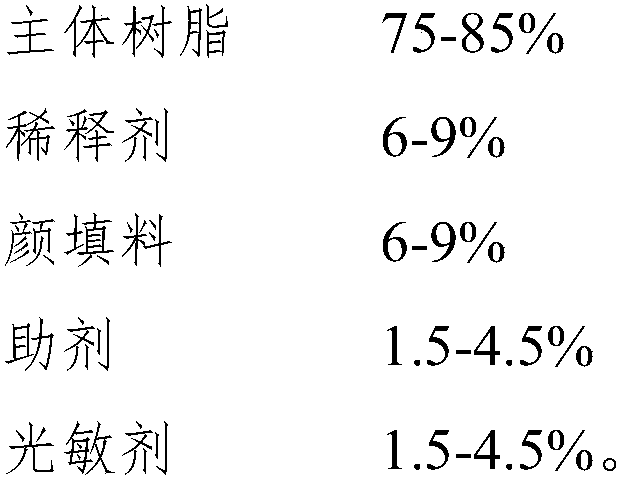

[0058] 80% aliphatic urethane acrylate, 8% isobornyl acrylate, 7% pigments and fillers (which include 25% zinc stearate, 25% bentonite, 25% calcium carbonate and 25% talcum) powder), 3% polysiloxane and 2% 2-isopropylthioxanthone were put into the reactor, dispersed at 400r / min for 35min; then dispersed at 950r / min for 60min; Net filter, to be installed.

Embodiment 2

[0060] In order, the mass percentage content is 70% acrylate, 10% 1,6-hexanediol diacrylate, 10% pigments and fillers (including 25% zinc stearate, 25% bentonite, 25% calcium carbonate and 25% talcum powder), 5% unsaturated polyamide and hydroxy acid salt and 5% 1-hydroxycyclohexyl phenyl ketone into the reactor, disperse for 40min with 500r / min rotating speed; then disperse with 900r / min rotating speed for 65min ; After the dispersion is completed, use a 120-mesh filter to filter and wait for installation.

Embodiment 3

[0062] In order, the mass percentage content is 90% aromatic acid methacrylate half ester, 3% tripropylene glycol diacrylate, 3% pigments and fillers (including 25% zinc stearate, 25% bentonite, 25% carbonic acid Calcium and 25% talcum powder), 1% propylene glycol methyl ether and 3% 2-benzyl-2-dimethylamino-1-(4-morpholine phenyl) butanone drop into the reactor, with 550r / min rotating speed Disperse for 45 minutes; then disperse at a speed of 980r / min for 68 minutes; after the dispersion is completed, use a 120-mesh filter to filter and wait for installation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| autoignition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com