UV gloss oil as well as preparation method and application thereof

A varnish and photoinitiator technology, used in coatings, polyurea/polyurethane coatings, etc., can solve problems such as hindering the further application of UV varnish, affecting the application effect of printed products, and damaging the health of operators, and achieves good flow. Flat effect, good recoating effect, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

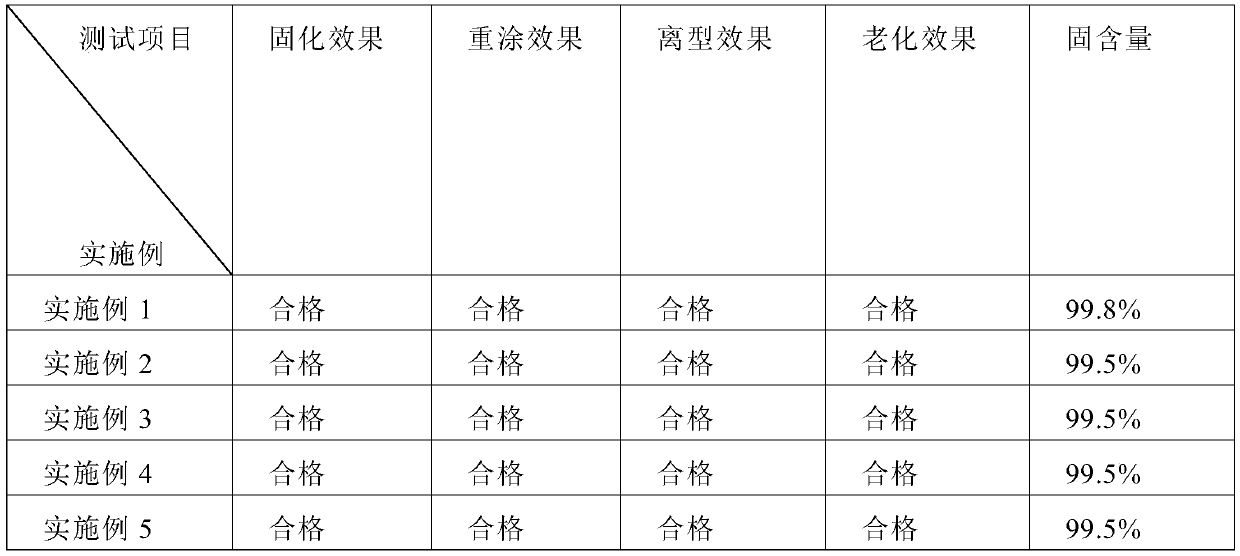

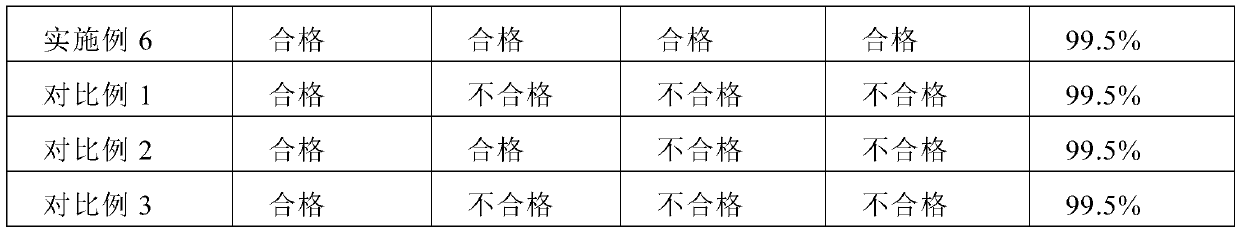

Examples

preparation example Construction

[0057] The present invention also provides the preparation method of above-mentioned any described UV varnish, and this preparation method comprises the following steps:

[0058] Mix part of the monomer with the photoinitiator, heat and keep stirring until the photoinitiator is fully dissolved in the monomer. In actual operation, the heating temperature and stirring conditions can be controlled according to the properties of the photoinitiator used, for example, stirring at 500rpm / min for 30min or so, and heated to 120°C to fully dissolve the photoinitiator to obtain mixture A;

[0059] Mix the leveling agent with some monomers, keep stirring to fully disperse the leveling agent, and control the stirring at 600rpm / min for about 30min to obtain the mixture B.

[0060] Mix the oligomer, mixture A, mixture B and the remaining monomer, stir at a speed of 400r / min for 20min, and filter with a 200-mesh filter to obtain a UV varnish product.

[0061] In another embodiment, when the ...

Embodiment 1

[0067] Based on the total amount of raw materials, the raw material composition of UV varnish, the weight percentage of each component and the molecular weight of some components are as follows:

[0068] Oligomer: 35%

[0069] Difunctional polyurethane acrylate oligomer with a molecular weight of 4100;

[0070] Monomer: 56%

[0071] 49% trimethylolpropane triacrylate, 7% tripropylene glycol diacrylate;

[0072] Leveling agent: 3%

[0073] Cellulose acetate butyrate (Eastman CAB-551-0.01);

[0074] Photoinitiator: 6%

[0075] 5% 2-hydroxy-methylphenylpropanone, 1% 2,4,6-trimethylbenzoyl-benzhydrylphosphine oxide.

[0076] The preparation method of UV varnish is as follows:

[0077] 1) Mix the monomer and the photoinitiator at a ratio of 1:1, stir at 500rpm / min for about 30min, and heat to about 120°C to fully dissolve the photoinitiator to obtain mixture A;

[0078] 2) Mix the leveling agent and the monomer at a ratio of 1:2, and stir at 600rpm / min for about 30 minutes t...

Embodiment 2

[0081] Based on the total amount of raw materials, the raw material composition of UV varnish, the weight percentage of each component and the molecular weight of some components are as follows:

[0082] Oligomer: 40%

[0083] Difunctional polyurethane acrylate oligomer with a molecular weight of 2800;

[0084] Monomer: 42%

[0085] 35% trimethylolpropane triacrylate, 7% tripropylene glycol diacrylate;

[0086] Leveling agent: 3%

[0087] Cellulose acetate butyrate;

[0088] Photoinitiator: 5%

[0089] 3.5% of 2-hydroxy-methylphenylpropanemethanone, 1.5% of 2,4,6-trimethylbenzoyl-benzhydrylphosphine oxide;

[0090] Active amine photosensitizer: 10%.

[0091] The preparation method of Example 2 is basically the same as that of Example 1, except that when the oligomer, mixture A and mixture B are mixed, an active amine photosensitization accelerator is added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com