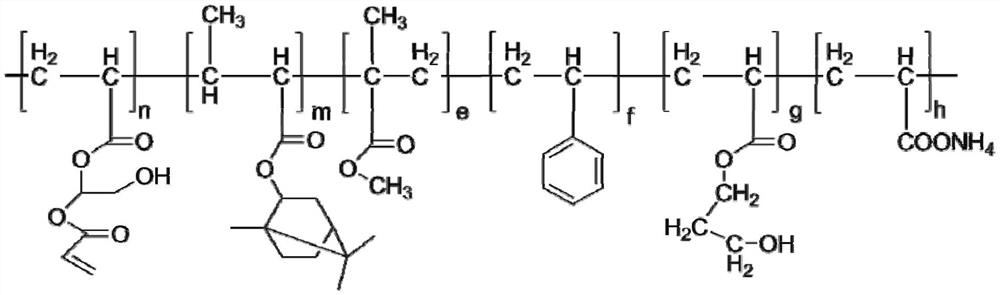

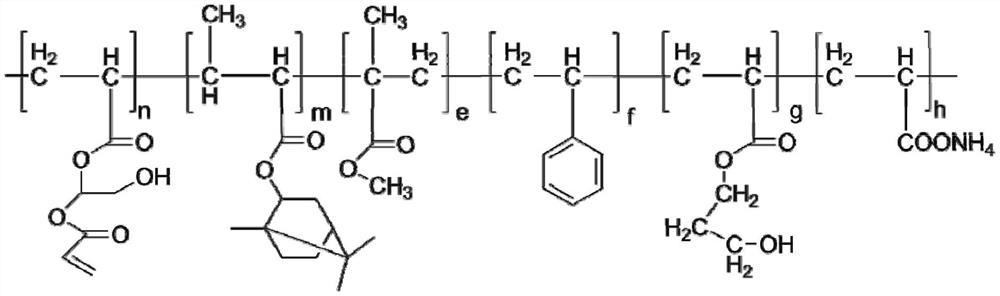

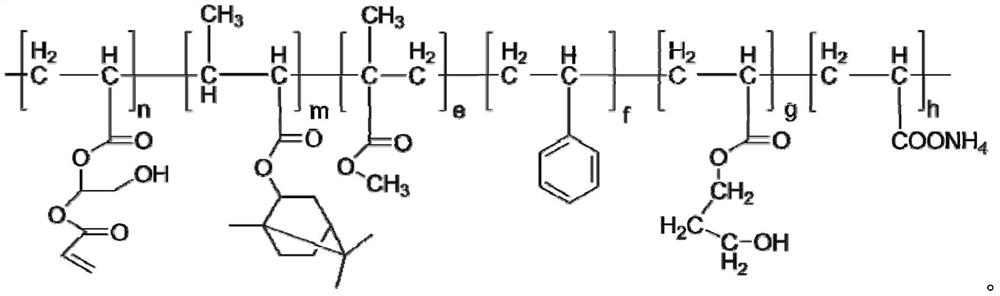

Dual-curing acrylic resin as well as preparation method and application thereof

An acrylic resin, dual-curing technology, used in the field of coatings, can solve the problems of difficult to meet the requirements of wear resistance, poor water resistance and RCA, and long curing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1 of the present invention is: a kind of preparation method of dual curing acrylic resin, comprises the following steps:

[0070] S1. Add 450 g of butyl acetate to a 5000 mL four-neck flask equipped with a stirring device, start stirring and raise the temperature to 110°C.

[0071] S2. Add 130g of isobornyl methacrylate, 100g of acrylic acid, 60g of methyl methacrylate, 150g of styrene, 60g of hydroxyethyl acrylate and 4.4g of initiator di-tert-butyl peroxide into a glass beaker; stir well Then add to the constant pressure dropping funnel.

[0072] S3. After the temperature of the four-neck flask is raised to 110° C., slowly add the materials in the constant pressure dropping funnel dropwise for 4 hours.

[0073] S4. After the addition of the materials in the constant pressure dropping funnel is completed, keep the temperature at 110° C. for 4 hours.

[0074] S5. After the heat preservation is completed, cool the four-neck flask to 100° C., add 10 g of trip...

Embodiment 2

[0081] Embodiment two of the present invention is: a kind of waterborne silver powder paint, comprises A component and B component:

[0082] Wherein, the formula of above-mentioned waterborne silver powder paint A component is as follows:

[0083] 63.4 parts of double curing acrylic resins that embodiment one makes;

[0084] 6 parts of water-based silver powder;

[0085] Dumb powder (Tosoh 1011) 0.6 part;

[0086] Initiator (IGM1173 and IGM184) 2 parts (IGM1173 and IGM184 each part);

[0087] Thickener (Digo 3030) 1 part;

[0088] Dispersant (Digo 750) 0.5 part;

[0089] Wetting agent (Digo 270) 0.5 parts;

[0090] 6 parts of propylene glycol butyl ether;

[0091] 20 parts of water;

[0092] A total of 100 copies.

[0093] Component B of the above water-based silver powder paint is a water-based isocyanate curing agent (Bayhydur 304 from Covestro).

[0094] The weight ratio of component A to component B is 100:10.

[0095] After component A + component B are disperse...

Embodiment 3

[0097] Embodiment three of the present invention is: a kind of waterborne silver powder paint, comprises A component and B component:

[0098] Wherein, the formula of above-mentioned waterborne silver powder paint A component is as follows:

[0099] 63.4 parts of double curing acrylic resins that embodiment one makes;

[0100] 6 parts of water-based silver powder;

[0101] Dumb powder (Tosoh 1011) 0.6 part;

[0102] Initiator (IGM1173 and IGM184) 2 parts (IGM1173 and IGM184 each part);

[0103] Thickener (BYK299) 1 part;

[0104] Dispersant (BYK164) 0.5 parts;

[0105] Wetting agent (Digo 245) 0.5 part;

[0106] 6 parts of propylene glycol butyl ether;

[0107] 20 parts of water;

[0108] A total of 100 copies.

[0109] Component B of the above water-based silver powder paint is a water-based isocyanate curing agent (Bayhydur 304 from Covestro).

[0110] The weight ratio of component A to component B is 100:9.

[0111] After component A + component B are dispersed fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| double bond equivalent | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| double bond equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com