Corrosion-resistant coating for metal lamp post and preparation method of corrosion-resistant coating

A technology for anti-corrosion coatings and light poles, applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of metal light pole coatings such as wear resistance, aging resistance and low rust resistance, and achieve excellent anti-corrosion performance and excellent water resistance , repainted good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

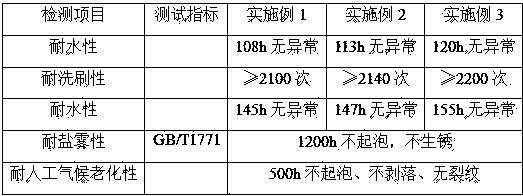

Examples

Embodiment 1

[0009] This embodiment provides an anti-corrosion coating for metal light poles, which contains the following components in parts by mass: 18 parts of petroleum resin, 2 parts of alkyd resin, 18 parts of acrylic resin, 12 parts of dibutyl phthalate, triphosphite 1.1 parts of phenyl ester, 20 parts of xylene, 35 parts of ethyl acetate, 5 parts of talc, 0.4 part of maleic acid, 15 parts of pigment, 9 parts of kaolin, 13 parts of aluminum oxide, and 4 parts of ultraviolet absorber.

[0010] The preparation steps of an anti-corrosion coating for a metal light pole are as follows: firstly mix petroleum resin, alkyd resin, acrylic resin, xylene and ethyl acetate evenly, then add dibutyl phthalate, triphenyl phosphite, Talcum powder, maleic acid, pigment, kaolin, aluminum oxide and ultraviolet absorber are mixed evenly to obtain the finished product.

Embodiment 2

[0012] This embodiment provides an anti-corrosion coating for metal light poles, which contains the following components in parts by mass: 8 parts of petroleum resin, 0.5 parts of alkyd resin, 10 parts of acrylic resin, 3 parts of dibutyl phthalate, triphosphite 0.5 parts of phenyl ester, 10 parts of xylene, 23 parts of ethyl acetate, 3 parts of talc, 0.2 part of maleic acid, 8.7 parts of pigment, 3 parts of kaolin, 5 parts of aluminum oxide, and 1.5 parts of ultraviolet absorber.

[0013] The preparation steps of an anti-corrosion coating for a metal light pole are as follows: firstly mix petroleum resin, alkyd resin, acrylic resin, xylene and ethyl acetate evenly, then add dibutyl phthalate, triphenyl phosphite, Talcum powder, maleic acid, pigment, kaolin, aluminum oxide and ultraviolet absorber are mixed evenly to obtain the finished product.

Embodiment 3

[0015] This embodiment provides an anti-corrosion coating for metal light poles, which contains the following components in parts by mass: 13 parts of petroleum resin, 1.2 parts of alkyd resin, 14 parts of acrylic resin, 7.5 parts of dibutyl phthalate, triphosphite 0.8 parts of phenyl ester, 15 parts of xylene, 29 parts of ethyl acetate, 4 parts of talc, 0.3 part of maleic acid, 11.8 parts of pigment, 6 parts of kaolin, 9 parts of aluminum oxide, and 2.75 parts of ultraviolet absorber.

[0016] The preparation steps of an anti-corrosion coating for a metal light pole are as follows: firstly mix petroleum resin, alkyd resin, acrylic resin, xylene and ethyl acetate evenly, then add dibutyl phthalate, triphenyl phosphite, Talcum powder, maleic acid, pigment, kaolin, aluminum oxide and ultraviolet absorber are mixed evenly to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com