A road marking material and construction method based on phosphorus and magnesium materials

A road marking and construction method technology, applied in the field of transportation, can solve the problems of comprehensive cost, construction operation intensity, technological requirements, environmental protection, difficult repainting construction, large environmental pollution, etc., and achieve controllable setting time , Intensity negative impact is small, the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

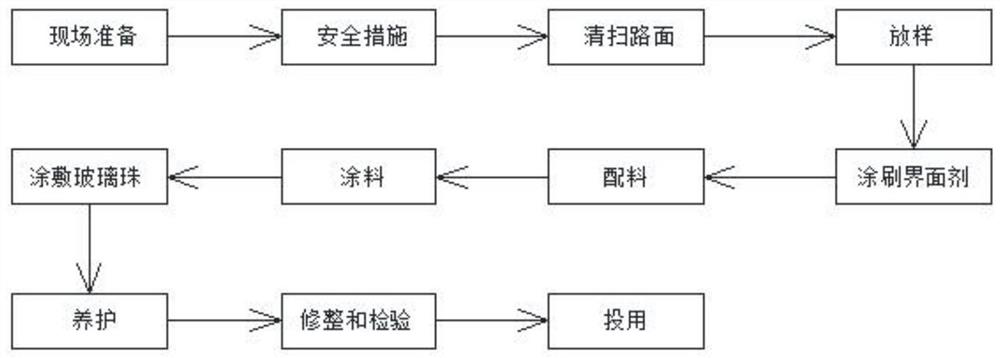

Method used

Image

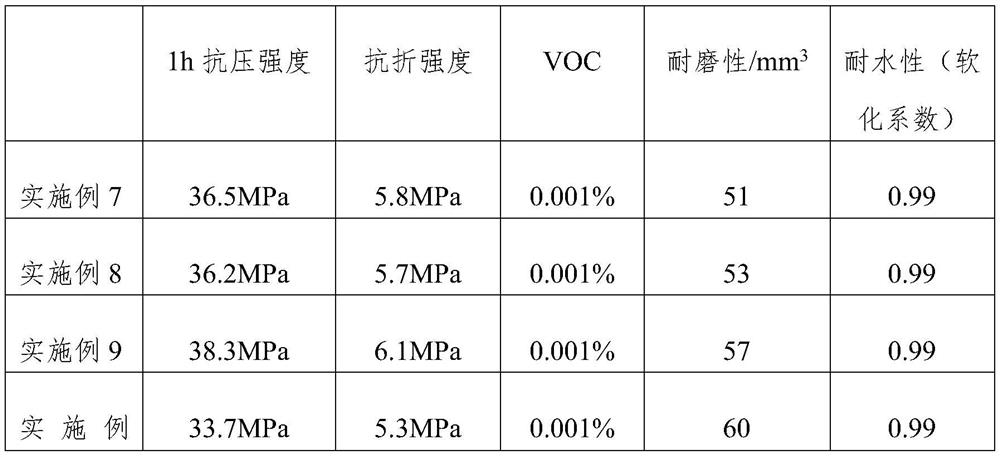

Examples

Embodiment 1

[0048] The present embodiment provides a road marking material based on phosphorus-magnesium material, which is composed of phosphorus-magnesium material and glass beads, and by weight: magnesium phosphate cement 120kg, admixture 15kg, admixture 15kg, inorganic pigment 5kg, Glass beads 15kg;

[0049] Wherein, the magnesium phosphate cement is composed of dead-burned magnesium oxide and monoammonium phosphate in a mass ratio of 4:1;

[0050] The dead-burned magnesia is calcined magnesite at a temperature of 1600° C. until the magnesia content is 95% and the particle size is 400 mesh;

[0051] Described monoammonium phosphate, its nutrient content is 58%, and particle size is 400 orders;

[0052] The admixture is borax, defoamer and water reducing agent; the purity of borax is 95% by mass percentage, and the particle size is 400 mesh; the defoamer is organic silicon powder defoamer;

[0053] The admixture is composed of fly ash and metakaolin in a mass ratio of 4:1;

[0054] ...

Embodiment 2

[0059] This embodiment provides a road marking material based on phosphorus magnesium material, which is composed of phosphorus magnesium material and glass beads, and by weight: magnesium phosphate cement 80kg, admixture 2kg, admixture 10kg, inorganic pigment 0.8kg , glass beads 5kg;

[0060] Wherein, the magnesium phosphate cement is composed of dead-burned magnesium oxide and monoammonium phosphate in a mass ratio of 1:1;

[0061] The dead-burned magnesia is calcined magnesite at a temperature of 2000°C until the magnesite content is 88% and the particle size is 60 mesh;

[0062] The monoammonium phosphate has a nutrient content of 65% and a particle size of 60 mesh;

[0063] The admixture is borax, a defoamer and a water reducer; the purity of the borax is 95% by mass percentage, and the particle size is 60 mesh; the defoamer is an organosilicon powder defoamer;

[0064] The admixture is composed of fly ash and metakaolin in a mass ratio of 2:1;

[0065] The fly ash is ...

Embodiment 3

[0070] This embodiment provides a road marking material based on phosphorus magnesium material, which is composed of phosphorus magnesium material and glass beads, and by weight: magnesium phosphate cement 100kg, admixture 8kg, admixture 12kg, inorganic pigment 2.5kg , glass beads 10kg;

[0071] Wherein, the magnesium phosphate cement is composed of dead-burned magnesium oxide and monoammonium phosphate in a mass ratio of 2:1;

[0072] The dead-burned magnesia is calcined magnesite at a temperature of 1850°C until the magnesia content is 90% and the particle size is 200 mesh;

[0073] Described monoammonium phosphate, its nutrient content is 68%, and particle size is 300 orders;

[0074] The admixture is borax, defoamer and water reducer; the purity of borax is 95% by mass percentage, and the particle size is 220 mesh; the defoamer is organic silicon powder defoamer;

[0075] The admixture is composed of fly ash and metakaolin in a mass ratio of 3:1;

[0076] The fly ash is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com