Road lineating material based on phosphorus and magnesium material and preparation method thereof

A road, phosphorus and magnesium technology, applied in the field of materials, can solve the problems of cost price, construction operation intensity, unsatisfactory process requirements, environmental protection, harm to the construction personnel, and affect the health of workers, etc., to achieve controllable solidification time and easy re-use Application, ease of application and formulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

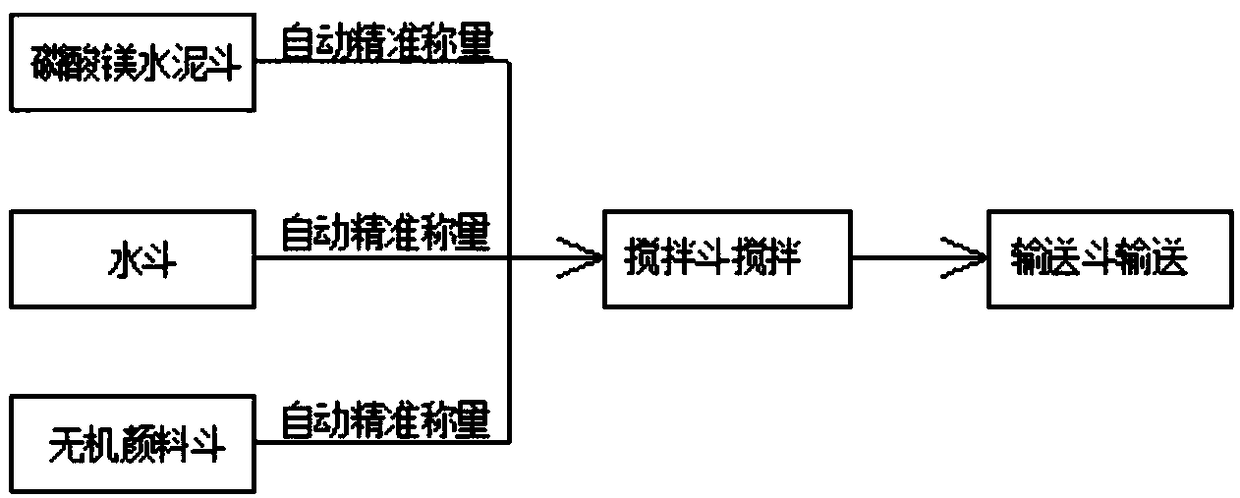

[0071] (1) Batching: According to raw material matching group A, take raw materials such as magnesium phosphate cement, admixture, admixture, pigment, glass microspheres, and add magnesium phosphate cement, admixture, admixture in the magnesium phosphate cement hopper, Water is added to the water bucket, the paint is added to the paint bucket, and the glass beads are stored separately;

[0072] (2) Stirring: the cement mixture in the magnesium phosphate cement hopper, the water in the water hopper and the pigment in the pigment hopper are added to the mixing hopper according to the above ratio through automatic and accurate weighing, and stirred with a stirring motor for 5 minutes;

[0073] (3) Conveying: The stirred material is stored and transported through the high-level difference conveying bucket, and used in conjunction with glass beads, and the stirring bucket is used to stir the next batch of material.

Embodiment 2

[0075] (1) Batching: According to raw material matching group A, take raw materials such as magnesium phosphate cement, admixture, admixture, pigment, glass microspheres, and add magnesium phosphate cement, admixture, admixture in the magnesium phosphate cement hopper, Water is added to the water bucket, the paint is added to the paint bucket, and the glass beads are stored separately;

[0076] (2) Stirring: the cement mixture in the magnesium phosphate cement hopper, the water in the water hopper and the pigment in the paint hopper are added to the mixing hopper by automatic and accurate weighing according to the above ratio, and stirred by a stirring motor for 2.5 minutes;

[0077] (3) Conveying: The stirred material is stored and transported through the high-level difference conveying bucket, and used in conjunction with glass beads, and the stirring bucket is used to stir the next batch of material.

Embodiment 3

[0079] (1) Batching: According to raw material matching group A, take raw materials such as magnesium phosphate cement, admixture, admixture, pigment, glass microspheres, and add magnesium phosphate cement, admixture, admixture in the magnesium phosphate cement hopper, Water is added to the water bucket, the paint is added to the paint bucket, and the glass beads are stored separately;

[0080] (2) Stirring: the cement mixture in the magnesium phosphate cement hopper, the water in the water hopper and the pigment in the pigment hopper are added to the mixing hopper according to the above ratio through automatic and accurate weighing, and stirred with a stirring motor for 7.5 minutes;

[0081] (3) Conveying: The stirred material is stored and transported through the high-level difference conveying bucket, and used in conjunction with glass beads, and the stirring bucket is used to stir the next batch of material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com