High-tensile UV transfer printing adhesive used for 3.5D and application thereof

A transfer printing glue and raw material technology, which is applied in the direction of transferring ink, printing, adhesives, etc. from the original, can solve the problems of high crosslinking density, processing limitations, and lack of recoatability, etc., and achieve excellent flexibility and beautiful texture , Strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

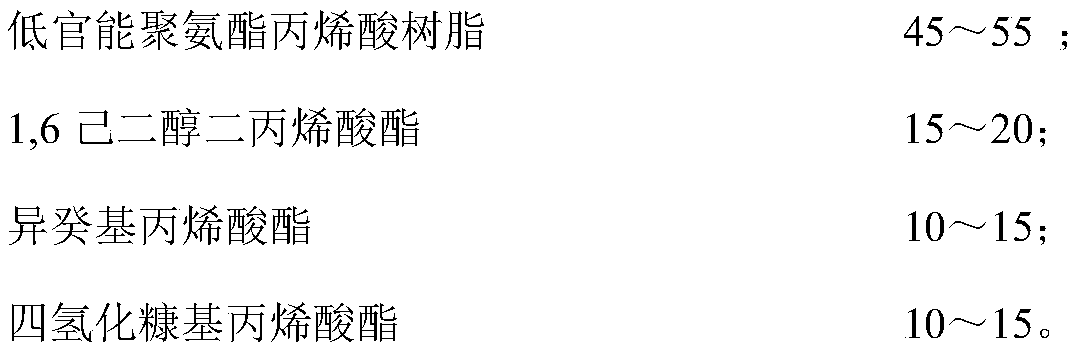

[0027] As an embodiment of the present invention, the raw materials for the preparation of the UV transfer adhesive also include the following components in parts by weight:

[0028] Photosensitizer 3~4.

[0029] As an embodiment of the present invention, the raw materials for the preparation of the UV transfer adhesive also include the following components in parts by weight:

[0030] Inhibitor 0.1.

[0031] As an embodiment of the present invention, the raw materials for the preparation of the UV transfer adhesive consist of the following components in parts by weight:

[0032]

[0033] Low functional polyurethane acrylic resin

[0034] Urethane acrylates contain acrylic functional groups and urethane linkages in their molecules.

[0035] The functionality of the low-functional polyurethane acrylic resin in the present invention is 2-3, more preferably 2.

[0036] As an embodiment of the present invention, the low-functional polyurethane acrylic resin has a TG point ...

Embodiment

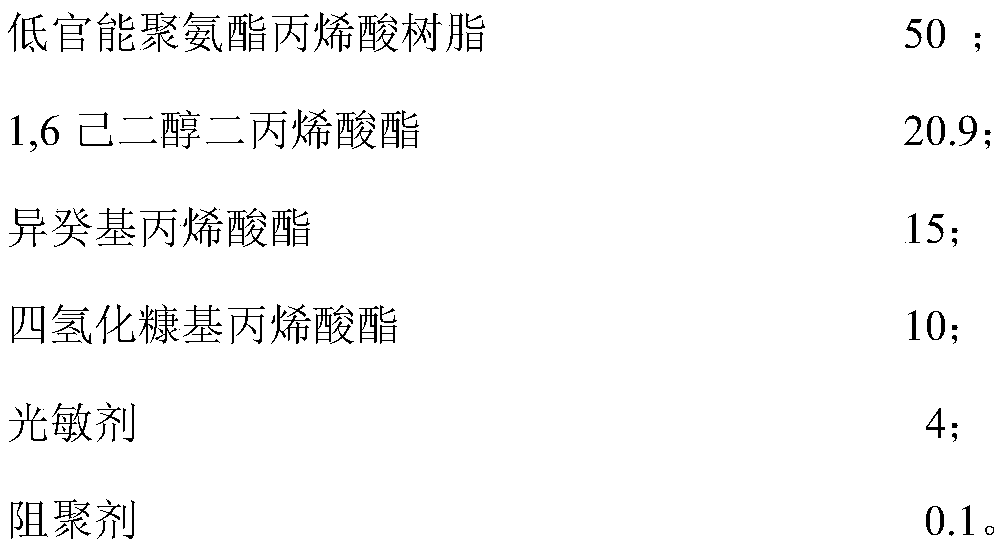

[0077] The present invention is described in further detail as follows by embodiment 1-4 as shown in table 1:

[0078] Table 1

[0079]

[0080]

[0081] Wherein, the functionality of the low-functional urethane acrylate is 2, its TG point is -23°C, the acid value is ≦2mgKOH / g, the viscosity is 13000-16000cpa.s / 60°, the molecular weight is 8800g / mol, and the elongation is 340 %; The trade mark of described low-functional urethane acrylate is three links ST8052.

[0082] The acid value of the 1,6-hexanediol diacrylate is 0.2mgKOH / g, the refractive index is 1.455nD / 25°C, and the molecular weight is 226g / mol. The brand of the 1,6-hexanediol diacrylate is Shencheng EM2021.

[0083] The acid value of the isodecyl acrylate is 0.5mgKOH / g, the refractive index is 1.438nD / 25°C, and the molecular weight is 211g / mol. The grade of the isodecyl acrylate is Shencheng EM2191.

[0084] The acid value of the tetrahydrofurfuryl acrylate is 0.5mgKOH / g, the refractive index is 1.455nD / 25°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com